Plastic film residue recovering and straw returning combined machine

A combined working machine and residual film recycling technology, applied in the direction of collectors, harvesters, crop processors, etc., can solve the problems of short walking distance, small loading capacity of the film collecting box, and unsatisfactory operation effect, so as to avoid clogging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

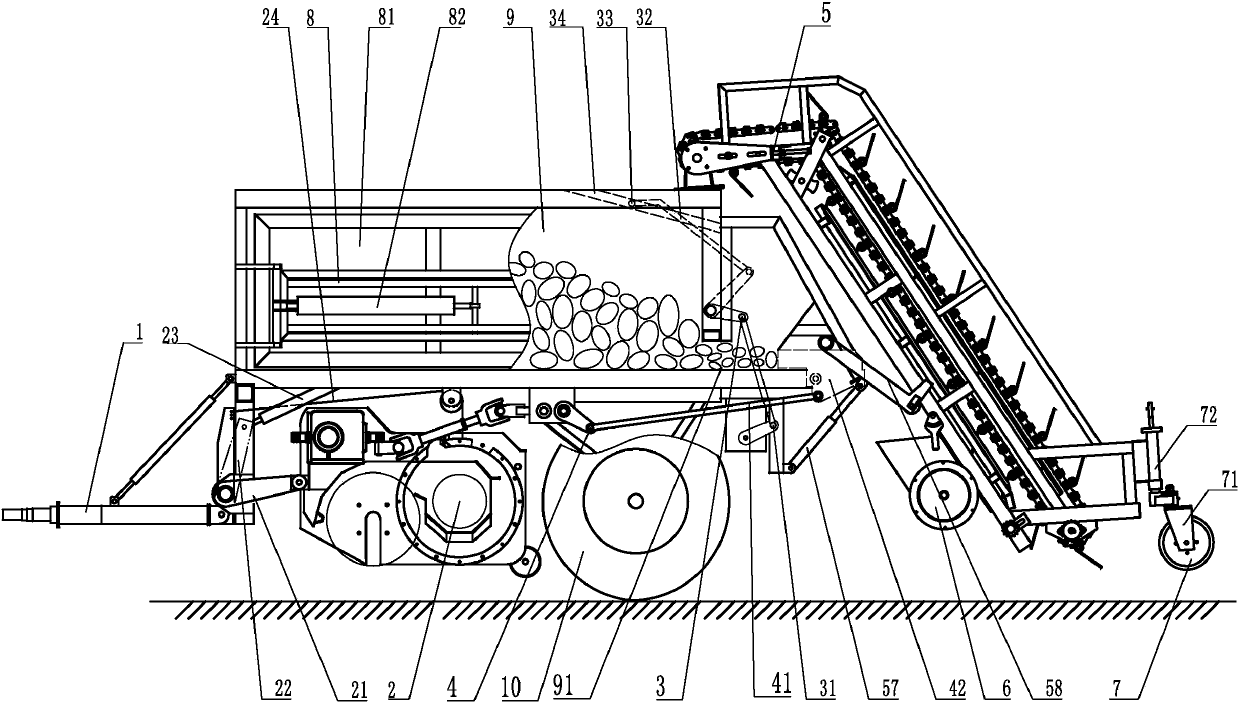

[0068] Embodiment 1: refer to Figure 1-2 , is a structural schematic diagram of Embodiment 1 of the present invention, a combined operation machine for recycling residual film and straw returning to the field, including a frame 1, a transmission system and a hydraulic system, and is characterized in that: the frame 1 is provided with a film collecting box A straw crushing and returning mechanism is arranged under the frame 1, and a film picking mechanism is arranged behind the film collecting box. The straw crushing and returning mechanism includes a straw crushing knife shaft 2, a straw crushing and returning machine suspension frame A21, a straw The suspension frame B22 of the crushing and returning machine, the lifting cylinder (23) and the steel wire rope (24) of the straw crushing and returning machine, one end of the suspension frame A21 of the straw crushing and returning machine and the suspension frame B22 of the straw crushing and returning machine are hinged to the ...

