Robot clamp with clamping and material sucking functions

A robotic fixture and clamping mechanism technology, applied in the direction of chucks, manipulators, manufacturing tools, etc., can solve the problems of reducing product qualification rate, increasing labor costs, easy to scratch, etc., to improve the degree of automation, reduce labor costs, avoid The effect of scratches on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

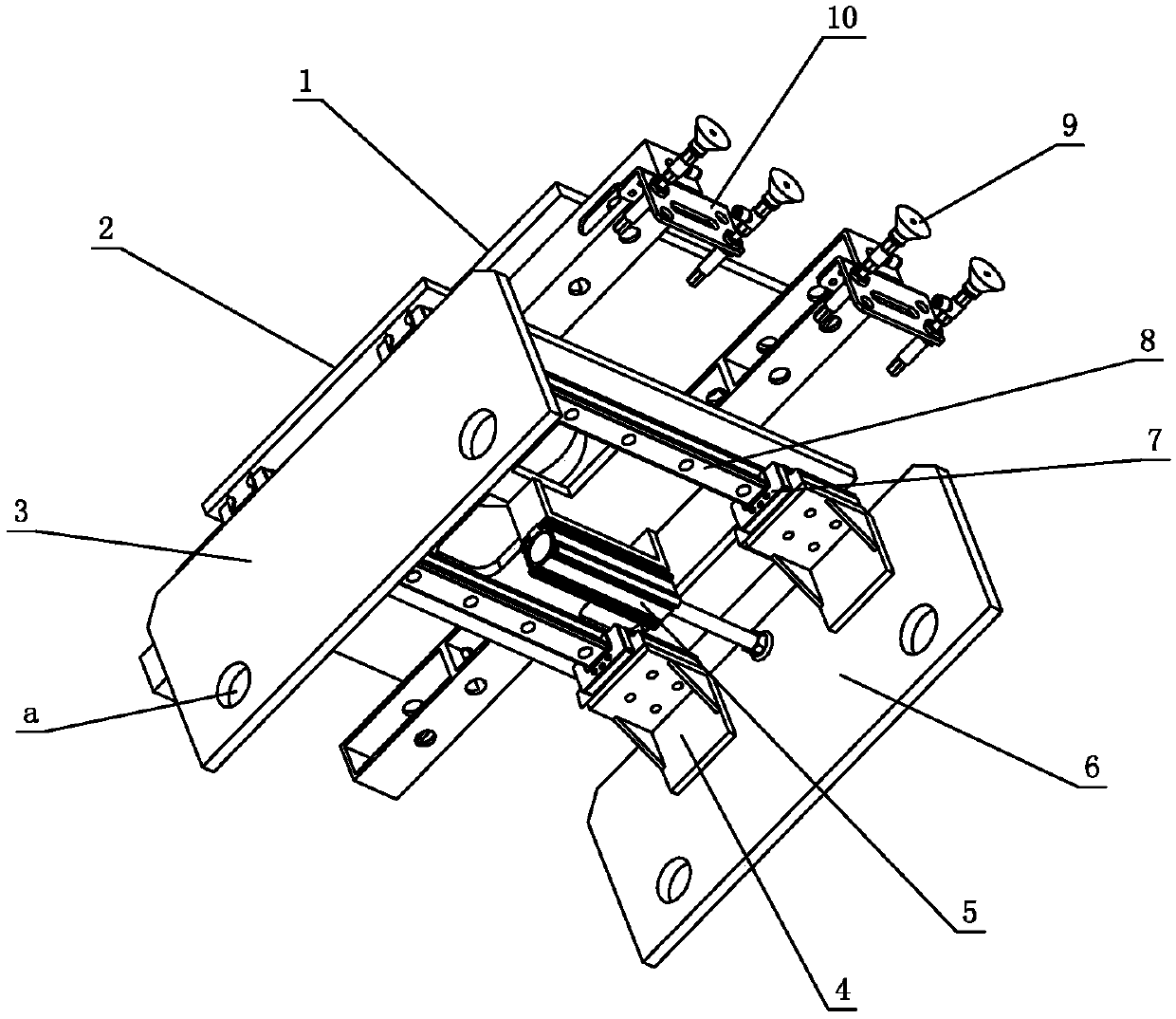

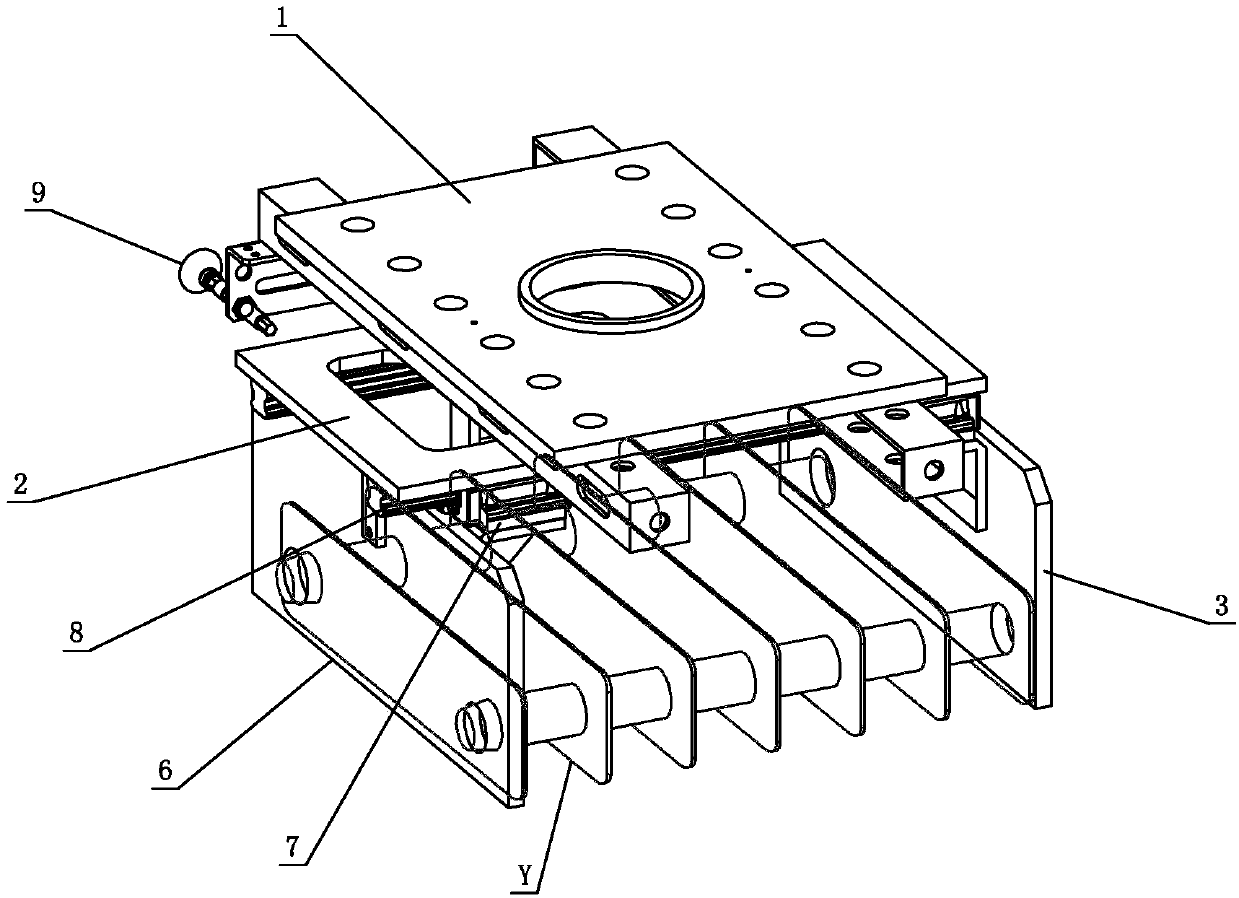

