Structural defect detection method for Czochralski monocrystalline silicon wafers

A technology of Czochralski single crystal and structural defects, which is applied in the direction of semiconductor/solid-state device testing/measurement, electrical components, circuits, etc., can solve problems such as cost waste, insufficient sensitivity, and complicated silicon wafer testing process, so as to avoid cost waste, Realize the effect of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

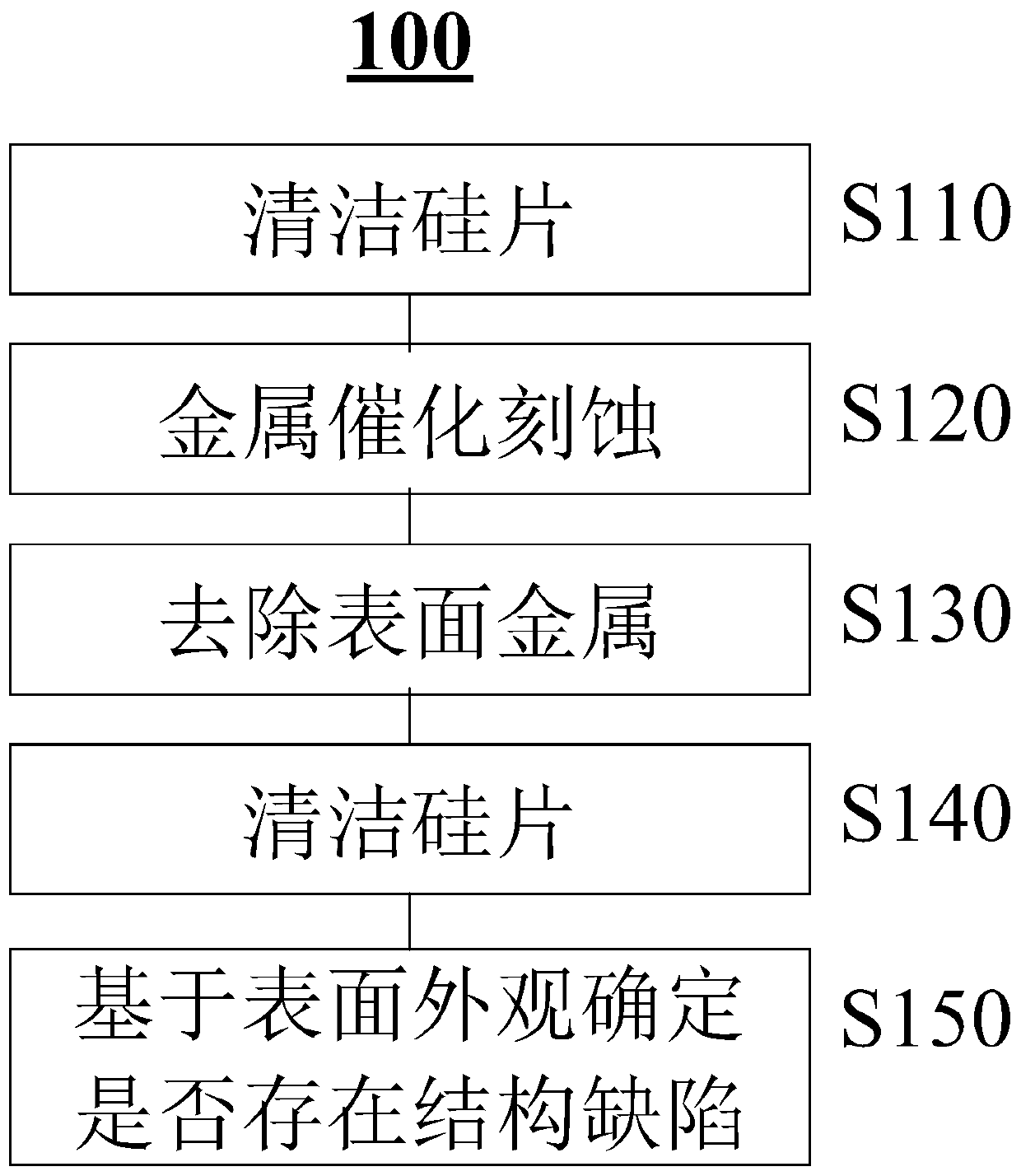

Method used

Image

Examples

example 1

[0034] Take a p-type (100) Czochralski monocrystalline silicon wafer with a size of 156mm×156mm (resistivity 1-3Ωcm), put it into acetone and ethanol for ultrasonic cleaning for 5 minutes, and then use deionized water to ultrasonically clean the silicon wafer.

[0035] The cleaned silicon wafer is immersed in an acidic metal-catalyzed etching solution composed of copper nitrate, hydrofluoric acid and hydrogen peroxide for etching treatment. Wherein, the concentration of copper nitrate is 10mmol / L, the concentration of hydrofluoric acid is 4.5mol / L, and the concentration of hydrogen peroxide is 0.5mol / L. The reaction temperature is 40° C., and the etching is performed for 10 minutes.

[0036]The etched silicon wafer was taken out, cleaned ultrasonically with 69wt% nitric acid to remove metal Cu covered on the surface of the silicon wafer, then ultrasonically cleaned with deionized water, and dried with high-purity nitrogen.

[0037] Photographs of the obtained wafers are shown...

example 2

[0039] Take a p-type (100) Czochralski monocrystalline silicon wafer with a size of 156mm×156mm (resistivity 1-3Ωcm), put it into acetone and ethanol for ultrasonic cleaning for 5 minutes, and then use deionized water to ultrasonically clean the silicon wafer.

[0040] Dip the cleaned silicon wafer into a metal-catalyzed etching solution composed of copper nitrate, hydrofluoric acid and hydrogen peroxide, wherein the concentration of copper nitrate is 5 mmol / L, the concentration of hydrofluoric acid is 6 mol / L, and the concentration of hydrogen peroxide is 0.8 mol / L, the reaction temperature was 50°C, and the etching was performed for 5 minutes.

[0041] The etched silicon wafer was taken out, ultrasonically cleaned with 69 wt% nitric acid to remove metal Cu covered on the surface, then ultrasonically cleaned with deionized water, and dried with high-purity nitrogen.

[0042] Photographs of the obtained wafers are shown in Figure 2B middle. It can be seen that the appearan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com