Diaphragm valve as well as fluid conveying equipment formed by diaphragm valve and conveying method thereof

A technology of fluid conveying and diaphragm valve, applied in the direction of diaphragm valve, diaphragm, mechanical equipment, etc., can solve the problems of high cost, high failure rate, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

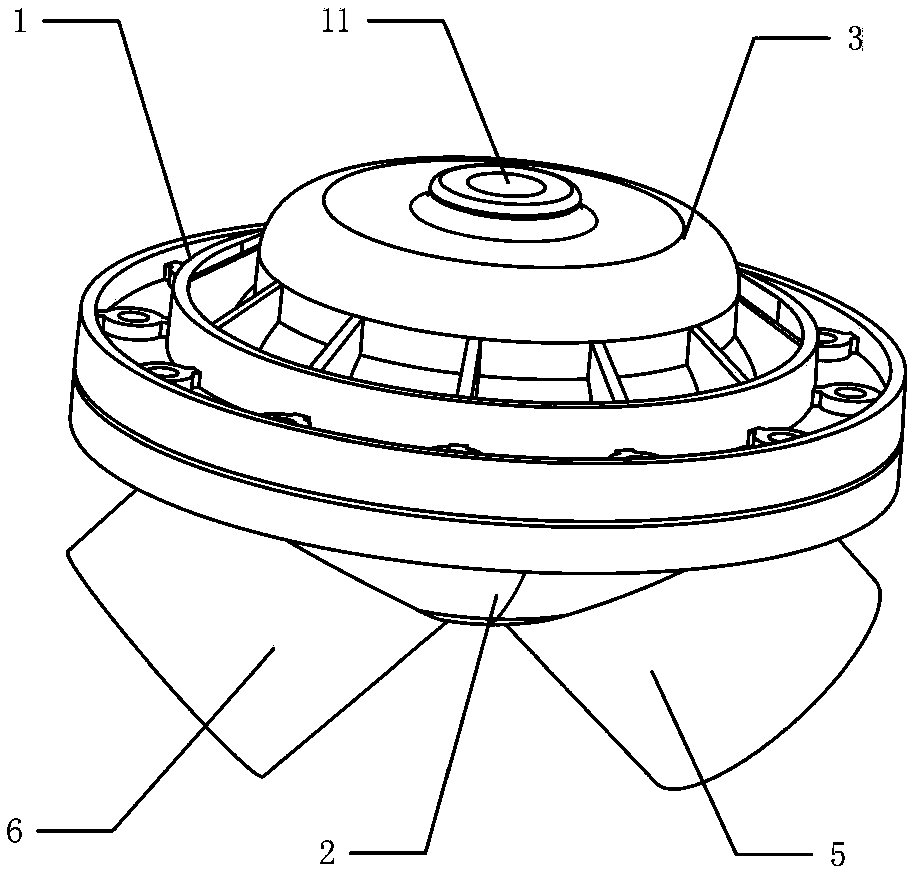

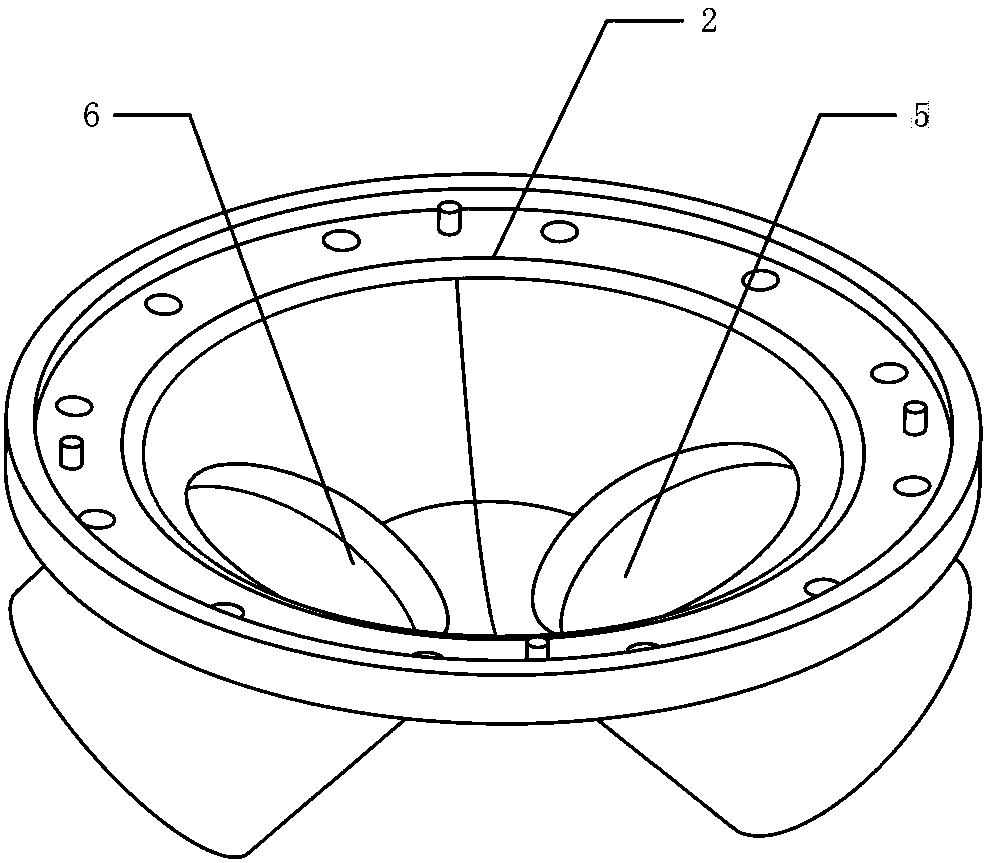

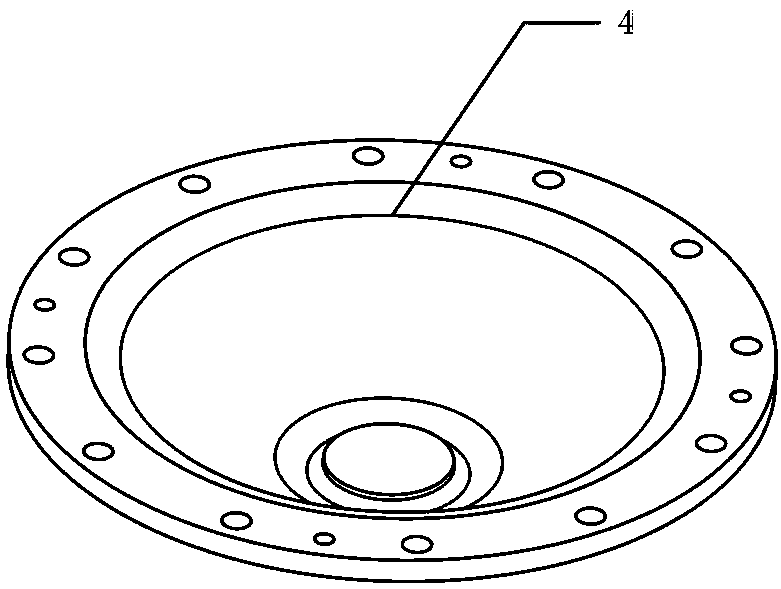

[0046] The first embodiment: a fluid conveying device composed of one diaphragm valve.

[0047] Such as Figure 5 , 6 As shown, the valve body inlet 5 is connected to the toilet, and the valve body outlet 6 is connected to the vacuum sewage tank.

[0048] The valve cover 3 is connected to the vacuum dirt collection tank through the electromagnetic valve 7, that is, the first passage 8 of the electromagnetic valve is connected to the valve cover 3, and the second passage 9 of the electromagnetic valve is connected to the second passage 9 of the electromagnetic valve. The third channel 10 communicates with the atmosphere and the vacuum collection tank respectively.

[0049]The fluid conveying equipment is divided into three working states:

[0050] (1) In the case of no need to transport fluid, the solenoid valve 7 is not energized, such as Figure 5 Said, the position of the electromagnetic valve slider 12 is at A, the negative pressure cannot enter the inner cavity of the ...

no. 2 example

[0053] The second embodiment: a fluid conveying device composed of two diaphragm valves.

[0054] Such as Figure 7 As shown, the valve body inlet 5 is connected to the valve body outlet 6', that is, the two diaphragm valves are connected together. In this way, if solid residues are deposited on the bottom of the individual diaphragm valves, causing the diaphragms to not seal the inlet and outlet of the valve body tightly, the diaphragm valves as a whole can still achieve good opening and closing effects.

[0055] The fluid conveying equipment is divided into three working states:

[0056] (1) In the case of no need to transport fluid, the solenoid valve 7 is not energized, such as Figure 5 Said, the position of the electromagnetic valve slider 12 is at A, the negative pressure cannot enter the inner cavity of the diaphragm valve 1 and the diaphragm valve 1', the inner cavity of the valve is connected with the atmosphere, and the inner cavity of the valve is in a normal pre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap