A fat large transport ship with a raised bilge

A transport ship and bilge technology, applied in the field of fat transport ships, can solve the problems of reducing energy consumption requirements of ballast water treatment devices, energy saving and emission reduction, disadvantages, etc., and achieves small square coefficient, reduced fuel consumption, and local structure optimization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

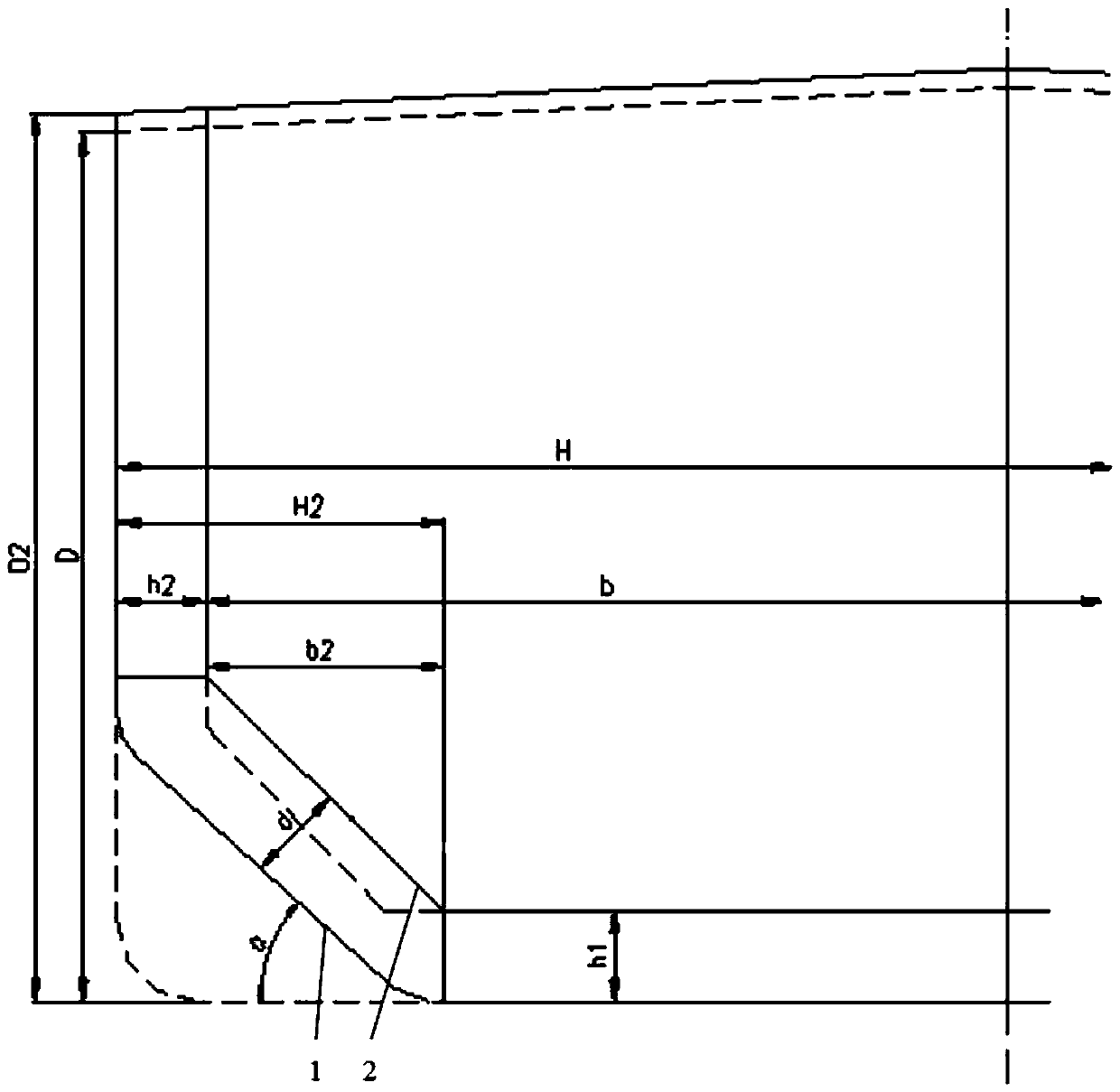

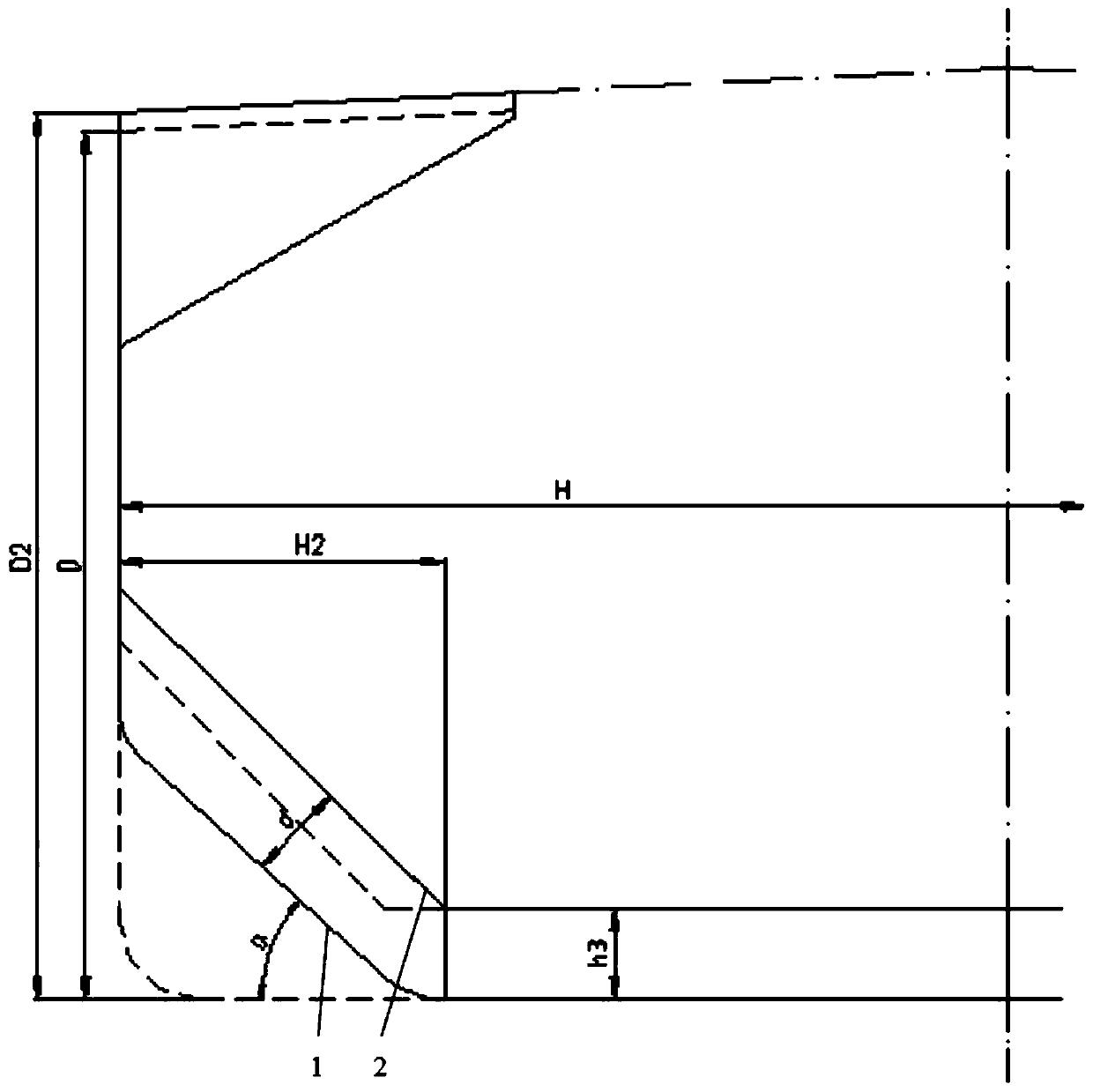

[0022] figure 1 It is a schematic diagram of a double-sided fat transport ship with raised bilge of the present invention, figure 2 It is a schematic diagram of a single-side side bulk carrier of a hypertrophy carrier with raised bilge of the present invention, please refer to figure 1 , figure 2 As shown, a hypertrophy transport ship with a raised bilge of a preferred embodiment is shown, including an inclined straight bilge outer plate 1 and a hopper knuckle 2 . The relationship between the distance between the hopper tank knuckle 2 and the side shell plating of the transport ship and the width of the transport ship satisfies: H2=0.33H±5%, where H2 is the hopper tank knuckle 2 and the side shell of the transport ship The distance between the boards, H is the width of the transport ship. The relationship between the distance between the hopper knuckle 2 and the inner hull of the transport ship and the width of the cargo hold of the transport ship satisfies: b2=0.28b±5%, ...

no. 2 example

[0029] Please continue to see figure 1 As shown, a double-side skin hypertrophy transport ship is shown, which includes an oblique straight bilge shell plate 1 and a hopper knuckle 2 . The angle α between the inclined straight bilge shell plate 1 and the bottom of the ship is 42°.