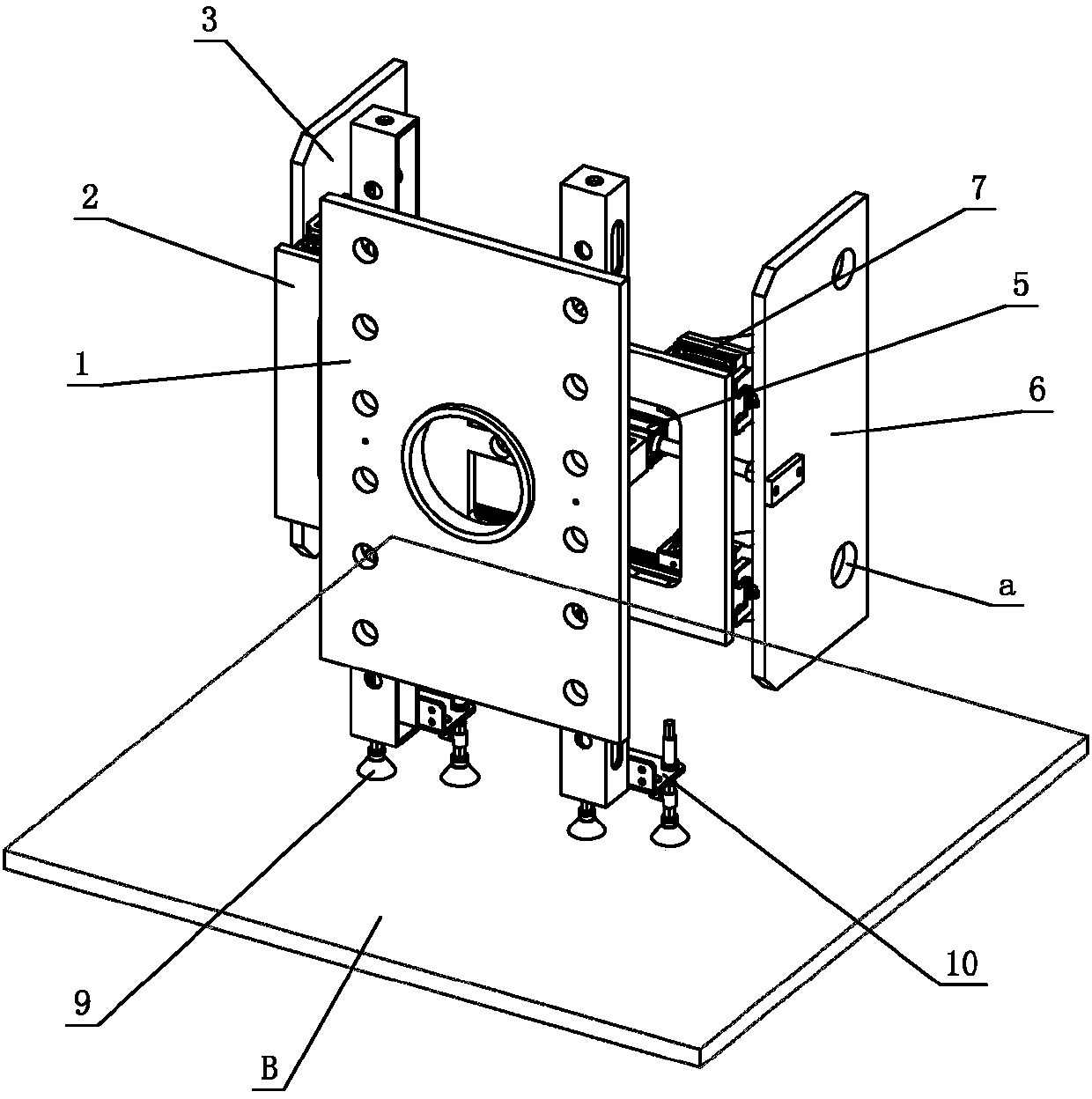

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, taking the palletizing work of oily resin Y as an example.

[0020] see Figure 1-Figure 6 , the robot fixture with clamping and suction functions is used to clamp the oil group composed of several oils Y. The robot fixture includes a fixture bracket connected to the robot through a flange. The fixture bracket is provided with a clamping mechanism and Suction mechanism; wherein, the clamping mechanism includes a first clamping plate 3, a second clamping plate 6 and a clamping drive assembly respectively arranged on the clamp bracket, and the clamping drive assembly drives the second clamping plate 6 relative to the clamp bracket Sliding back and forth to make the two clamping plates close to or far away from each other to achieve the effect of clamping the oil base Y. Since the two sides of the oil base Y are provided with convex points Y1, the first clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com