Large-span multi-braced-arched-rib vertical rotation construction method

A construction method and a large-span technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of uncontrollable lifting synchronization of two slings, affecting the construction safety of the entire arch rib vertical rotation, etc., to improve stability safety and security, maintain safety and efficiency, and achieve precisely tuned effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

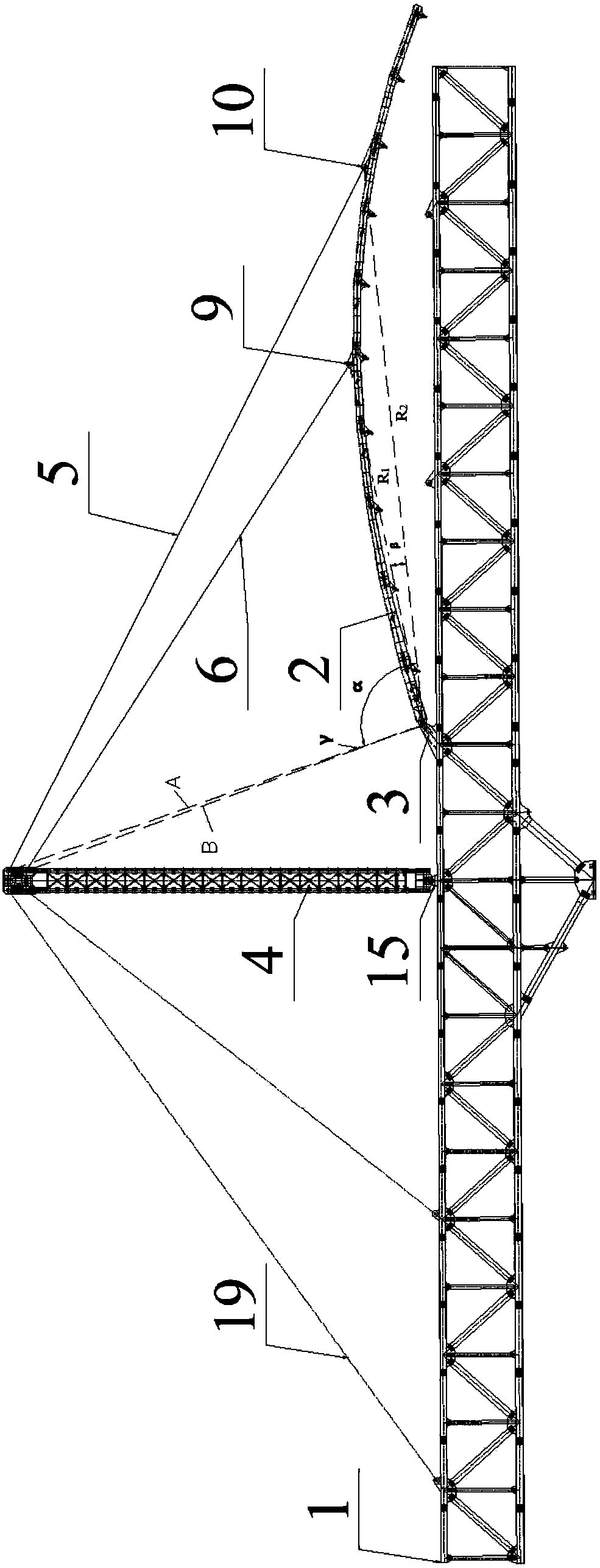

[0060] Such as figure 1 As shown, it is a schematic diagram of the arrangement structure of the present invention. The half arch rib 2 is assembled on the rigid beam 1, and the support frame 11 is used to support the half arch rib 2 below. The support frame 11 is provided with a jack for adjusting the height of the half arch rib 2. Position, the lower end of the half arch rib 2 is connected with the hinge 3 on the rigid beam 1, the lower end of the half arch rib 2 of the present embodiment refers to the end near the side of the buckle tower 4 corresponding to it, and the upper end is away from the corresponding The end of the gusset side.