[0030] In addition, as a preferred embodiment, the h1=2450mm, h2=2400mm of the double-side skin hypertrophy transport ship, the average value of d is taken as 2655mm, wherein h1 is the inner bottom height of the double-side skin hypertrophy transport ship, h2 is the double-side skin breadth of double-side skin hypertrophy transport ship, and d is the distance from hopper tank knuckle 2 to inclined straight bilge shell plating 1.

[0031] Further, as a preferred embodiment, the H=24m of the double-side skin hypertrophy transport ship, H2=7.92m, wherein, H is the width of the double-side skin hypertrophy transport ship, H2 is the hopper knuckle 2 and The distance between the side shell plating of a...

no. 3 example

[0037] Please continue to see figure 1 As shown, a single-side skin bulk carrier is shown, which includes an inclined straight bilge shell plate 1 and a hopper tank knuckle 2 . The angle α between the inclined straight bilge shell plate 1 and the bottom of the ship is 42°.

[0038] In addition, as a preferred embodiment, the single-side skin bulk carrier of the single-side skin bulk carrier h1=2450mm, and the average value of d is 2655mm, where h1 is the inner bottom height of the single-side skin bulk carrier, d It is the distance from hopper tank knuckle 2 to inclined straight bilge shell plating 1.

[0039] Further, as a preferred embodiment, H=24m and H2=7.92m of the single-side skin bulk carrier, wherein, H is the width of the single-side skin bulk carrier, and H2 is the hopper tank knuckle 2 and single-side skin The distance between side shell plating of bulk carriers.

[0040] On the other hand, as a preferred embodiment, in order to make up for the loss of the cargo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com