Special chain belt for jujube conveying

A technology of chain belt and jujube, applied in the direction of conveyor, application, transportation and packaging, can solve the problems of increasing equipment maintenance cost and high manufacturing cost of conveying mechanism, and achieve the effect of reducing maintenance cost and manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

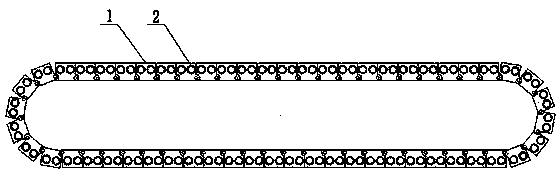

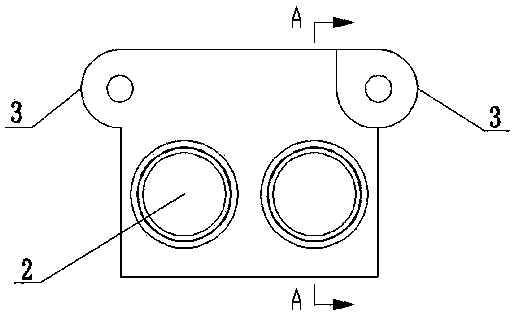

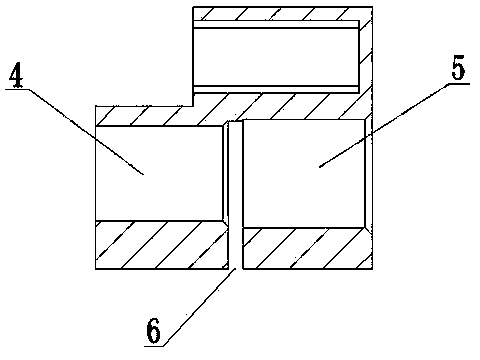

[0018] Such as Figure 1 to Figure 4 As shown, the special chain belt for jujube delivery of the present invention is characterized in that it comprises no less than three chain links 1, and pin lugs 3 are arranged on both sides of the chain link 1, and pin shafts are all arranged in the pin lugs 3. The joint 1 is hinged head-to-tail in turn through the pin lug 3 and the pin shaft to form an endless chain belt. The material-filling hole 2 that is used to hold jujube is arranged on described chain link 1. In this embodiment, the axis of the material holding hole 2 is parallel to the axis of the pin shaft at the hinge point of the chain link 1 . The filling hole 2 is divided into an upper jujube bin 5 and a lower jujube bin 4, and the diameter of the upper jujube bin 5 is greater than the diameter of the lower jujube bin 4, and they are concentrically arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com