Cold iron, sand core designing method for conveniently storing cold iron and cold iron storing method

A design method and cold iron technology, applied in the direction of mold cores, casting molding equipment, metal processing equipment, etc., can solve the problems of difficult removal, high labor requirements, and difficult placement of forming cold iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Such as Figure 5 As shown, this embodiment provides a cold iron, which is composed of a plurality of steel shots 1, and a cylinder head on a diesel engine is taken as an example. figure 1 — Figure 4 As shown, this embodiment also provides a sand core design method that is convenient for placing cold iron, including the following steps:

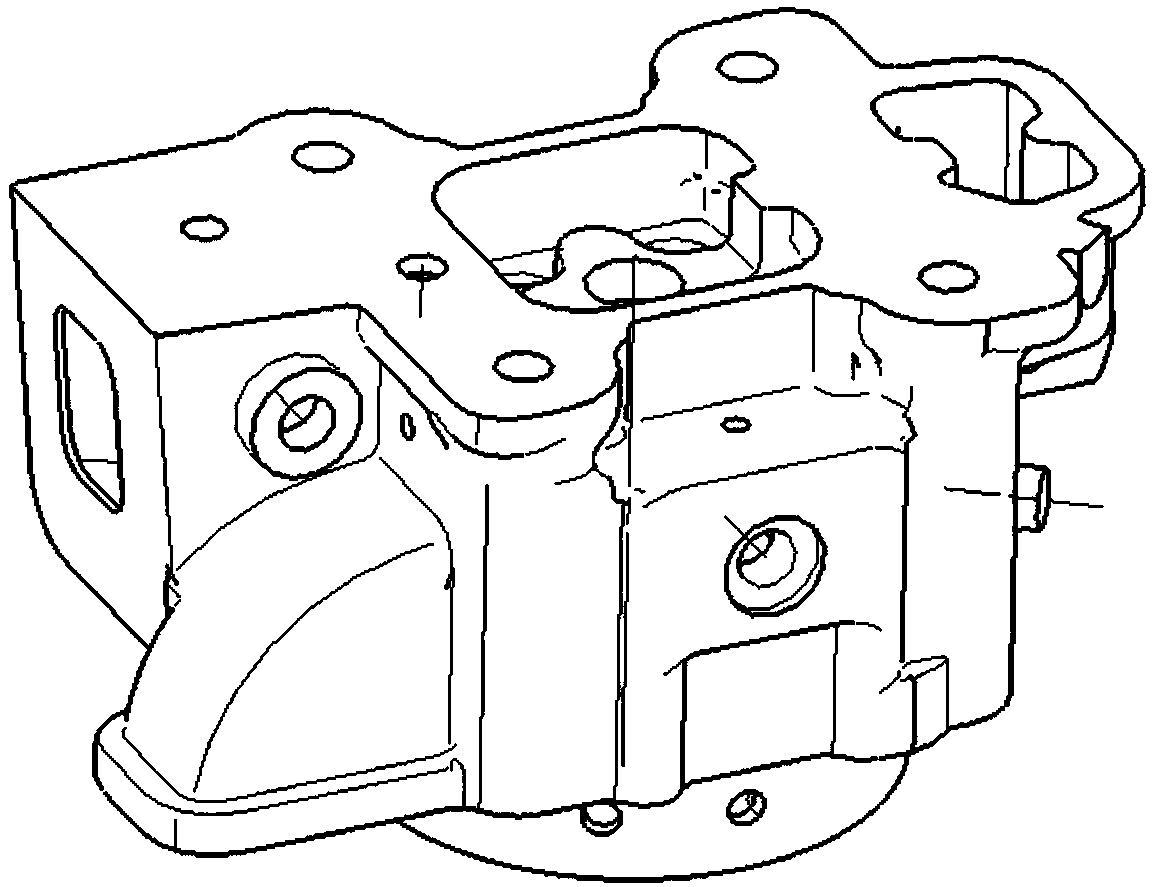

[0041] Step 1: Such as figure 1 As shown, 3D modeling software is used to build a 3D casting model according to the requirements of the 2D drawing of the casting;

