Liquid-injection process of low-temperature lithium ion battery cell

A lithium-ion battery, low-temperature type technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of high melting point of EC, low performance of other batteries, high reduction potential, etc., to improve low-temperature performance, reduce internal air pressure, The effect of improving electrical performance and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

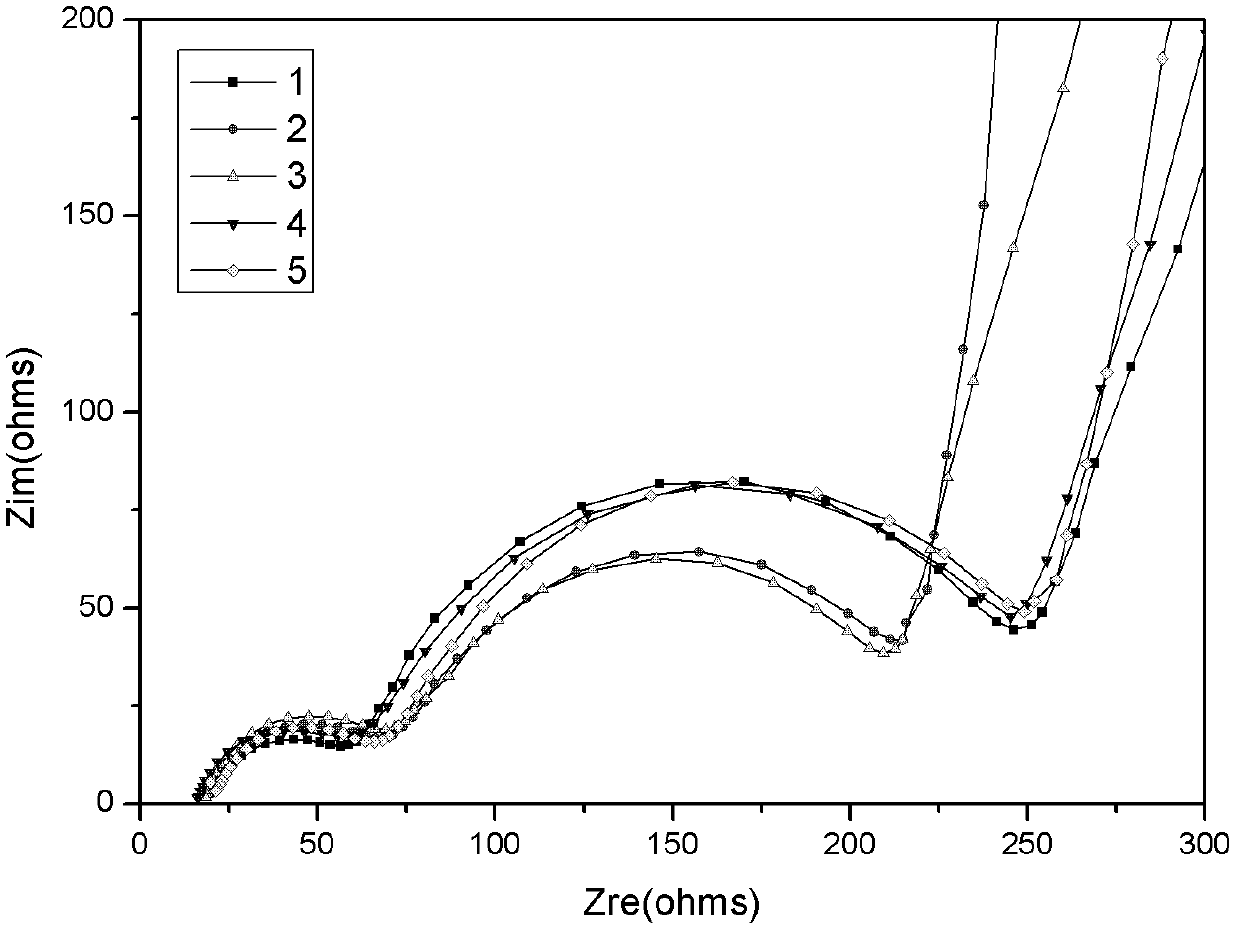

Embodiment 1

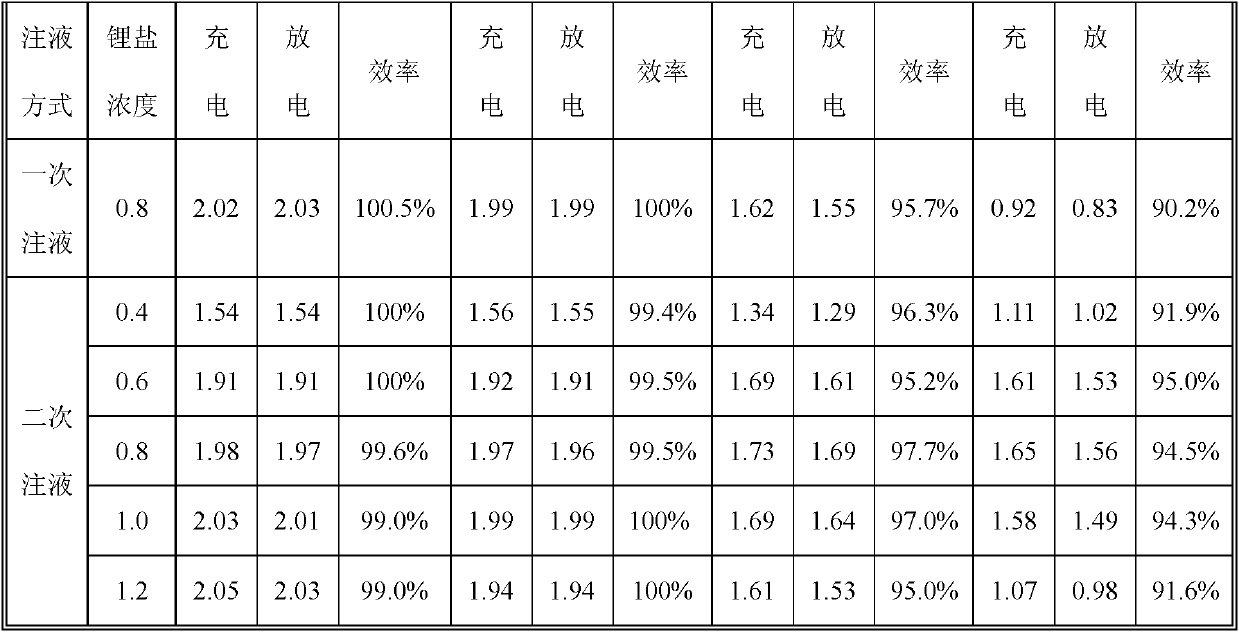

[0028] Use the same batch of 18650~2.0Ah lithium-ion battery cell electrode groups, 5 for each group, inject liquid into the cells, inject 70% of the total electrolyte solution (5.0g) required by the predetermined process requirements for the first time, and electrolyze The liquid composition is xM LiPF 6 (x=0.4, 0.6, 0.8, 1.0, 1.2)-EC / DMC / EMC (1:1:1, mass ratio), sealed, the battery is formed according to the traditional process after standing for 48 hours, 0.1C charge and discharge cycle several times to The charging and discharging efficiency reaches 100%. Then stand for 2min under vacuum (-0.5MPa), release the pressure, weigh, and then inject the electrolyte to form yM LiPF 6 (y is determined by x, so that the total concentration of lithium salt is 0.8M, such as when x=0.4, y=1.73)-PC / DEC / EMC (2:1:2, volume ratio), the remaining electrolyte, sealing, After standing for 48 hours, charge it to 4.2V with 0.5C, and then charge it at a constant voltage until the current decay...

Embodiment 2