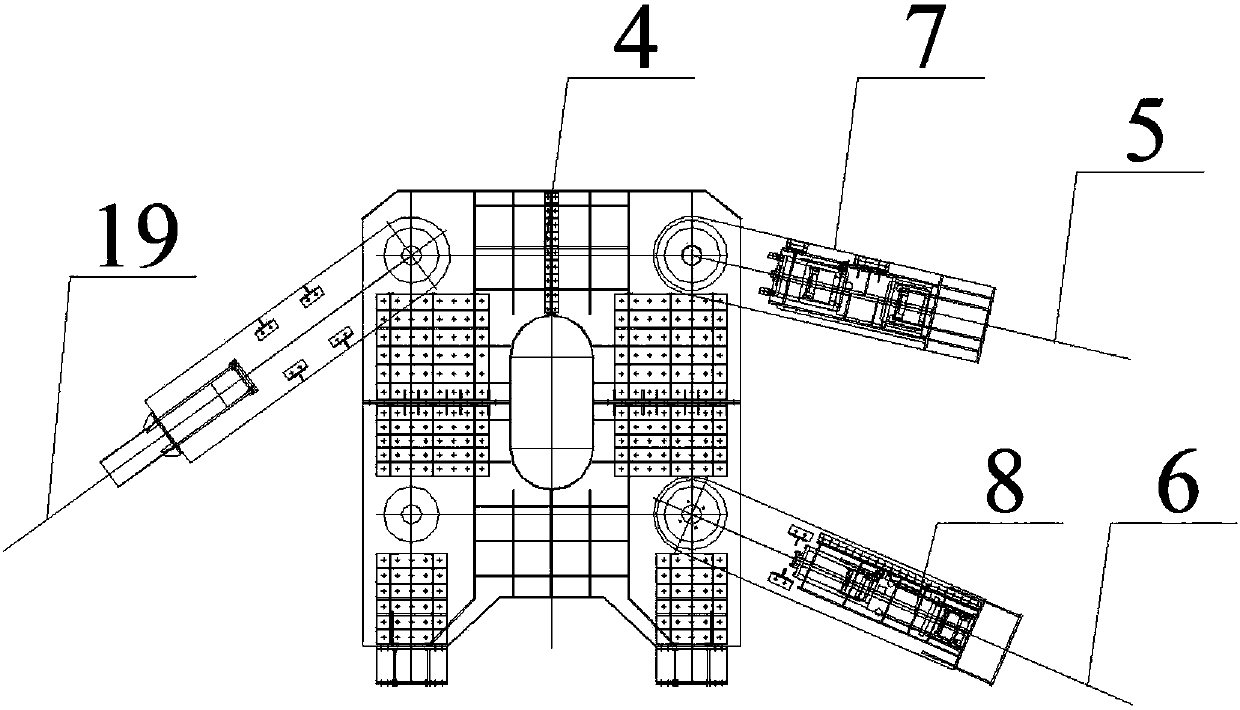

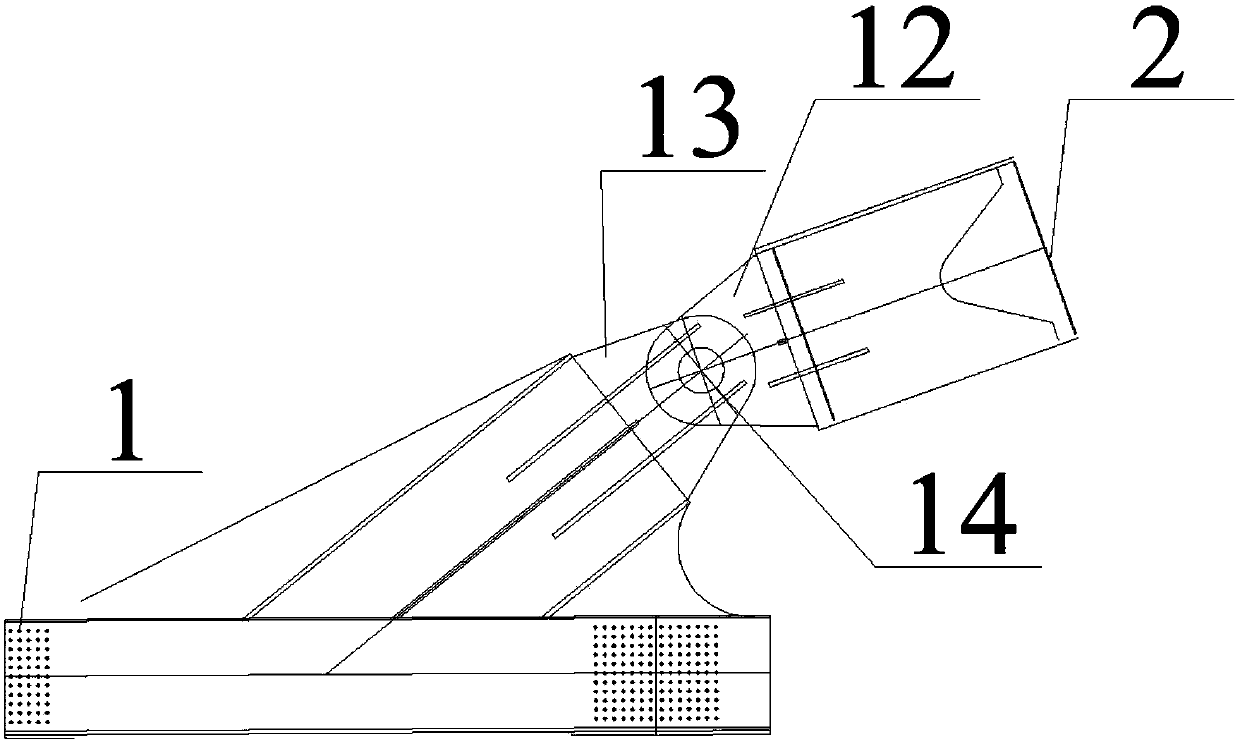

[0061] Such as image 3 As shown, the hinge support 15 is installed on the rigid beam 1, and the buckle tower 4 is lifted to the top of the hinge support 15, so that the second support plate 16 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com