Dust removal device for spring

A mobile device and lifting device technology, which is applied in the field of rust removal devices for springs, can solve the problems of poor rust removal effect, time-consuming and laborious, and easily injured hands of rust removers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

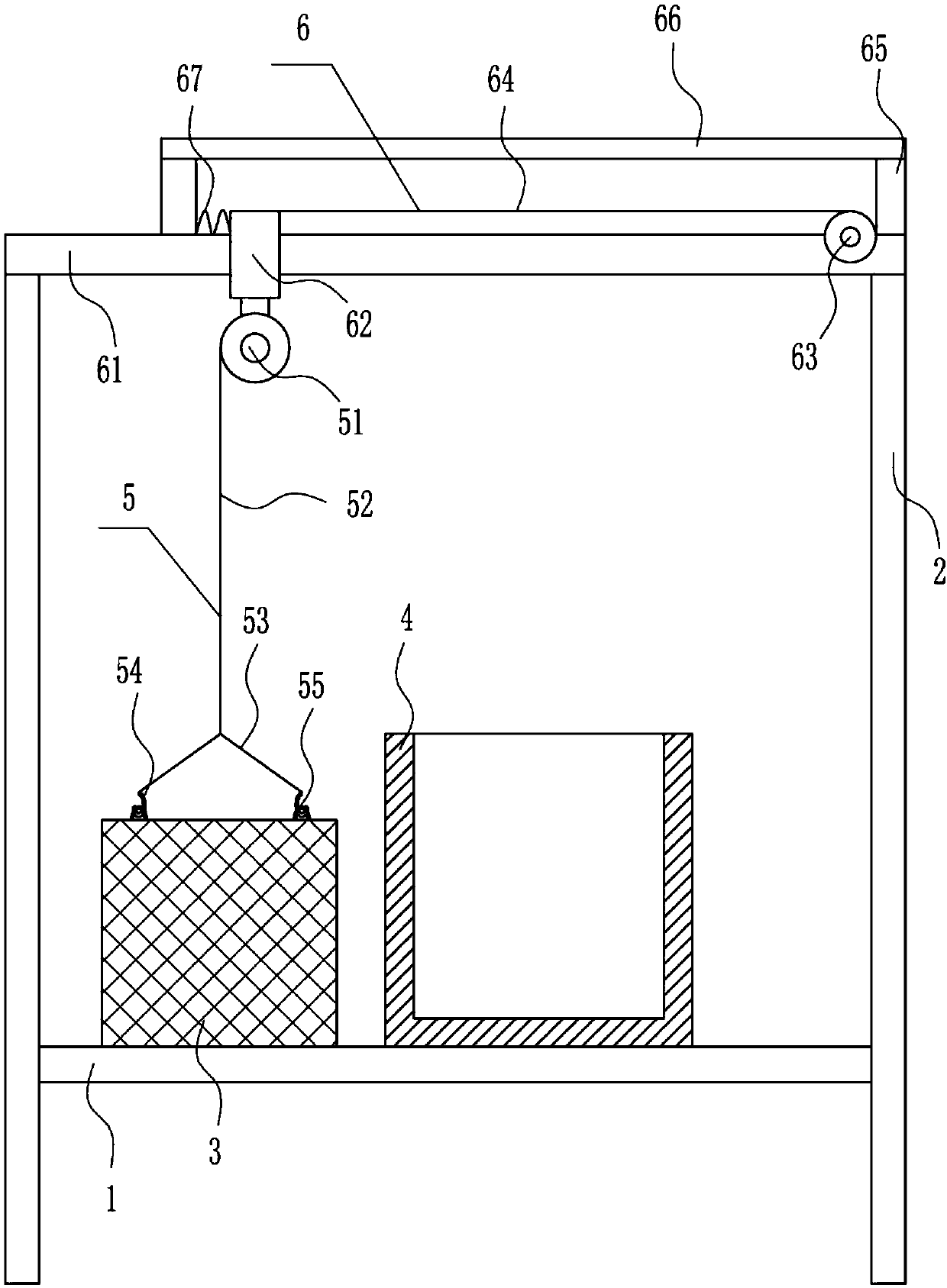

[0035] A kind of derusting device for spring, such as Figure 1-5 As shown, it includes a horizontal plate 1, a support plate 2, a screen frame 3, a frame body 4, a hoisting device 5 and a moving device 6, and the left side and the right side of the horizontal plate 1 are equipped with a support plate 2. A moving device 6 is arranged between the tops of the boards 2, a lifting device 5 is arranged on the moving part of the moving device 6, a screen frame 3 is arranged on the left side of the top of the horizontal board 1, the top of the screen frame 3 is connected with the lifting device 5, and the top of the horizontal board 1 is connected to the lifting device 5. Frame body 4 is installed on the right side.

