Lifting device for drug lump machine

The technology of a lifting device and a dosing machine is applied in the directions of mixers, mixer accessories, transportation and packaging, etc. It can solve the problems of incomplete discharge, material waste, safety hazards, etc., to improve work efficiency, avoid safety hazards, and quickly Effective discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and the environment in which it is applied.

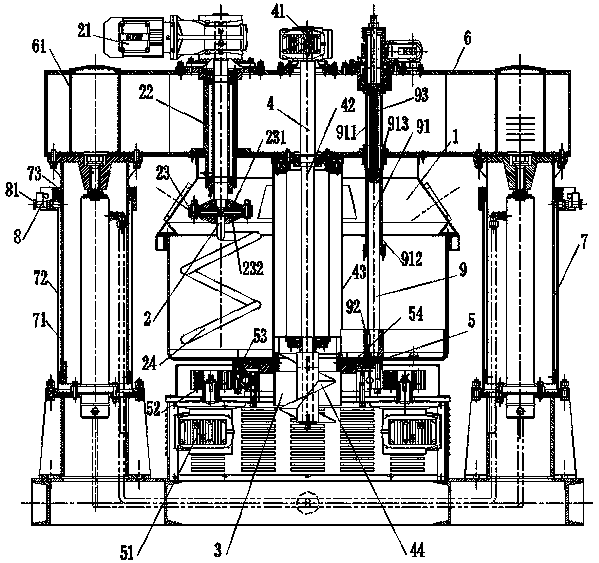

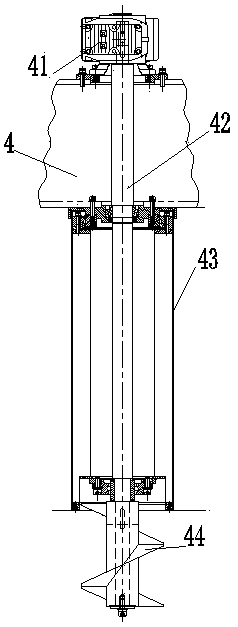

[0024] The lump machine includes a rotatable mixing pot 1, which is provided with a turning and mixing device 2 and a bottom discharge device 3, and the bottom discharge device 3 is composed of a central lifting device that can move up and down. 4 Realize the closure of the bottom discharge device 3; the lower part of the mixing pot 1 is also provided with a turning device 5 for turning the mixing pot 1;

[0025] The mixing pot 1 is fixedly connected to the upper box body 6 through a connecting device.

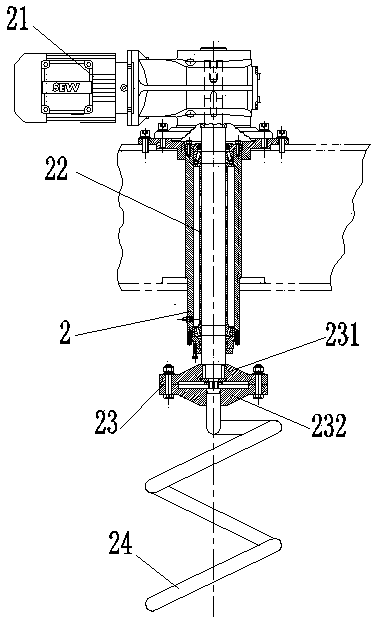

[0026] The turning and mixing device 2 includes a drive motor one 21, and a turning and mixing shaft 22 driven by the driving motor 21 to rotate. The connecting flange 23 is formed by connecting two correspondingly arranged upper flanges 231 and lower flanges 232 , and the stirring paddles 24 are connected to the lower flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com