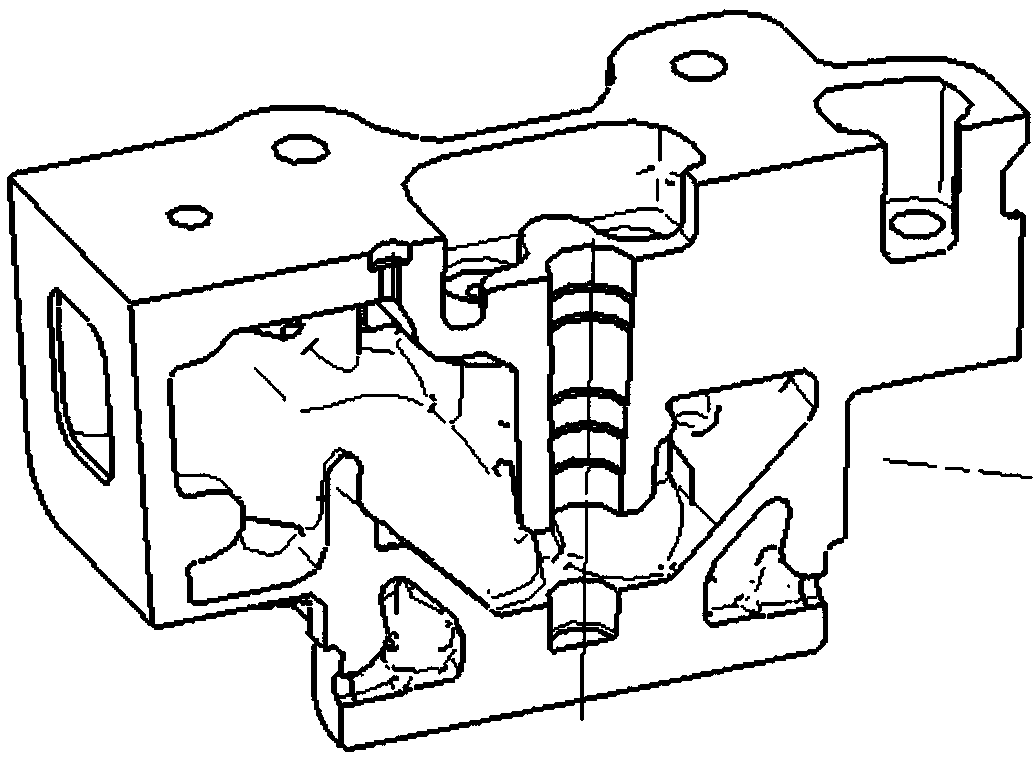

[0042] Step 2: Such as figure 2 As shown, the 3D casting process model of the casting is designed with 3D modeling software according to the 3D casting model in step 1;

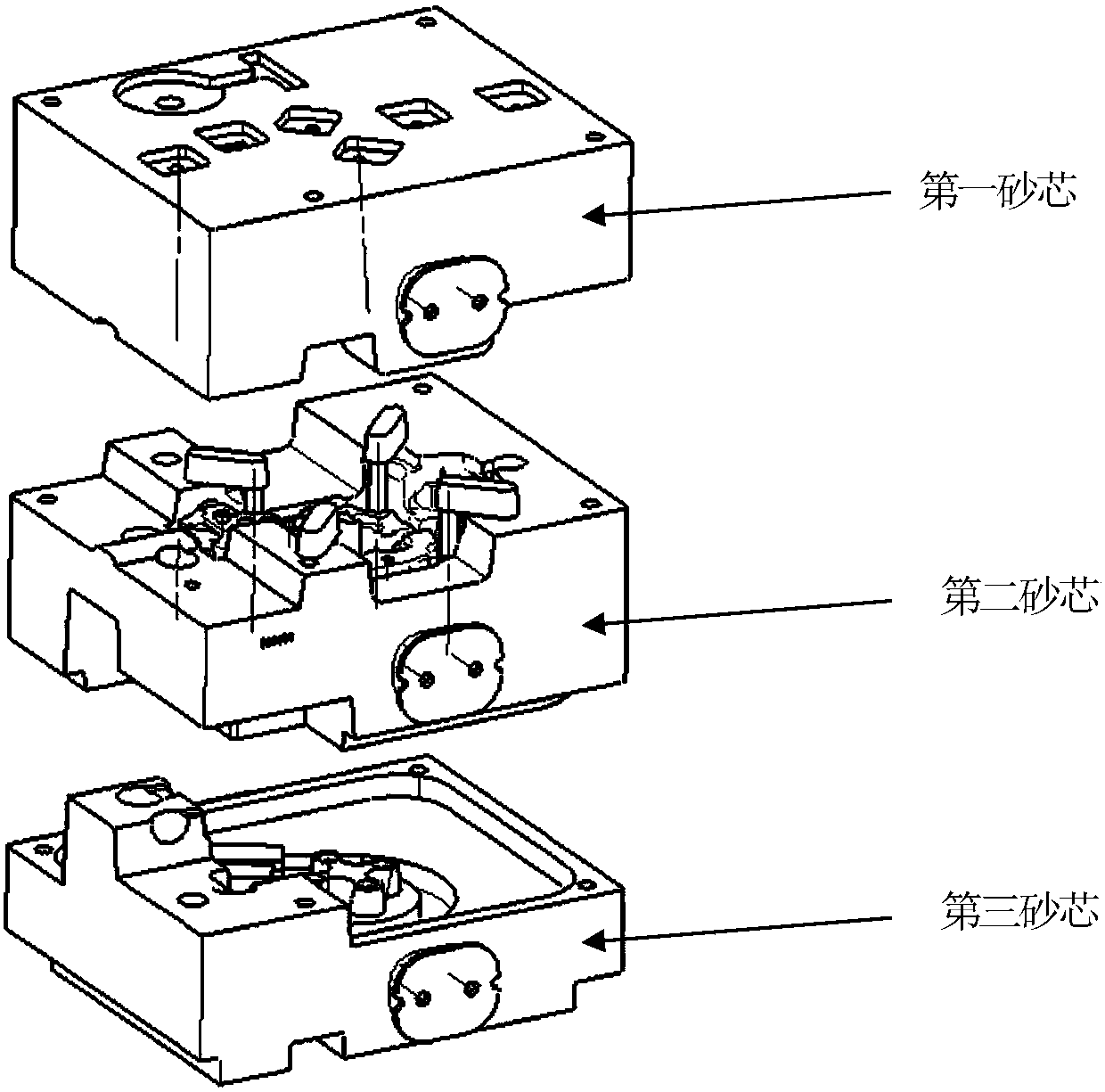

[0043] Step 3: Design a 3D sand core model with 3D modeling software according to the 3D casting process model in step 2;

[0044] Step 4: Such as Figure 4 As shown, the steel shot sand landfill space is set in the three-dimensional sand core model;

[0045] Step 5: 3D print the sand core according to the 3D sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com