Device for testing slump of concrete mixture and use method thereof

A test device and concrete technology, applied in the field of concrete, can solve problems such as large errors, test stability and accuracy need to be improved, and achieve the effects of simple and effective structure, avoiding errors, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

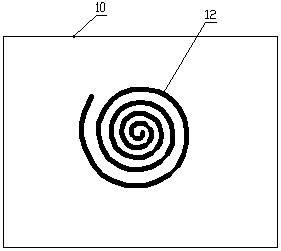

Image

Examples

Embodiment Construction

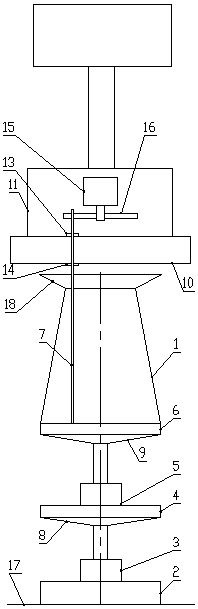

[0024] like figure 1 and figure 2 As shown, the inventive concrete mixture slump test device comprises a lower electric push rod mechanism, a middle electric push rod mechanism, an upper electric push rod mechanism, a slump cylinder 1 and a screw motion mechanism;

[0025] The lower electric push rod mechanism includes a lower base 2 arranged on the ground, and the lower base 2 is provided with a lower electric push rod 3; the middle electric push rod mechanism includes a middle base 4, and the middle base 4 is provided with a middle electric push rod 5; The top of the protruding rod of the push rod 3 is connected to the lower surface of the middle base 4; the protruding rod of the middle electric push rod 5 is connected upward to the upper base 6, and the slump cylinder 1 is connected to the upper base 6;

[0026] The upper electric push rod is located directly above the slump cylinder 1 and its extension rod is vertically connected downwards to the screw movement mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com