Filter screen dust cleaner for electrical equipment

A technology for power equipment and power equipment boxes, which is applied in the field of filter dust remover, which can solve the problems of heavy workload of dust particles, achieve good cleaning effect, solve the problem of anti-clogging, and ensure the effect of heat dissipation channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

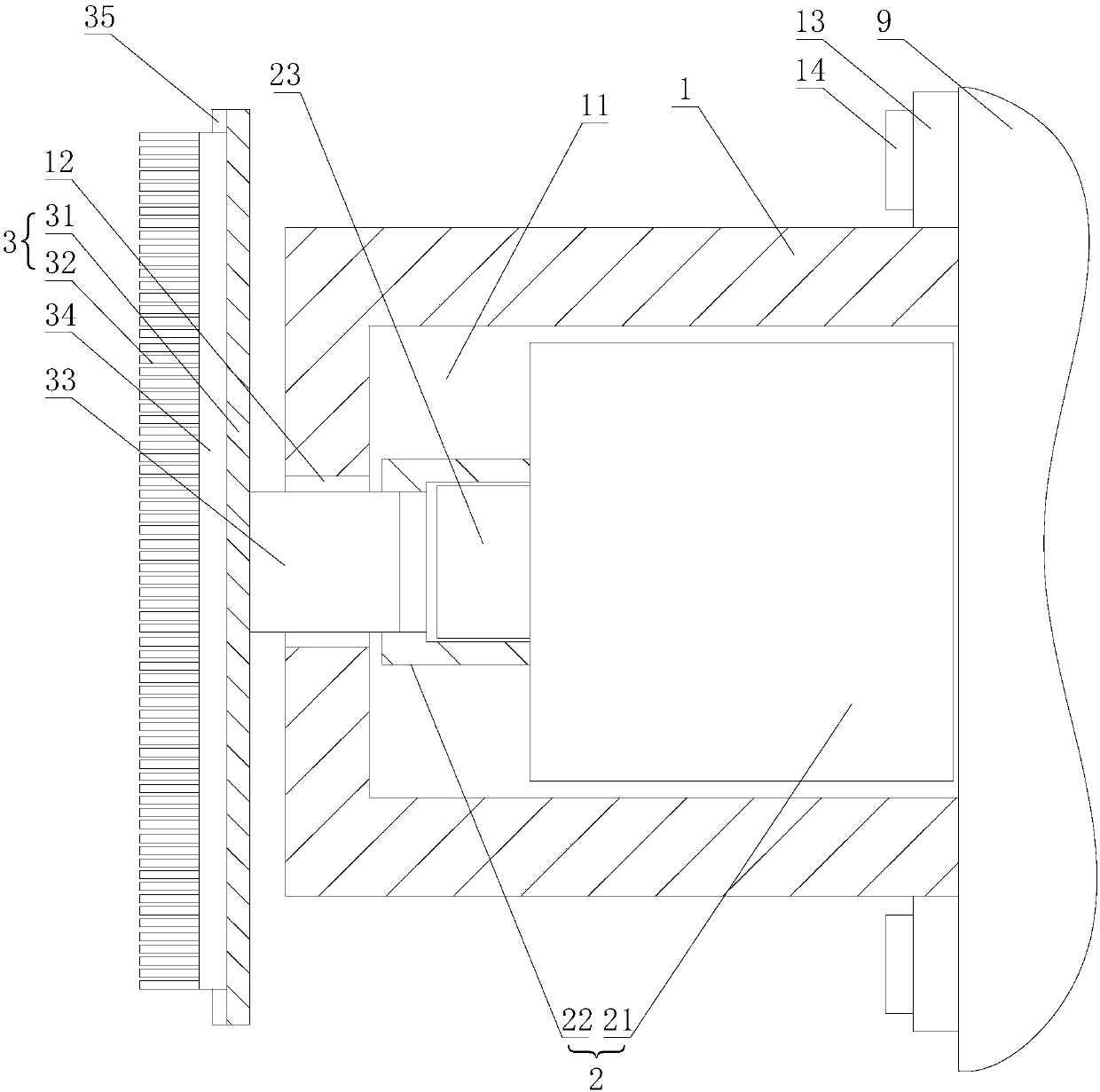

[0018] Such as figure 1 As shown, a filter dust remover for electric equipment includes a base 1, a driving mechanism 2 and a cleaning brush 3. The base 1 is provided with a first installation part 11 and a second installation part 12. The drive The mechanism 2 is installed on the base 1 through the first installation part 11, and the cleaning brush 3 is installed on the driving mechanism 2 through the second installation part 12, so that the entire filter dust remover is formed as a whole, reducing the entire filter dust The cleaning device takes up less space when installed, and the overall structure is compact and easy to assemble. The cleaning brush 3 relies on the driving force of the driving mechanism 2 to automatically clean the dust on the filter screen, which can ensure that the filter screen is not blocked, and can reduce the existing manual cleaning. The working intensity and cleaning quality can effectively solve the problem of anti-clogging of the filter screen, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com