End anchor type spiral steel fire and manufacturing and processing method thereof

A steel fiber and helical technology, which is applied in the field of new end-anchored helical steel fibers and their production and processing, achieves the effects of reliable anchoring, guaranteed mixing quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

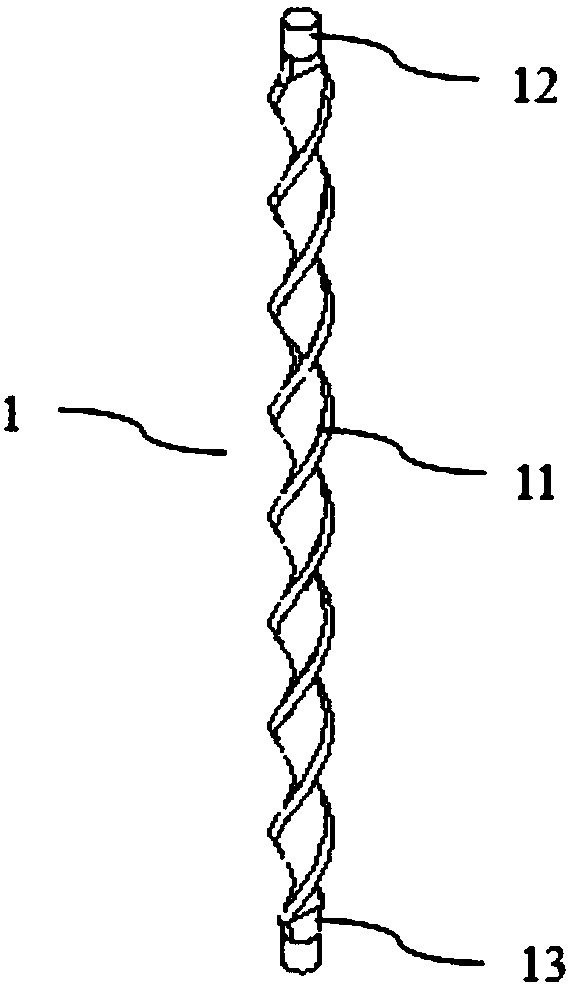

[0029] Such as Figure 1-3 , the end-anchored helical steel fiber 1 shown in the figure includes an intermediate section 12 integrally formed by the same cylindrical steel wire, anchoring ends 11 arranged at both ends of the intermediate section, and a smooth surface for connecting the anchoring end and the intermediate section. The transition section 13, the diameter of the steel wire is 0.5-1mm, the anchoring end keeps a circular cross section with the same diameter as the steel wire, the middle section is the main body of the steel fiber, the middle section is in the shape of a spiral, and the outer contour is a smooth drum-shaped surface, which consists of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com