removable mold

A detachable mold technology, applied in the field of stamping molds, can solve the problems of scrapping, inability to disassemble, long processing process, etc., and achieve the effects of cost reduction, simple structure, and convenient assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

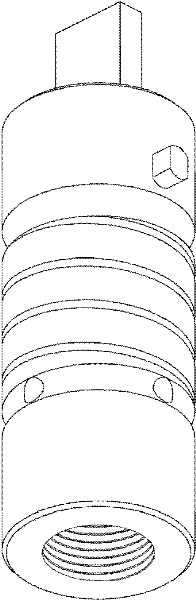

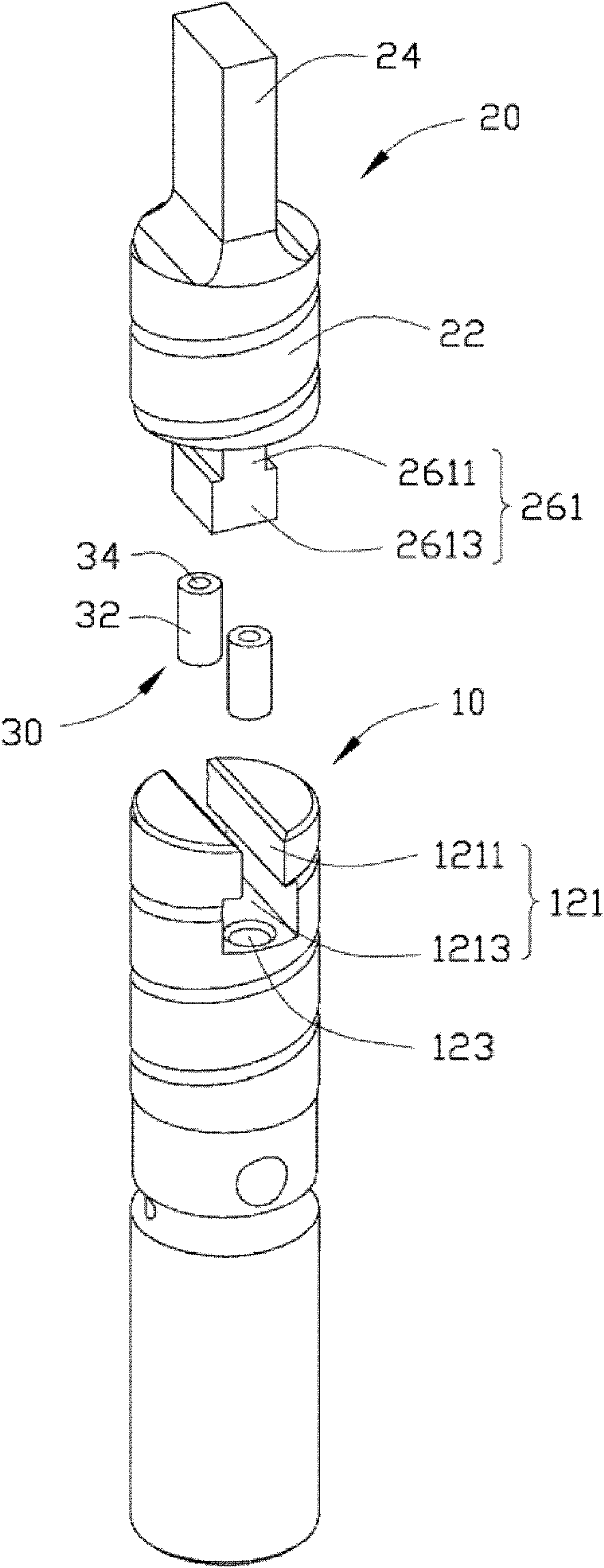

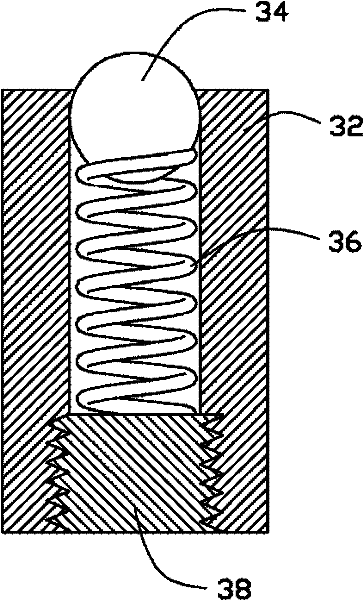

[0028] see figure 2 , The preferred embodiment of the present invention, the detachable mold includes a mold base 10 , a punch 20 and a pair of stoppers 30 .

[0029] The mold base 10 is cylindrical and has a mounting groove 121 on its top. The mounting groove 121 includes a narrower stopper 1211 opened on the top of the mold base 10 and a The wider mounting part 1213 below. The mold base 10 also defines a pair of cylindrical mounting holes 123 downwards at the bottom of the mounting groove 121 for mounting the limiting member 30 .

[0030] The punch 20 includes a cylindrical post 22 , a head 24 protruding upward from the top of the post 22 , and a mounting block 261 protruding downward from the bottom of the post 22 . The mounting block 261 includes a narrow neck 2611 and a wide protrusion 2613 . The width of the neck portion 2611 of the mounting block 261 is equivalent to the width of the limiting portion 1211 of the mounting groove 121 of the mold base 10 . The width o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com