Advance digging hydraulic cleaving machine for mine blasting

A splitting machine and hydraulic technology, applied in open-pit mine mining, discharge machinery, special mining, etc., can solve the problems of staff discomfort, staff injury, inconvenient operation, etc., to achieve convenient use, avoid injury, and firm connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] as attached figure 1 to attach Figure 8 Shown:

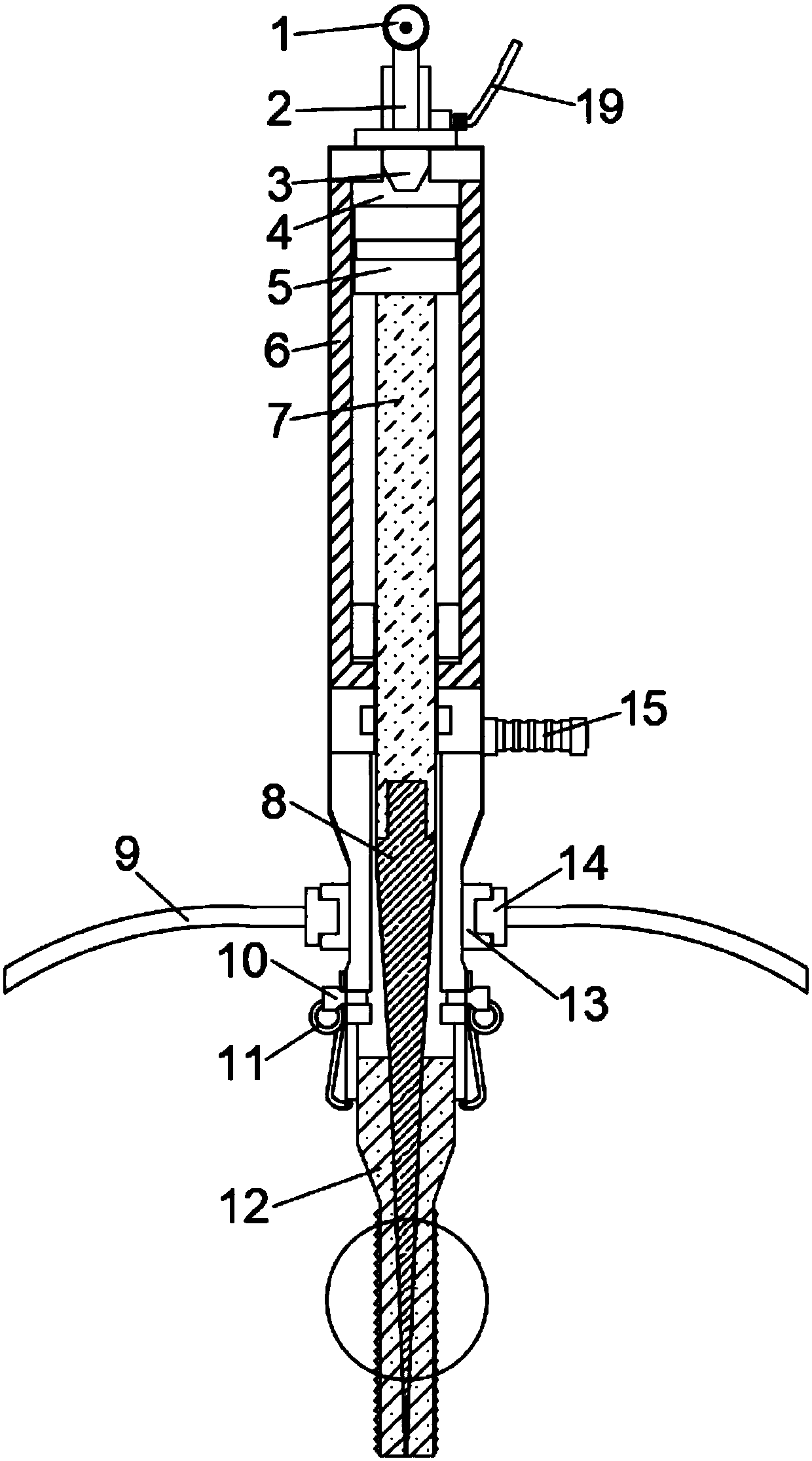

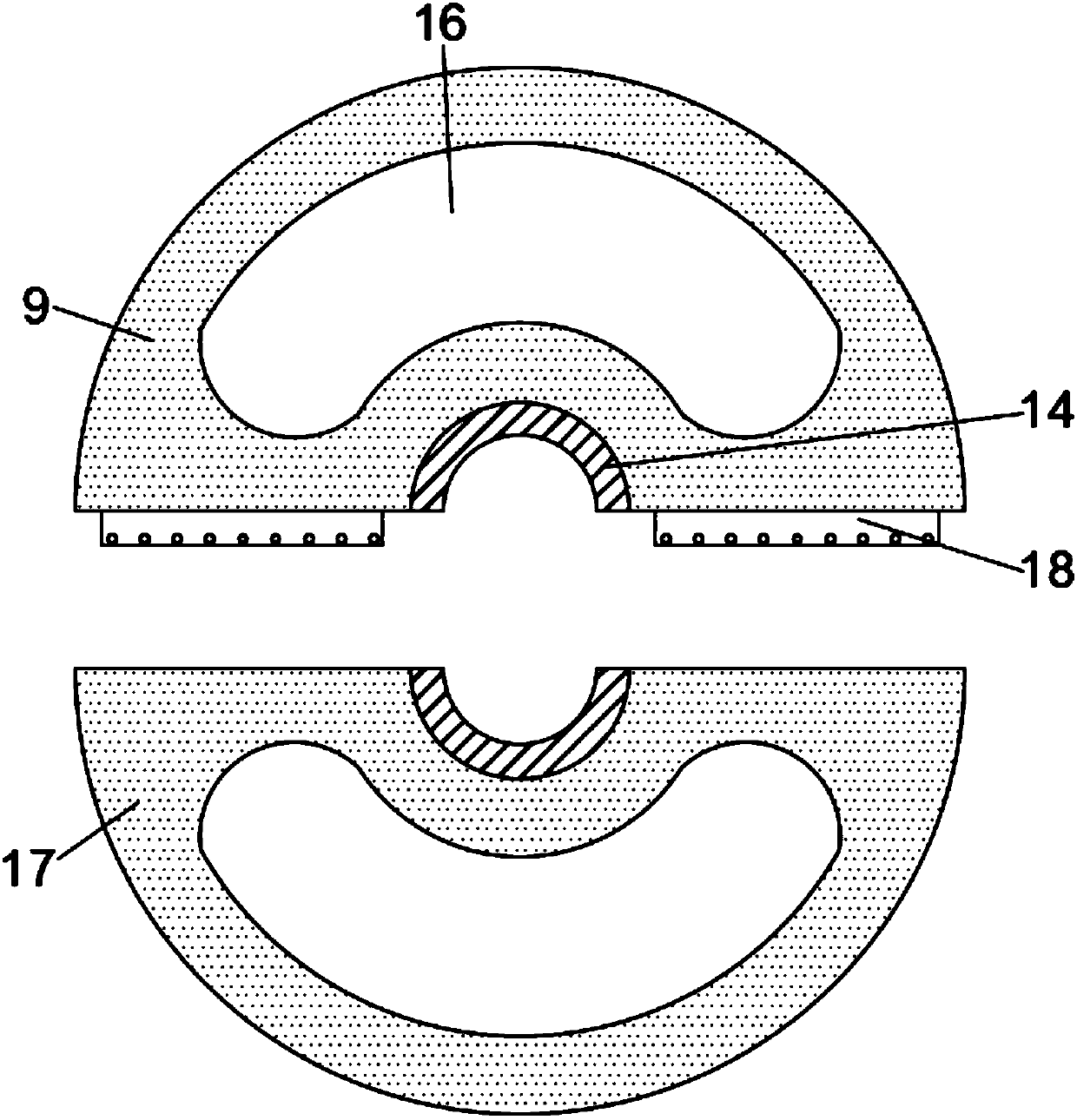

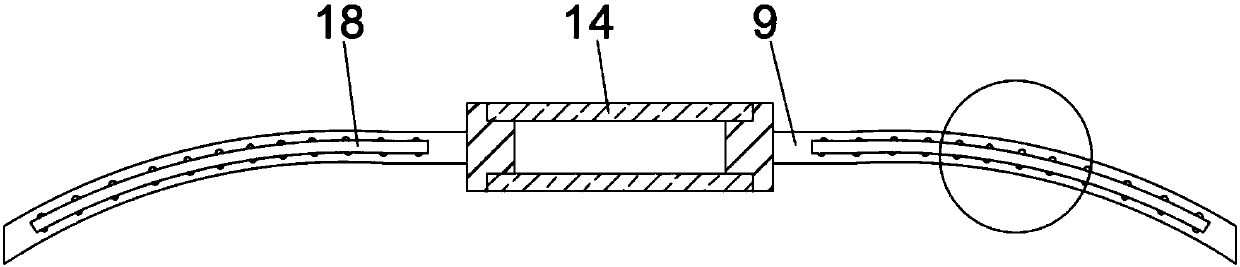

[0031] The invention provides a pre-excavation hydraulic splitter for mine blasting, which includes a main handle 1, a handle connecting rod 2, an oil inlet nozzle 3, a hydraulic oil chamber 4, a piston 5, a main body shell 6, a piston rod 7, Top block 8, No. 1 protective baffle 9, spring fixing screw 10, spring 11, splitting block 12, magnetic baffle holder 13, magnetic baffle block 14, auxiliary grip 15, tempered glass window 16, two No. 1 protective baffle 17, No. 1 protective baffle bump 18 and hydraulic pipe 19;

[0032] The top of the main body shell 6 is fixedly installed with a main handle 1 through the handle connecting rod 2; the top of the main body shell 6 is also embedded with an oil inlet nozzle 3, and a hydraulic pipe 19 is fixedly installed on the top side of the oil inlet nozzle 3; A hydraulic oil chamber 4 is fixedly arranged on the inner side of the top of the main body casing 6; a piston 5 is arran...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap