Parallel pig hamstring withdrawing assembly line

An assembly line and pig's foot technology, applied in slaughtering, meat processing equipment, food science, etc., can solve problems such as difficult high-speed industrialization and low efficiency, and achieve the effect of improving efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

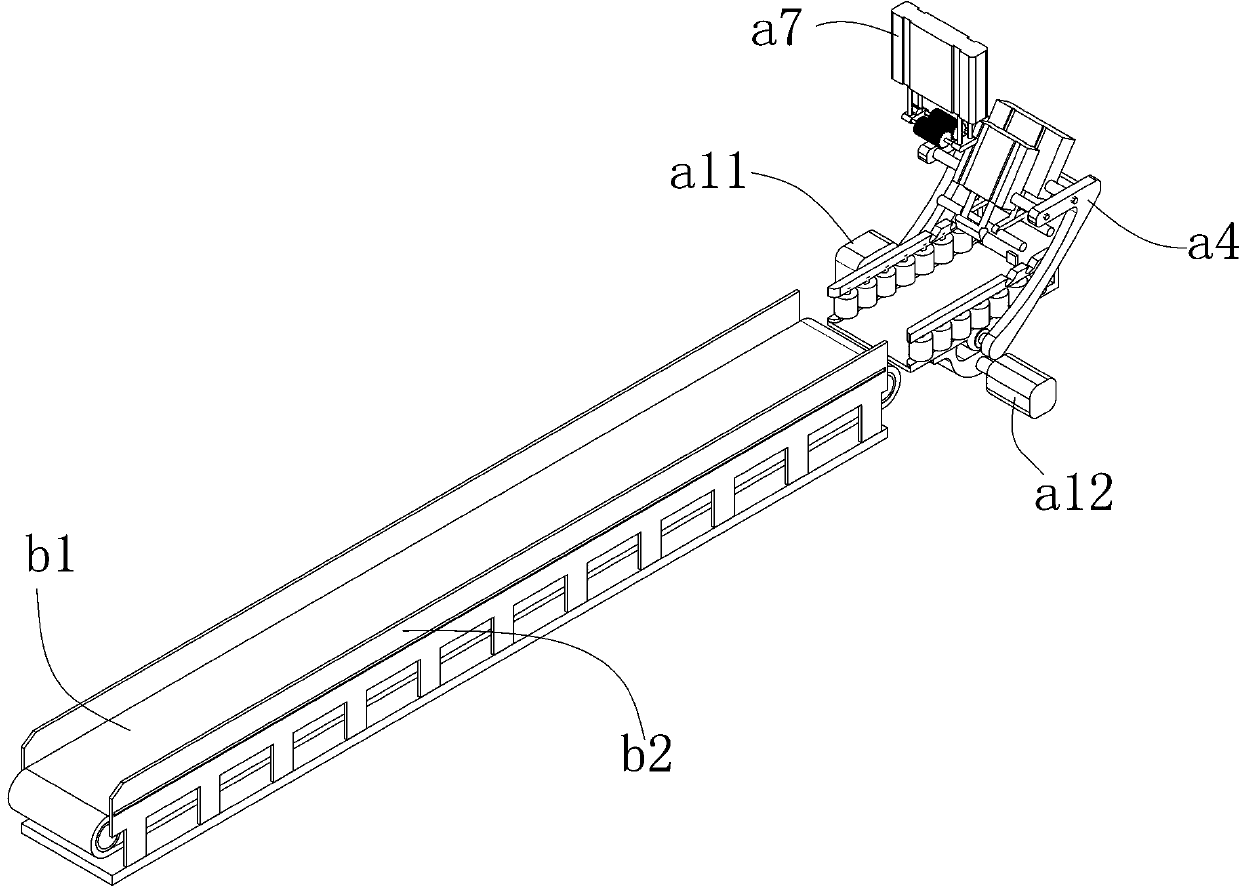

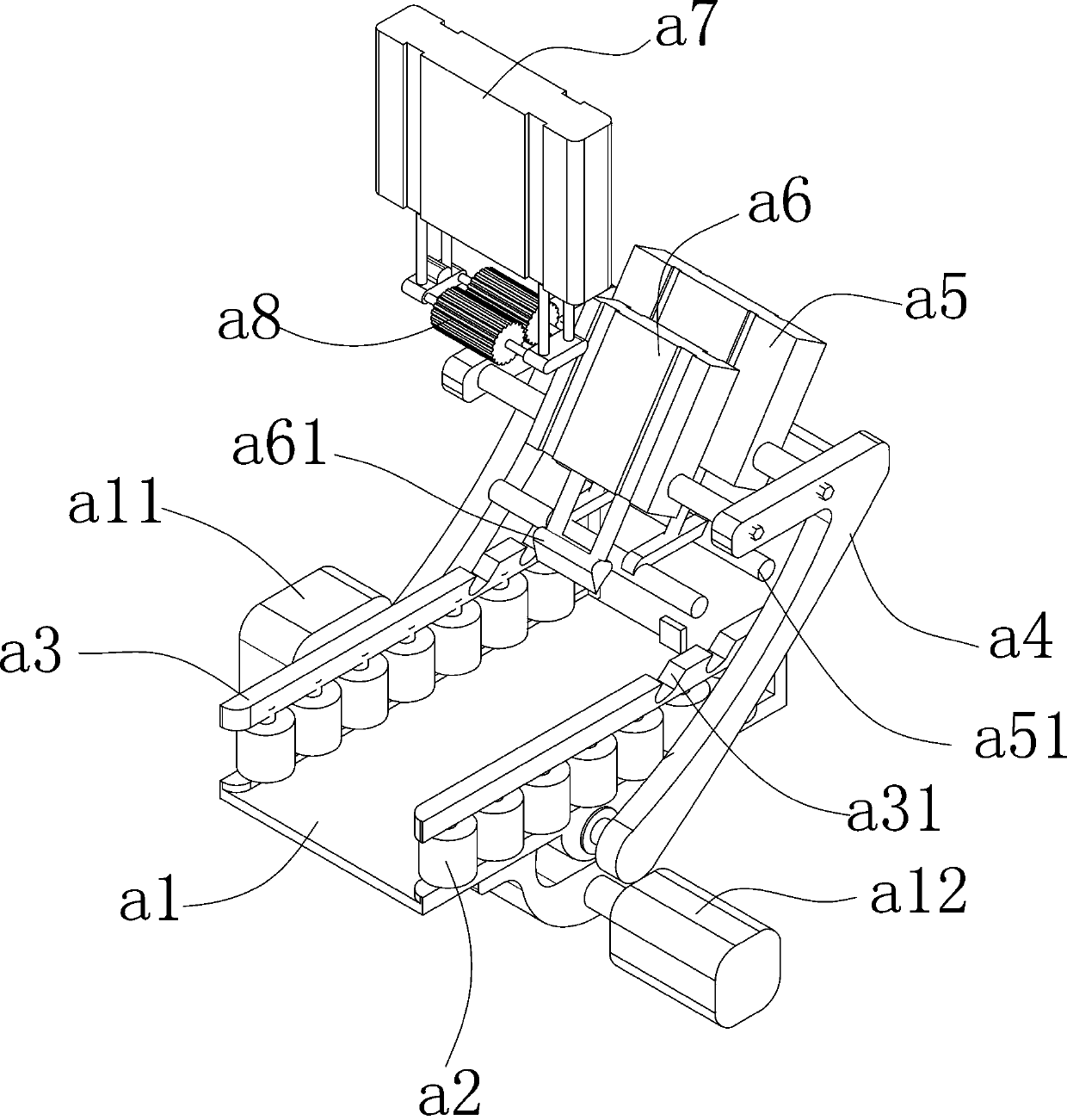

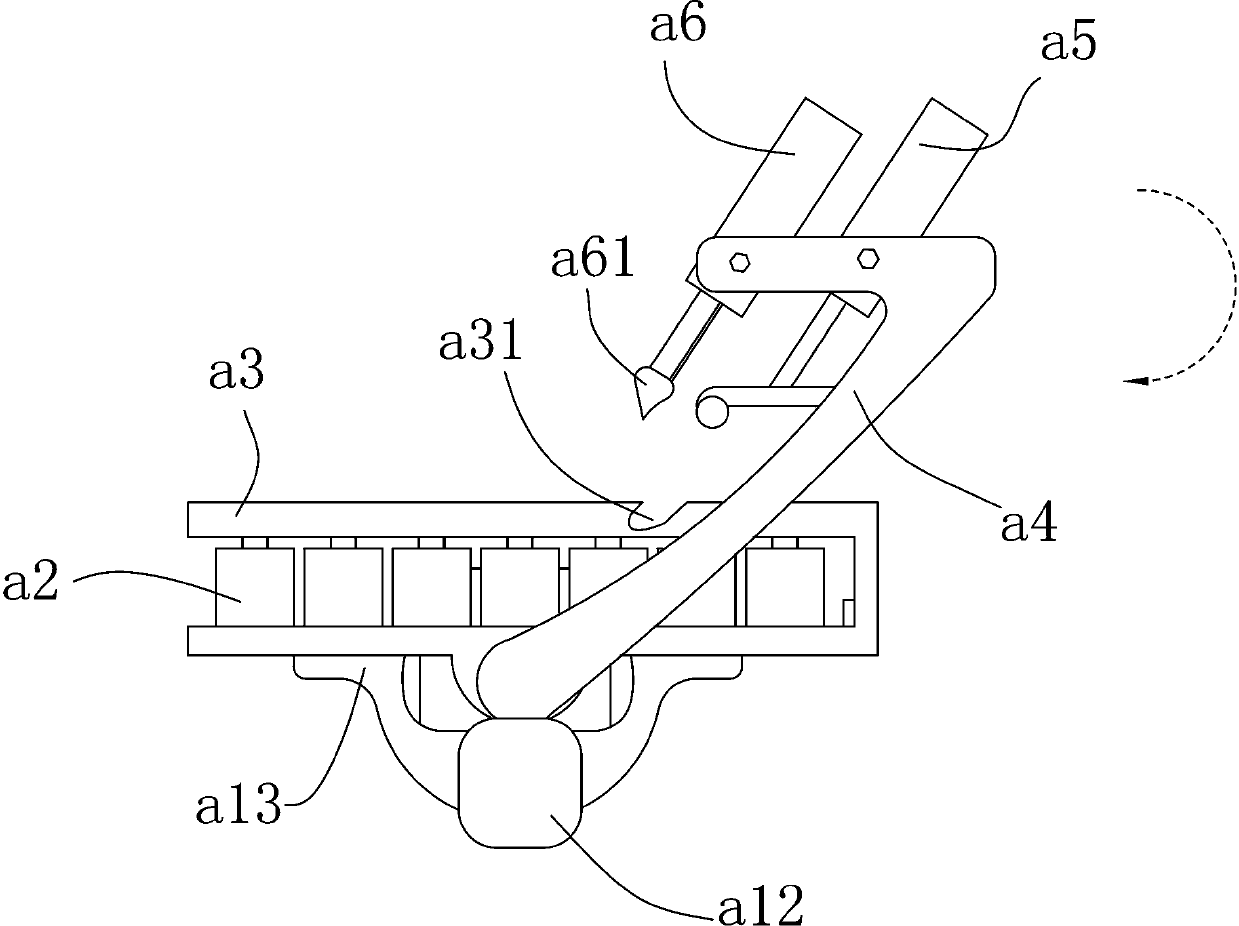

[0023] Such as Figure 1 to Figure 4 As shown, the pig's knuckle cramp assembly line described in this embodiment includes a main frame c1, a collection frame c2 is provided in the middle of the main frame, and two symmetrically arranged cramp devices are arranged on the main frame c1. Each cramping device includes a delivery platform and a cramping unit.

[0024] In the pig's foot cramp assembly line described in this embodiment, the conveying platform includes a conveyor belt b1 and guardrails b2 arranged on both sides of the conveyor belt b1;

[0025] The cramp unit includes a fixing mechanism and a tendon pulling mechanism; the fixing mechanism includes a load-bearing chassis a1, and a plurality of arranged rotating rollers a2 are pivotally connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com