A dust sensing device

A sensing device, dust technology, applied in the direction of measuring device, suspension and porous material analysis, particle suspension analysis, etc., can solve the problems of continuous monitoring of dust, limited number of measurements, short working time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

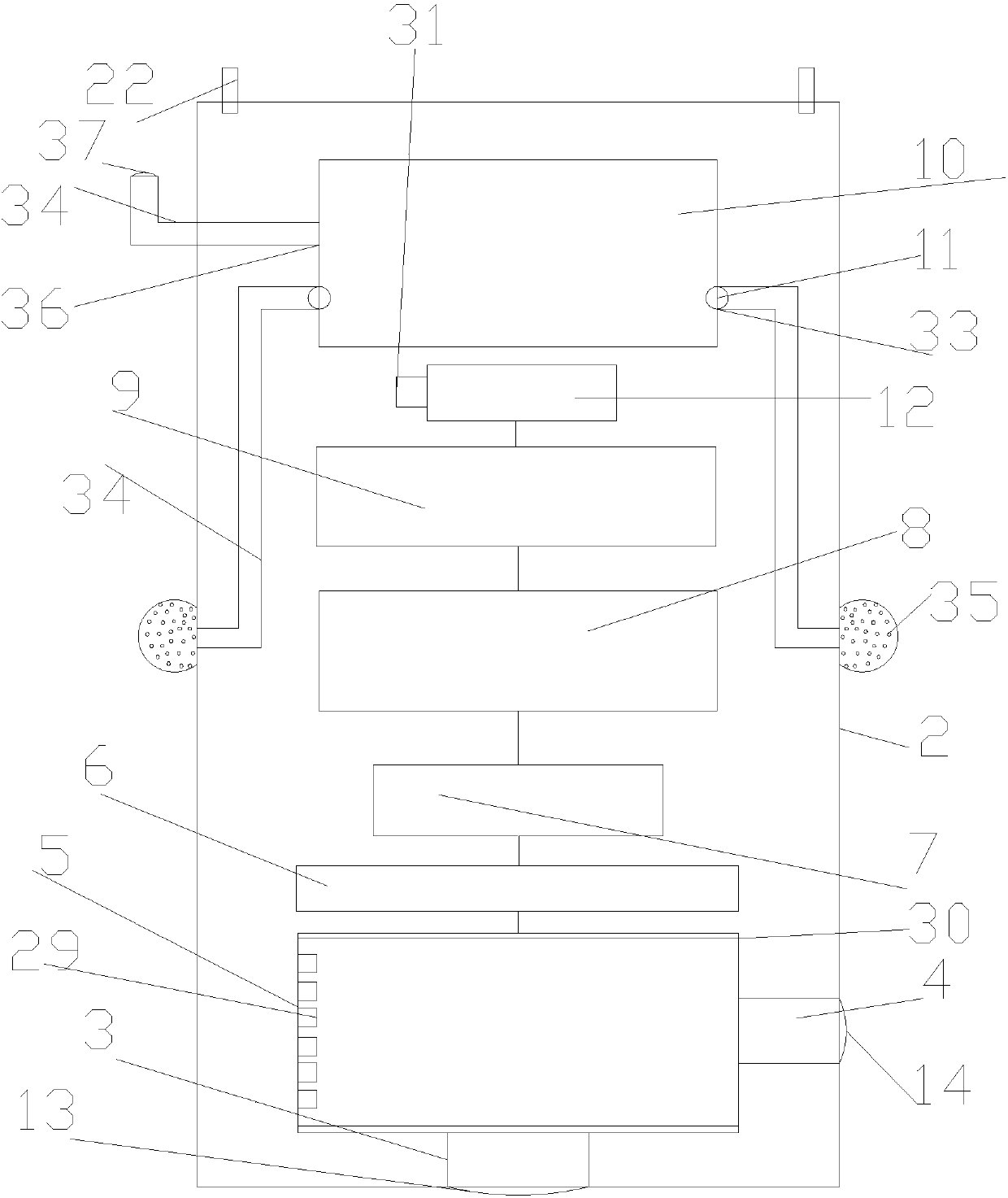

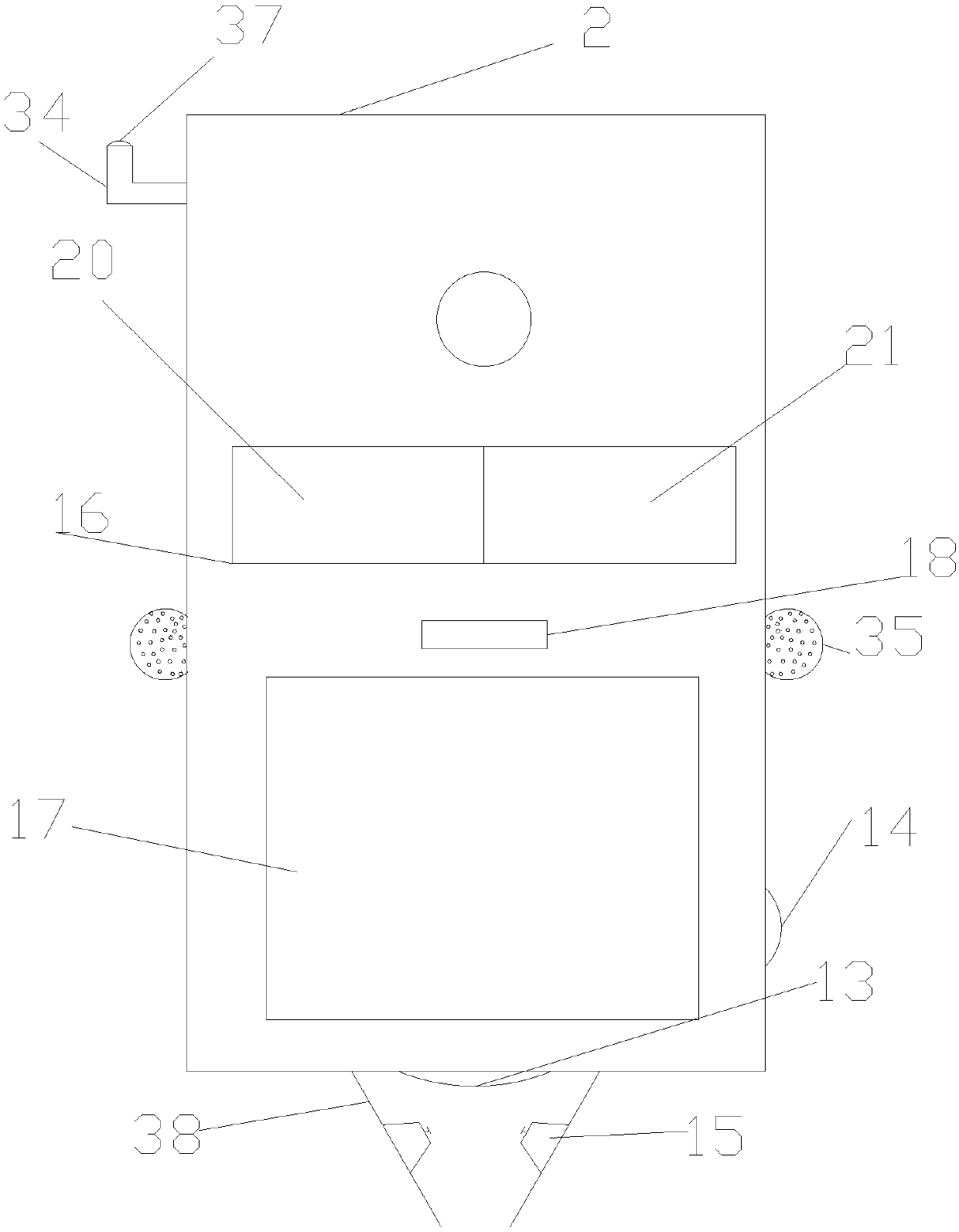

[0024] Embodiment 1 refers to Figure 1-4 , a dust sensing device, comprising a casing, the casing includes a casing cover 1 and a casing box 2, the casing cover 1 and the casing are used in cooperation, and the casing cover 1 is located at the top of the casing box 2 And it is used to close and open the casing box 2, the inside of the casing box 2 is in a cavity state, and the casing box 2 is provided with an air intake pipe 3, an exhaust pipe 4, a detector cassette, an A / D converter 6, a single chip microcomputer 7. Electric storage box 8, central processing unit 9, water tank 10, water pump 11 and alarm 12, air intake pipe 3 and exhaust pipe 4 are all cylindrical pipes, and its air intake pipe 3 is located at the bottom of the casing box 2, and the exhaust The air pipeline 4 is located on one side of the detector dark box 5, and the detector dark box, A / D converter 6, single-chip microcomputer 7, power storage box 8, central processing unit 9, water tank 10 and alarm 12 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com