[0034]Use the same batch of 18650~2.0Ah lithium-ion battery cell electrode groups, 5 for each group, inject liquid into the cells, inject 70% of the total electrolyte solution (5.0g) required by the predetermined process requirements for the first time, and electrolyze The liquid composition is 0.8MLiPF 6 -EC / DEC (1: 1, mass ratio), next step is the same as embodiment 1, then injects electrolyte composition and becomes 0.8M LiPF 6 -the surplus electrolyte of PC / EB (2: 8, volume ratio), all the other steps are with embodiment 1. Then test the charge-discharge capacity of the battery at 20°C, 0°C, -20°C, -40°C when the charge-discharge rate is 0.2C 6 -EC / DMC / EMC (1:1:1, mass ratio)

[0035] Electrolyte

[0036] The 1C charge and discharge capacity of the battery is compared, and the results are shown in Table 2. Table 2 is the comparison of charge and discharge capacity (Ah) and efficiency of batteries with different liquid injection processes in Example 2.

[0037] Table 2...

Embodiment 3

[0040] Use the same batch of 18650~2.0Ah lithium-ion battery cell electrode groups, 5 for each group, inject liquid into the cells, and inject 90% of the total electrolyte solution (5.0g) required by the predetermined process requirements for the first time, and electrolyze The liquid composition is 1.0M LiPF 6 -EC / DEC / DMC (1:1:1, mass ratio), the next steps are the same as in Example 1, and then inject the remaining amount of solvent PC, and the rest of the steps are the same as in Example 1. Then test the charge and discharge rate at 0.5C,

[0041] The charge and discharge capacity of the battery at 20°C, 0°C, -20°C, and -40°C is the same as that of a full-time injection of 1.0MLiPF 6 -Comparison of 1C charge and discharge capacity of batteries with EC / DEC / EMC (1:1:1, mass ratio) electrolyte, the results are shown in Table 3. Table 3 Comparison of charge and discharge capacity (Ah) and efficiency of batteries with different liquid injection processes in Example 3.

[0042...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com