Embodiment 2

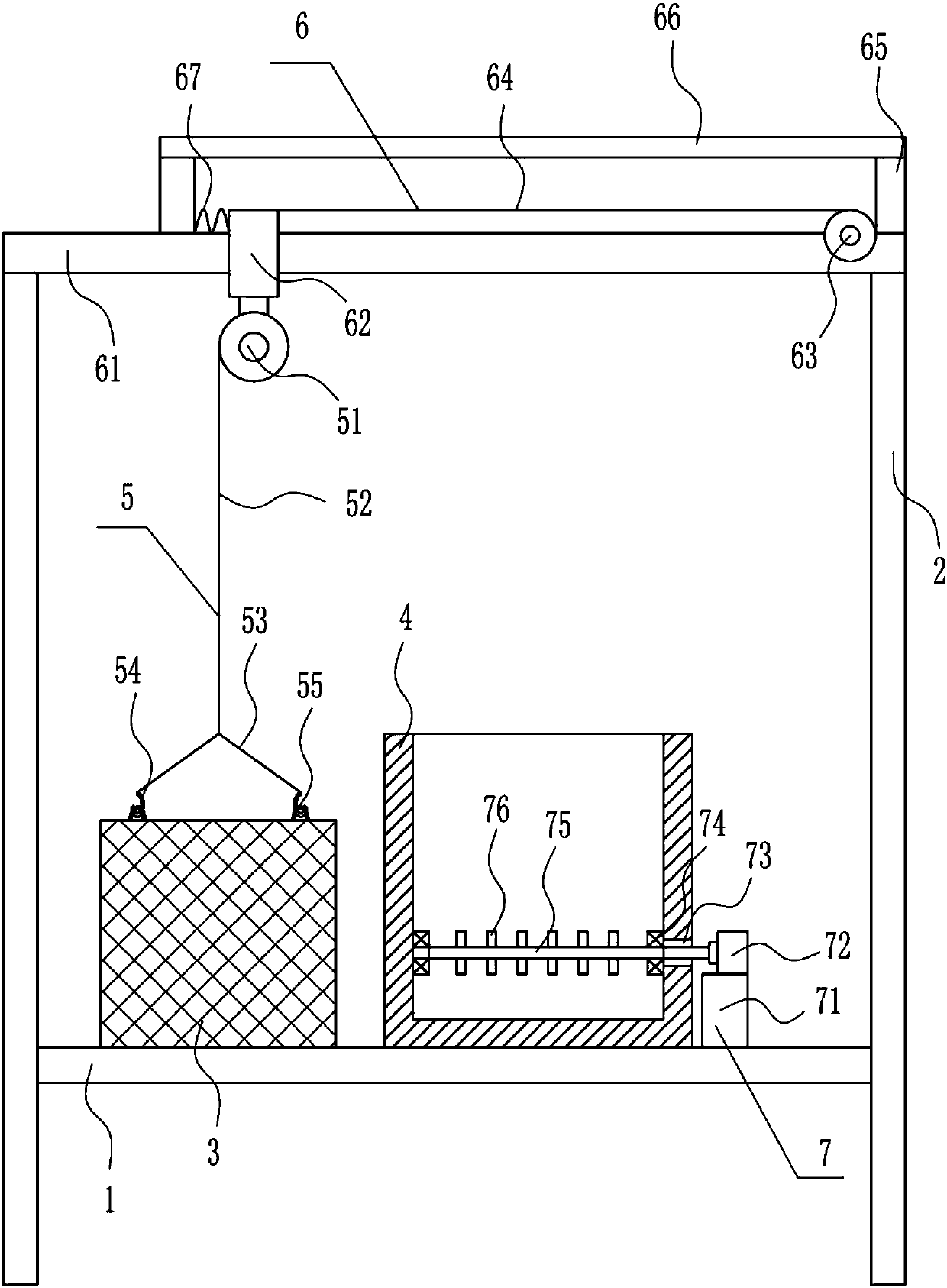

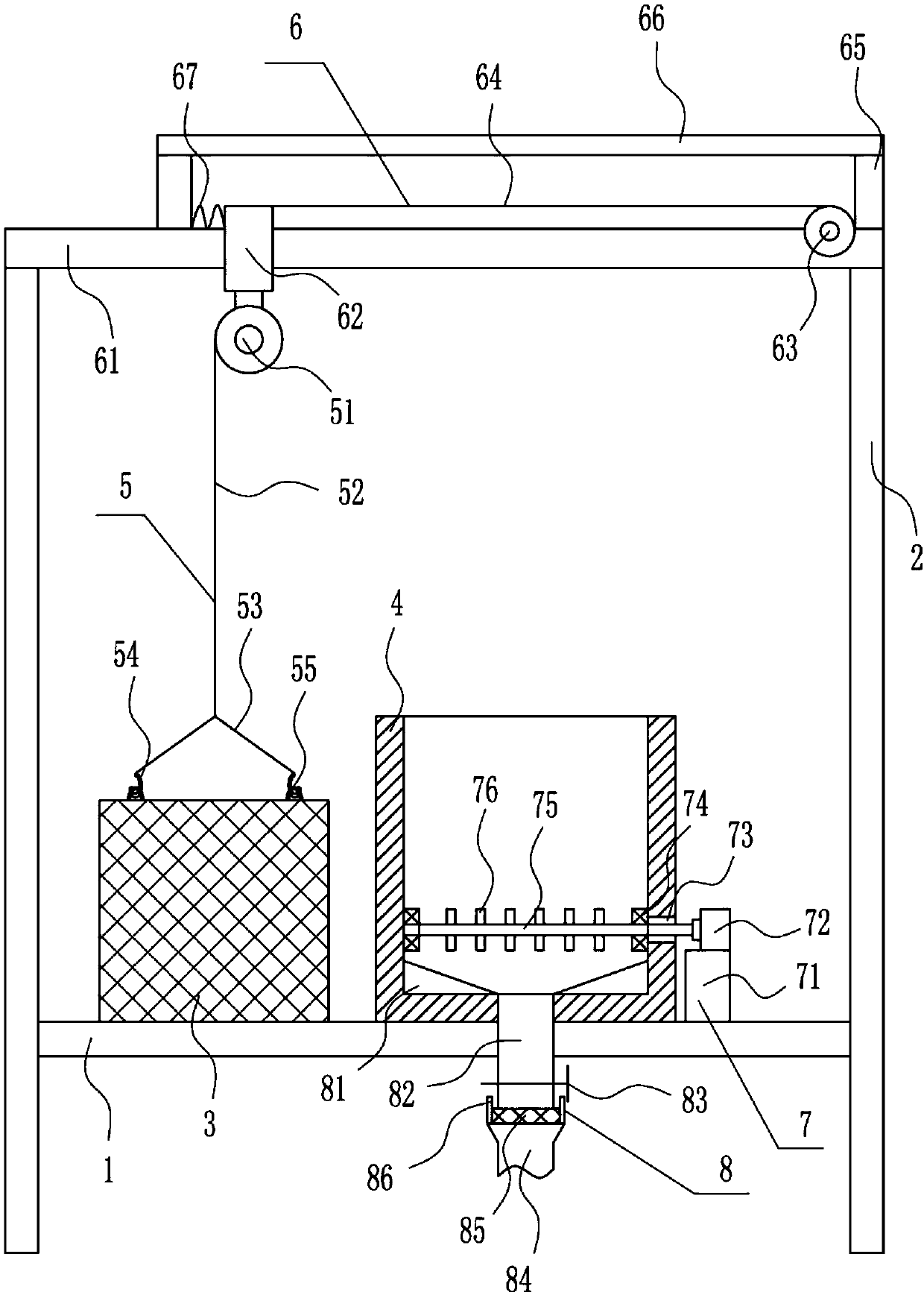

[0037] A kind of derusting device for spring, such as Figure 1-5 As shown, it includes a horizontal plate 1, a support plate 2, a screen frame 3, a frame body 4, a hoisting device 5 and a moving device 6, and the left side and the right side of the horizontal plate 1 are equipped with a support plate 2. A moving device 6 is arranged between the tops of the boards 2, a lifting device 5 is arranged on the moving part of the moving device 6, a screen frame 3 is arranged on the left side of the top of the horizontal board 1, the top of the screen frame 3 is connected with the lifting device 5, and the top of the horizontal board 1 is connected to the lifting device 5. Frame body 4 is installed on the right side.

[0038] Lifting device 5 comprises first electric reel 51, first backguy 52, branch wire 53, hook 54 and hanging ring 55, is connected with first electric reel 51 on the mobile part of moving device 6, and first electric reel The first backguy 52 is wound on the wire wh...

Embodiment 3

[0040] A kind of derusting device for spring, such as Figure 1-5 As shown, it includes a horizontal plate 1, a support plate 2, a screen frame 3, a frame body 4, a hoisting device 5 and a moving device 6, and the left side and the right side of the horizontal plate 1 are equipped with a support plate 2. A moving device 6 is arranged between the tops of the boards 2, a lifting device 5 is arranged on the moving part of the moving device 6, a screen frame 3 is arranged on the left side of the top of the horizontal board 1, the top of the screen frame 3 is connected with the lifting device 5, and the top of the horizontal board 1 is connected to the lifting device 5. Frame body 4 is installed on the right side.

[0041] Lifting device 5 comprises first electric reel 51, first backguy 52, branch wire 53, hook 54 and hanging ring 55, is connected with first electric reel 51 on the mobile part of moving device 6, and first electric reel The first backguy 52 is wound on the wire wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com