Pin knocking mechanism

A pin and body technology, applied in the field of pin knocking mechanism, can solve the problems of easy to drop, inconvenience, etc., and achieve the effect of increasing service life, not easy to damage, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

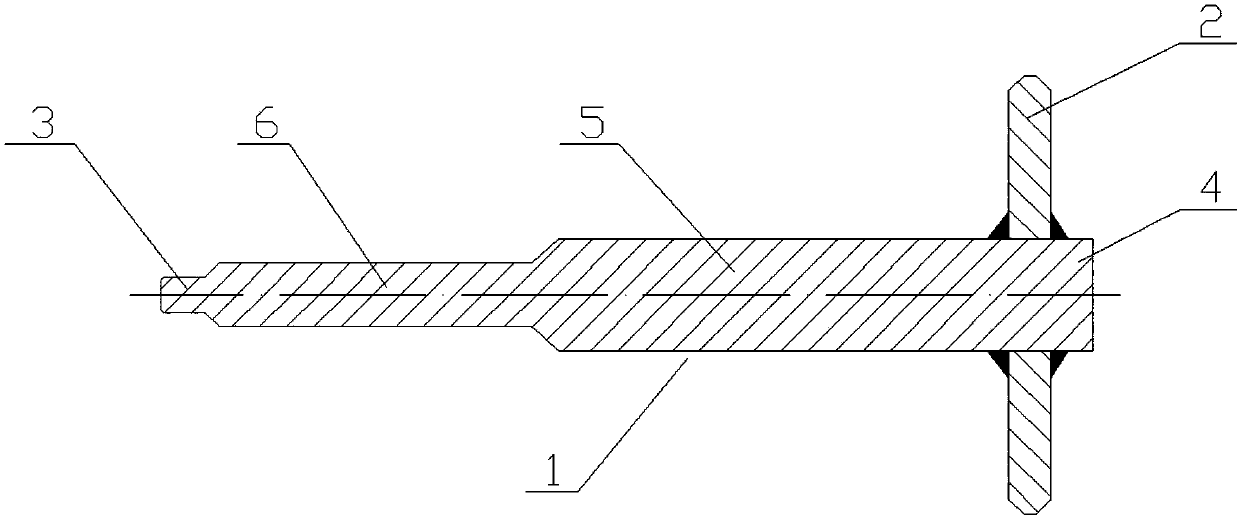

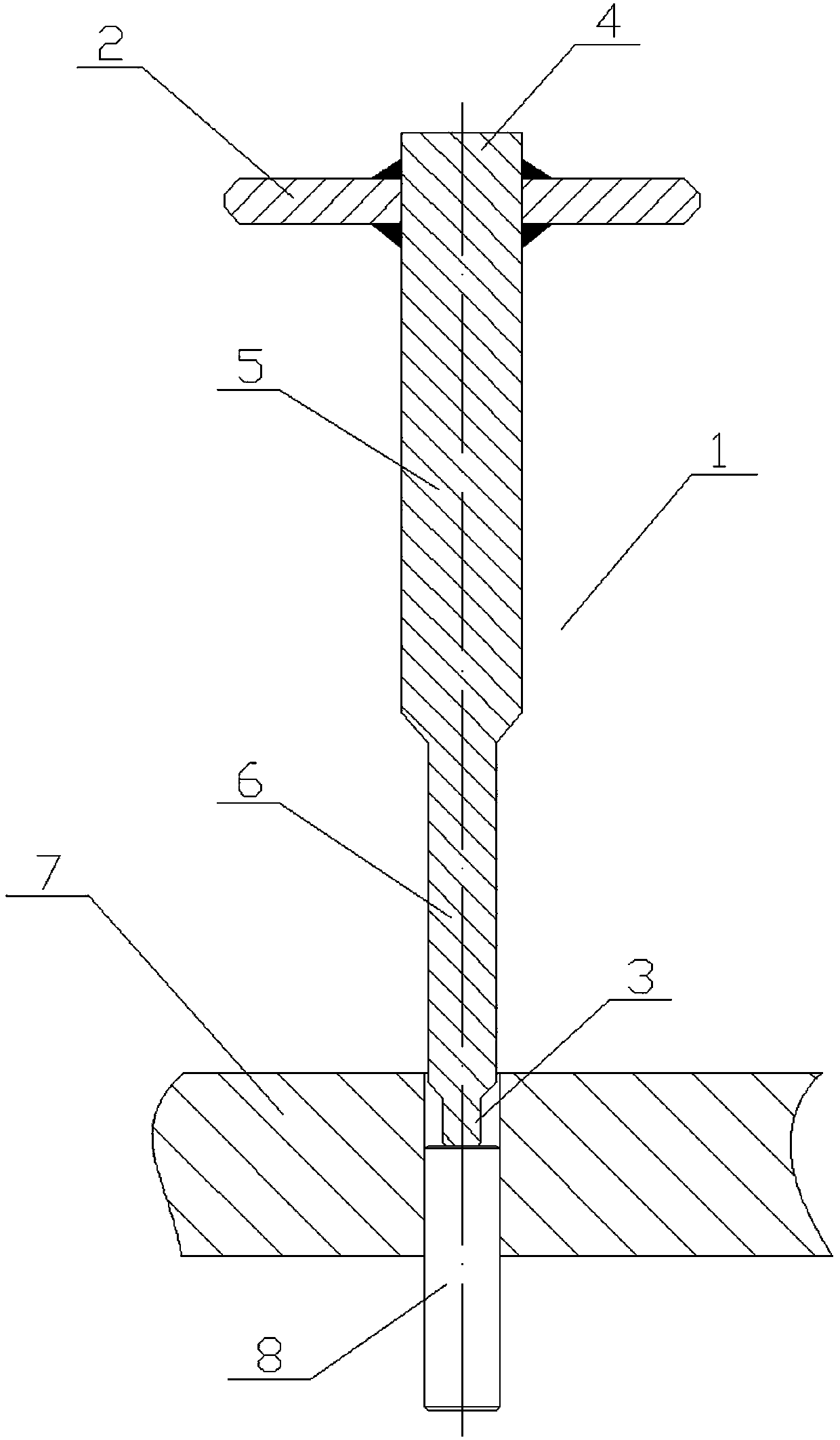

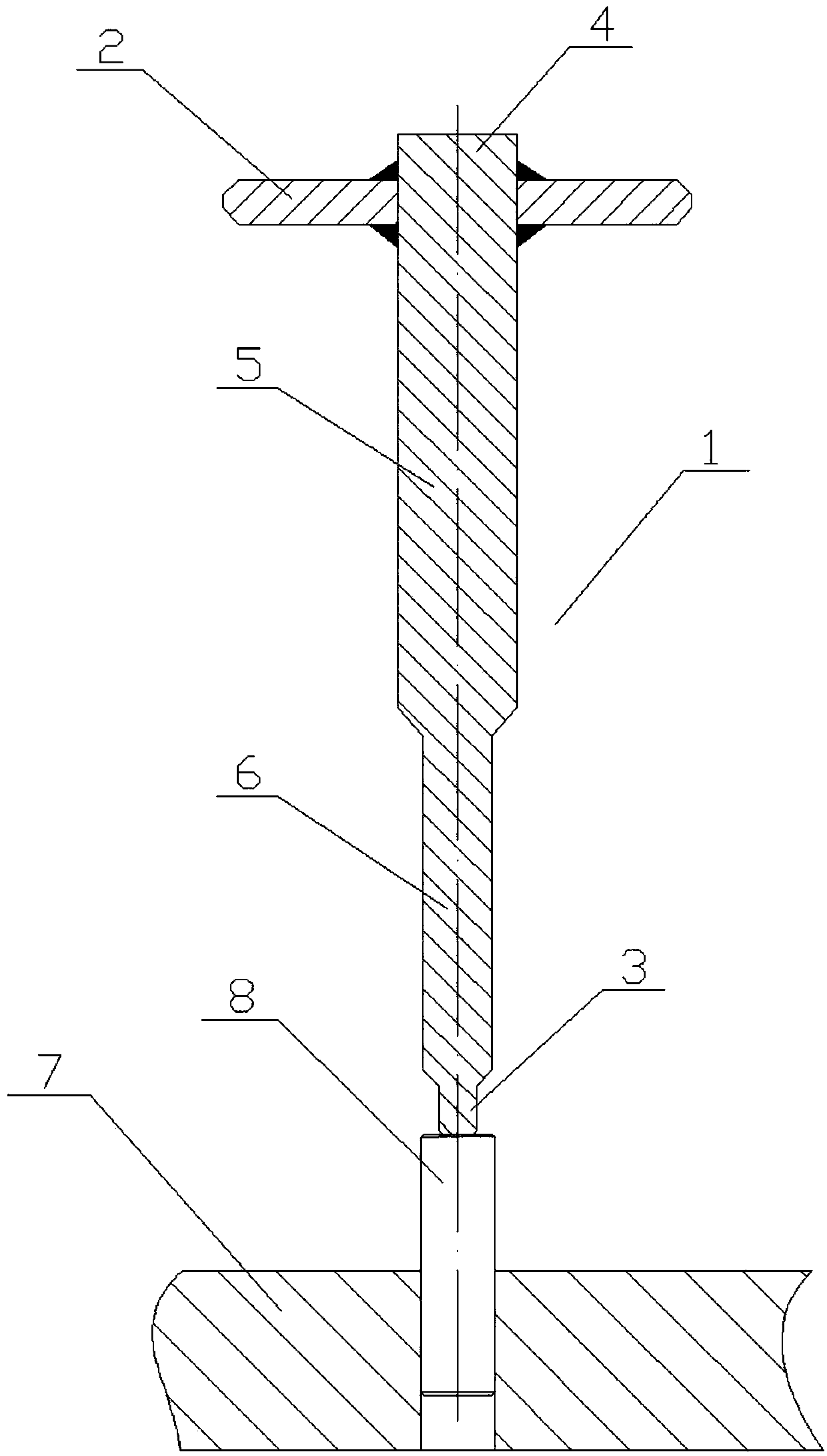

[0015] Such as figure 1 As shown, the pin knocking mechanism corresponding to a preferred embodiment of the present invention includes a main body 1 and a protective cover 2, and the main body 1 includes a handle part 5 and a top part 3 and a knocking part respectively connected to two ends of the handle part 5 4. The plug part 3 has undergone special treatment (such as heat treatment, modulation treatment, etc.) to make it have higher hardness, preferably its hardness is greater than that of the pin, so as to prevent it from being deformed and damaged during the knocking process; the length of the handle part 5 is preferably It is slightly longer than the length of the palm, and its diameter is suitable for people to hold; the striking part 4 is used to withstand the striking of a hammer, hammer, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com