Screen printing plate

A screen printing plate and mesh technology, applied in printing, printing plate, printing process, etc., can solve the problems of not considering breakage, not giving, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0062]

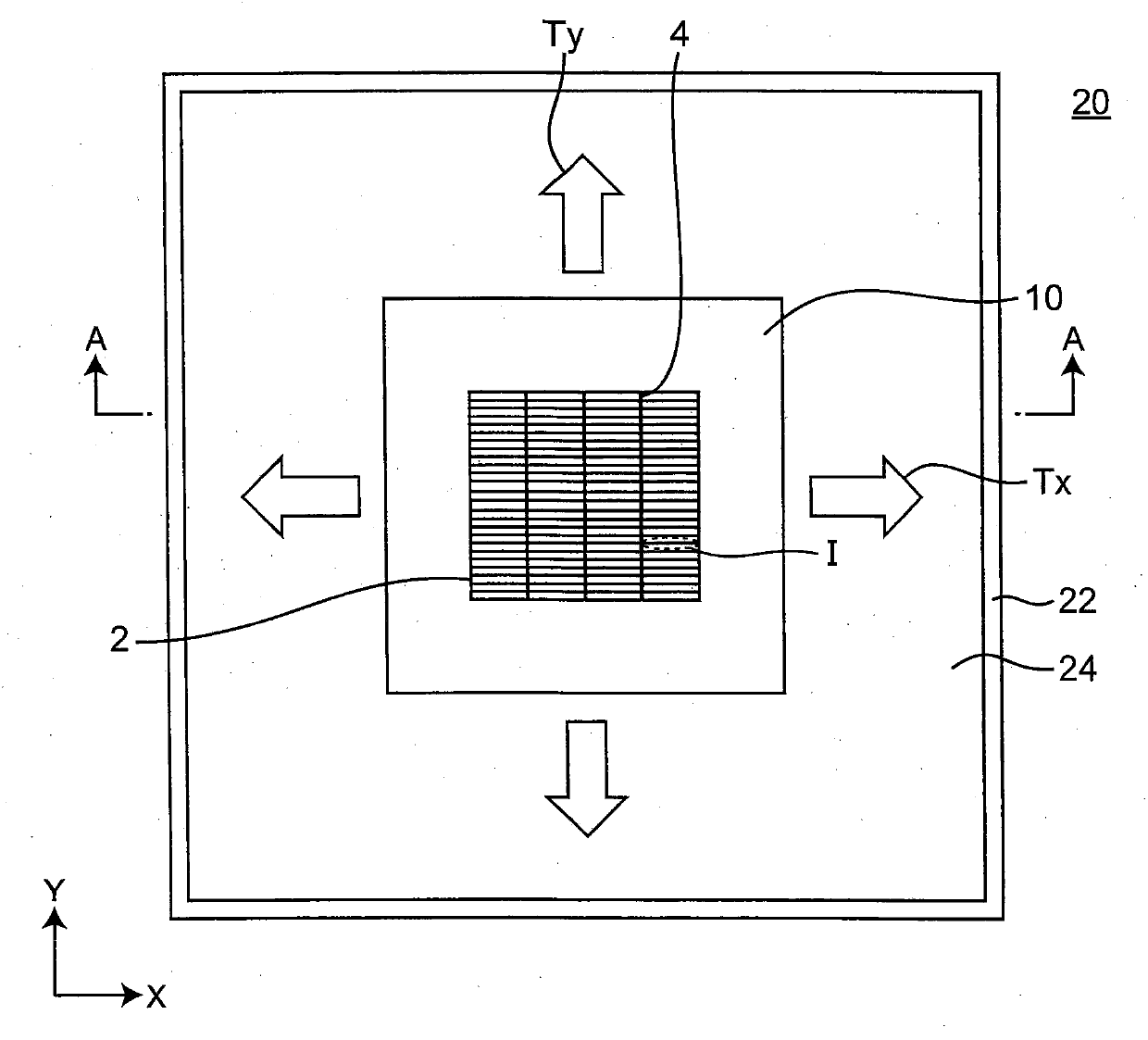

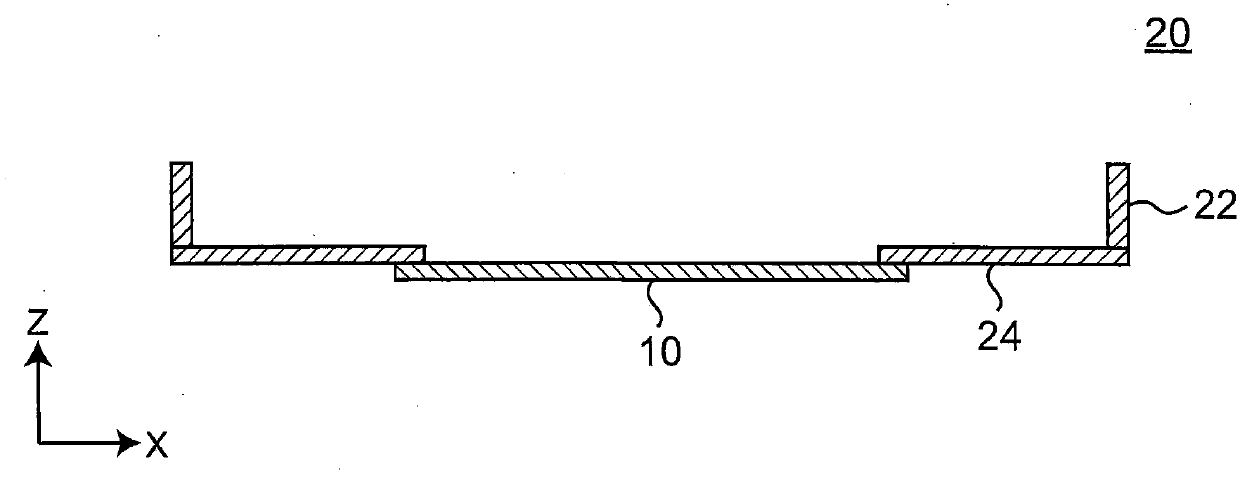

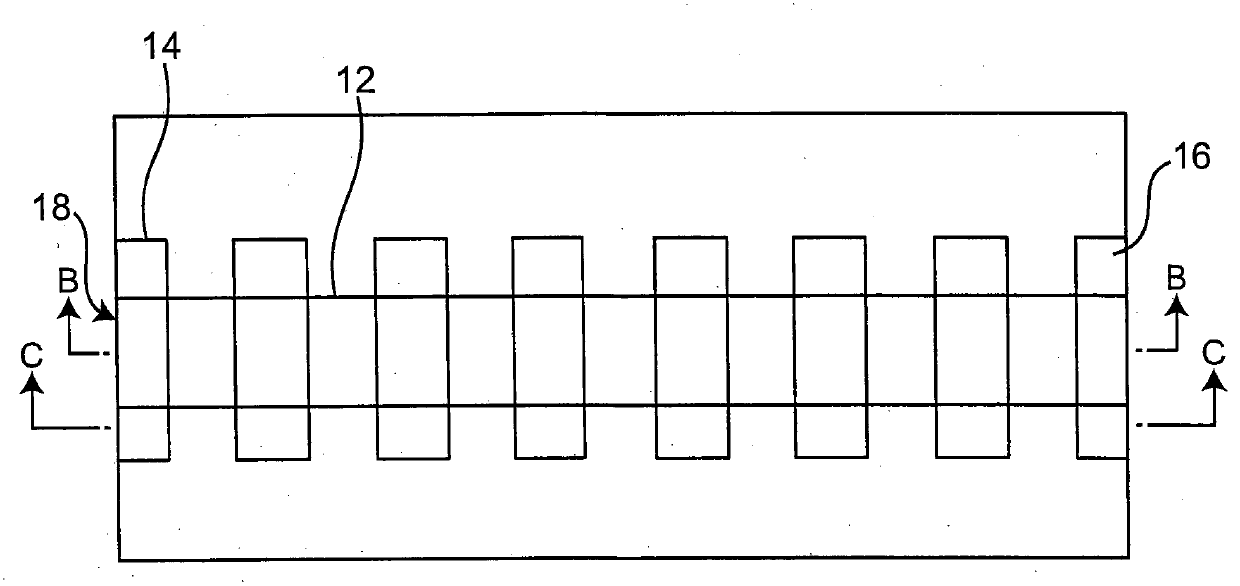

[0063] figure 1 It is a plan view showing the outline of the screen printing plate 20 according to the first embodiment. figure 2 is along figure 1 A brief cross-sectional view viewed from the A-A direction. Figure 3A yes figure 1 A partial enlarged plan view of the region I of the finger electrode pattern of the screen printing plate.

[0064] Such as figure 1 , figure 2 As shown, in this screen printing plate 20 , the above-mentioned rolled metal foil mesh member 10 is disposed on an aluminum frame 22 via a mesh fabric 24 or the like woven with polyester thin threads. The screen printing plate 20 has: the above-mentioned rolled metal foil mesh member; Figure 3A Resin 16 covering a plurality of openings 14 arranged along one direction; and line pattern 18 formed by opening and dividing resin 16 with a width ranging from 10 μm to 60 μm are shown. The longitudinal direction of the line pattern 18 is one direction, and the line pattern 18 is provided over t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com