Example Embodiment

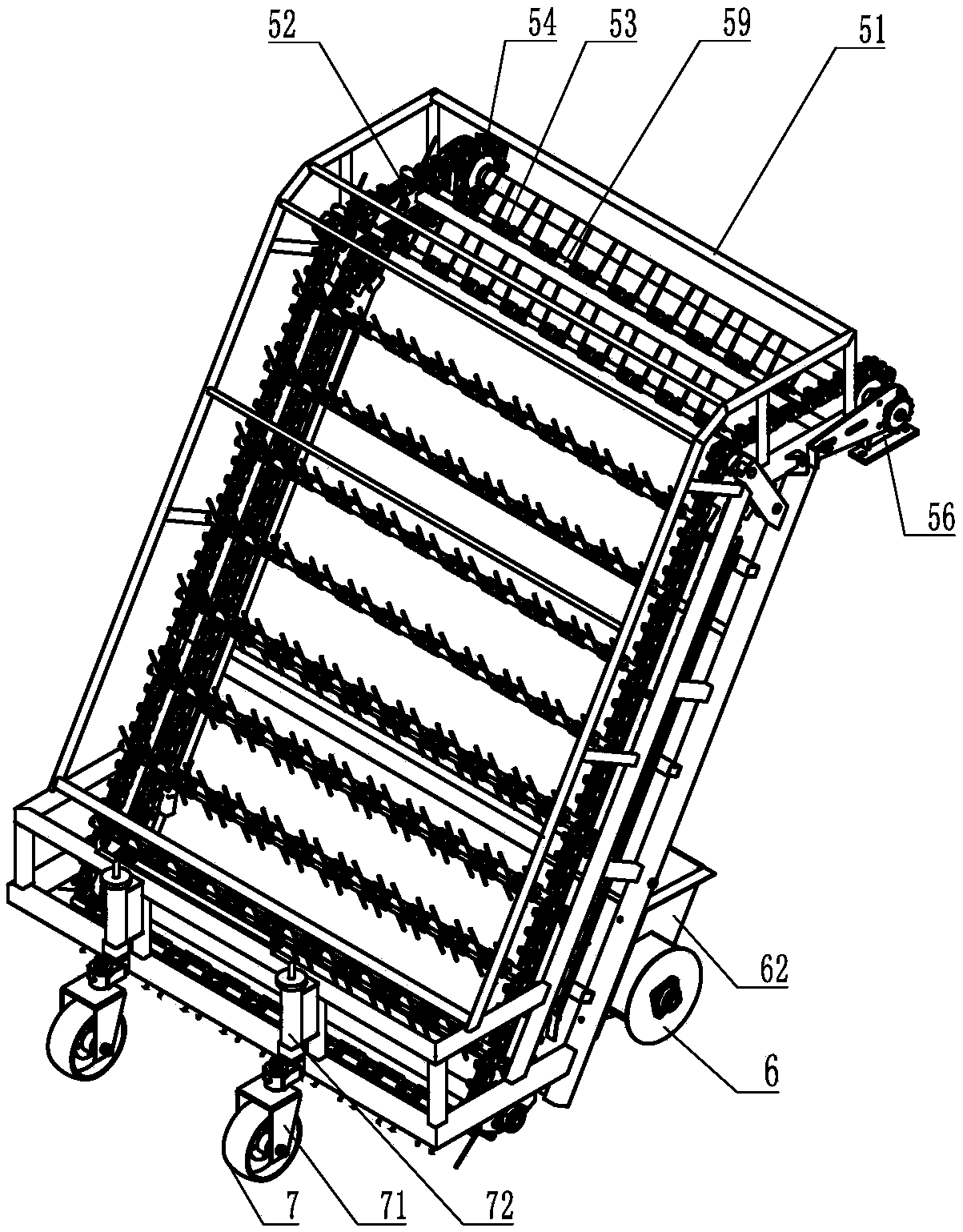

[0076] Embodiment 2: refer to Figure 3-6 , is a structural schematic diagram of Embodiment 2 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that: the driving device includes a sprocket 54 and a chain 52, the sprocket 54 is connected to the bracket 51, and the rake Both ends of the tooth installation pipe 59 are connected to the chain 52 , and the chain 52 is connected to the bracket 51 through the sprocket 54 .

