A low-cost high-strength pipe material and its preparation method

A high-strength, low-cost technology, applied in the field of metal materials, can solve the problems of the rapid increase of the ductile-brittle transition temperature of the alloy, the influence of plasticity, and the influence of the service performance of the alloy, so as to reduce the ductile-brittle transition temperature, ensure oxidation resistance and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

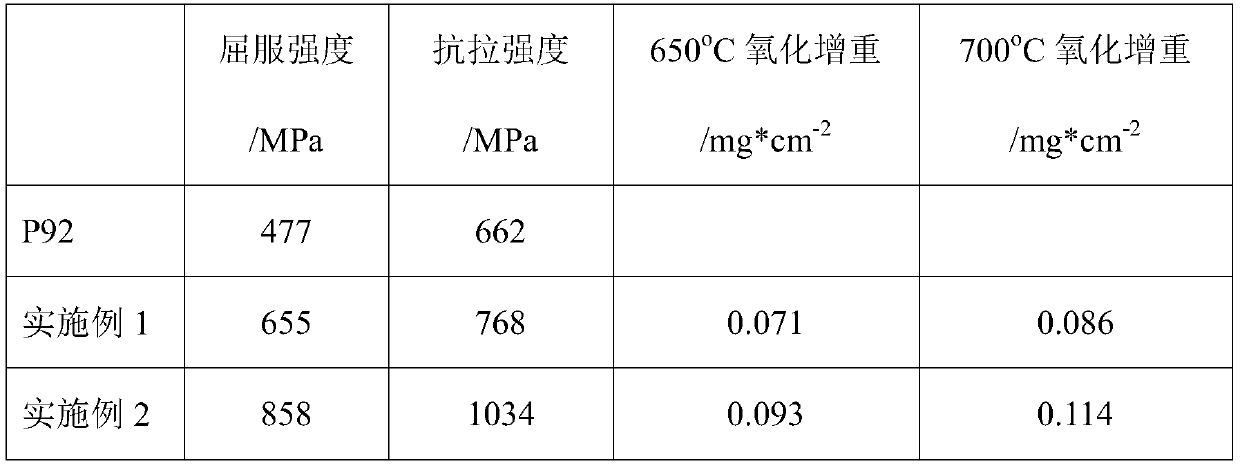

Embodiment 1

[0021] The heat-resistant steel material of this embodiment comprises: C: 0.05%, Ni: 6.0%, Cr: 18%, Al: 3.0%, Ti: 0.2%, Nb: 0.5%, Mo: 0.5%, N: 0.2%, Zr: 0.05%, B: 0.005%, and the balance is Fe.

[0022] The preparation method of the present embodiment comprises the following steps:

[0023] 1) Raw material preparation: The ingredients include by mass percentage: C: 0.05%, Ni: 6.0%, Cr: 18%, Al: 3.0%, Ti: 0.2%, Nb: 0.5%, Mo: 0.5%, N: 0.2 %, Zr: 0.05%, B: 0.005%, and the balance is Fe.

[0024] 2) Melting step: the prepared alloy is melted into alloy mother liquor by using a vacuum induction furnace, and finally prepared into an alloy ingot by suction casting (negative pressure casting process).

[0025] 3) High-temperature hot rolling: After the ingot is formed, the plate is rolled at 1050°C, and the deformation of each rolling pass is not less than 10%, and the final total deformation is not less than 40%.

[0026] 4) Alloy heat treatment: the alloy rolled plate is solution...

Embodiment 2

[0028] The heat-resistant steel material of this embodiment includes: C: 0.05%, Ni: 6.0%, Cr: 18%, Al: 2.0%, Ti: 0.2%, Co: 3%, W: 1.0%, Cu: 1.5%, Zr: 0.05%, B: 0.005%, and the balance is Fe.

[0029] The preparation method of the present embodiment comprises the following steps:

[0030] 1) Raw material preparation: The ingredients include by mass percentage: C: 0.05%, Ni: 6.0%, Cr: 18%, Al: 2.0%, Ti: 0.2%, Co: 3%, W: 1.0%, Cu: 1.5% %, Zr: 0.05%, B: 0.005%, and the balance is Fe.

[0031] 2) Melting step: the prepared alloy is melted into alloy mother liquor by using a vacuum induction furnace, and finally prepared into an alloy ingot by suction casting (negative pressure casting process).

[0032] 3) High-temperature hot rolling: After the ingot is formed, the plate is rolled at 1050°C, and the deformation of each rolling pass is not less than 10%, and the final total deformation is not less than 40%.

[0033] 4) Alloy heat treatment: the alloy rolled plate is solution tre...

Embodiment 3

[0038] The heat-resistant steel material of this embodiment includes: C: 0.03%, Ni: 5%, Cr: 17%, Al: 1.8%, and the balance is Fe;

[0039] The preparation method of the present embodiment comprises the following steps:

[0040] 1) Raw material preparation: carry out alloy preparation according to the above-mentioned composition.

[0041] 2) Melting step: the prepared alloy is melted into alloy mother liquor by using a vacuum induction furnace, and finally prepared into an alloy ingot by suction casting (negative pressure casting process).

[0042] 3) High-temperature hot rolling: After the ingot is formed, the plate is rolled at 850°C, and the deformation of each rolling pass is not less than 10%, and the final total deformation is not less than 40%.

[0043] 4) Alloy heat treatment: The alloy rolled plate is solution treated at 1100°C for 2 hours, then air-cooled, then aged at 700°C for 24 hours, and finally air-cooled to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com