[0077] The conveying device 63 at least includes a miscellaneous delivery shaft 631 and a helical blade 632, and the helical blade 632 includes a part of left-handed blades and a part of right-handed blades.

[0078] The top of the bracket 51 is provided with a chain rake hinge seat 56, one end of the chain rake hinge seat 56 is connected to the frame 1, and the other end is connected to the bracket 51, the chain rake frame can rotate relative to the chain rake hinge seat, and the lift cylinder 57 Adjust the support bar 58...

Example Embodiment

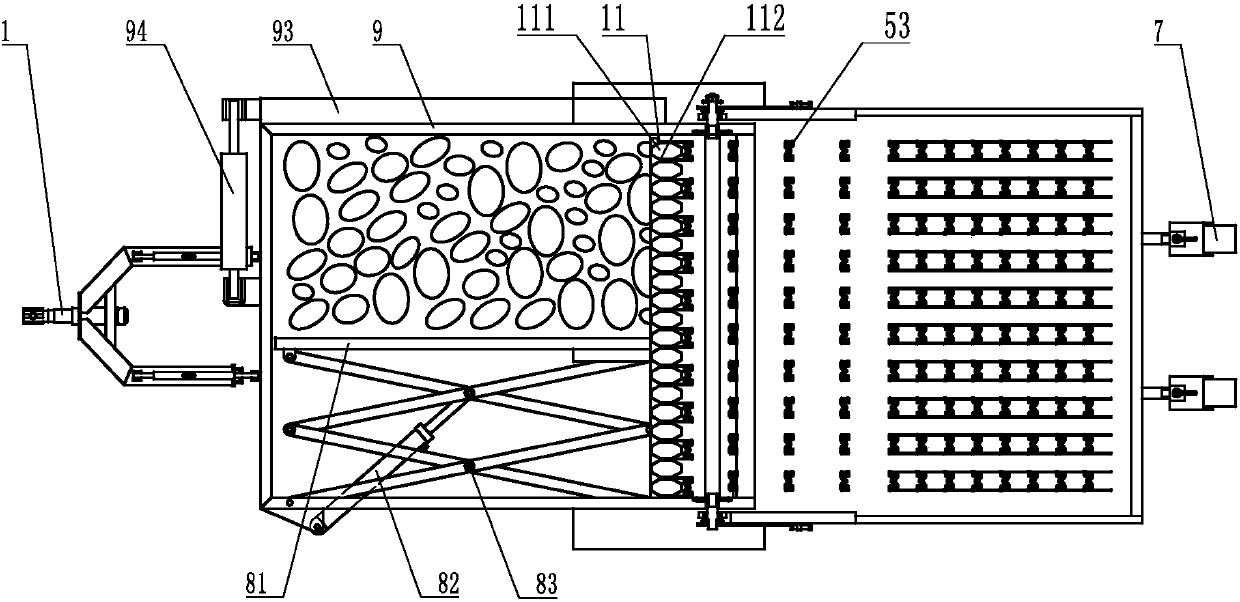

[0082] Embodiment 3: refer to Figure 7-9 , is a schematic structural view of Embodiment 3 of the present invention. Compared with Embodiment 1, the difference of this embodiment is that the unloading mechanism at least includes a film-pushing telescopic frame 83, a telescopic frame oil cylinder 82, and a discharge push plate 81. The film-pushing telescopic frame 83 is a folding frame, and the discharge push plate 81 is arranged in the inner cavity of the box body 9. One end of the film-pushing telescopic frame 83 is connected with the telescopic frame oil cylinder 82, and the other end is connected with the discharge push plate 81. Connect, along with the expansion and contraction of telescopic frame oil cylinder 82, drive and push away film telescopic frame 83 and drive unloading push plate 81 and do telescopic motion in casing 9 inner chambers.

[0083] Furthermore, the discharge baffle 93 is provided with a side-opening oil cylinder 94, one end of the side-opening oil cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com