Adsorbent, heat storage system containing the same, iron-aluminium phosphate and its producing method

An iron-aluminum phosphate and adsorbent technology, applied in the field of adsorbents, can solve problems such as waste heat reduction, achieve the effects of preventing fuel efficiency from declining and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

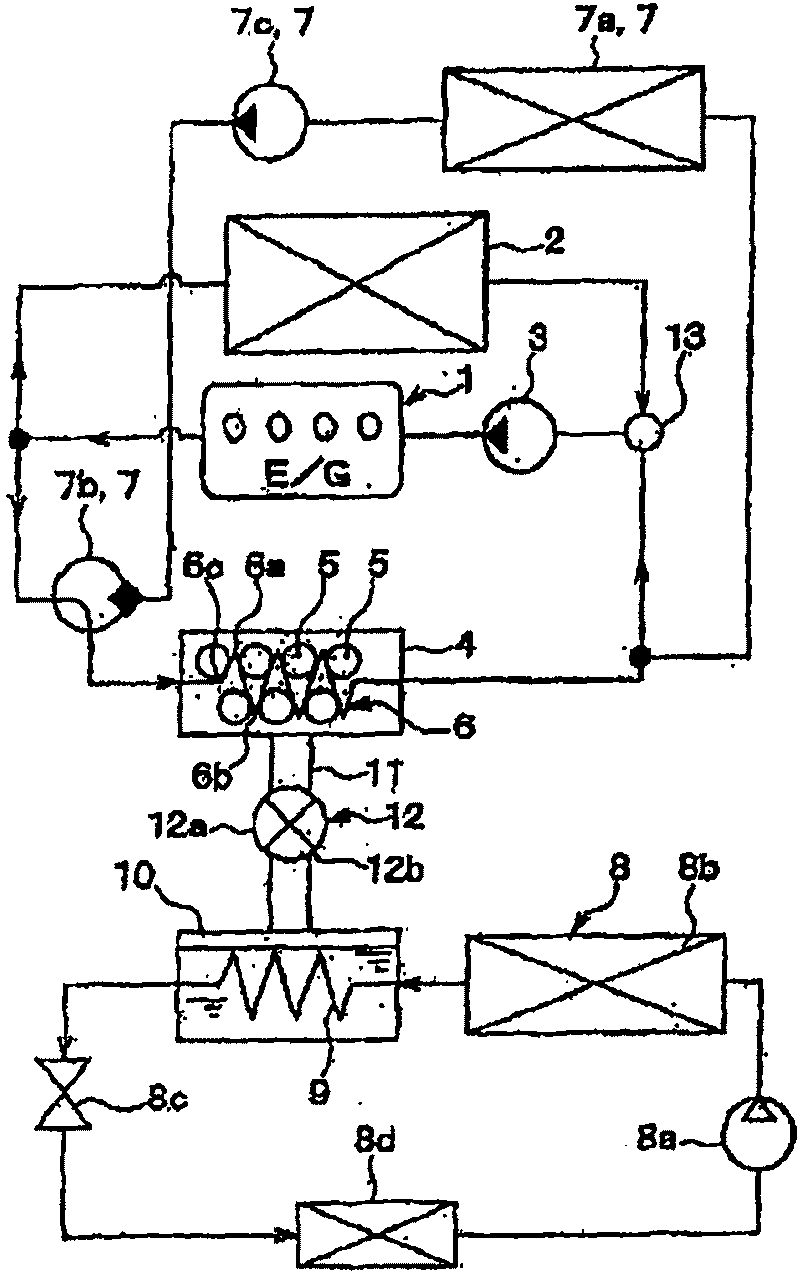

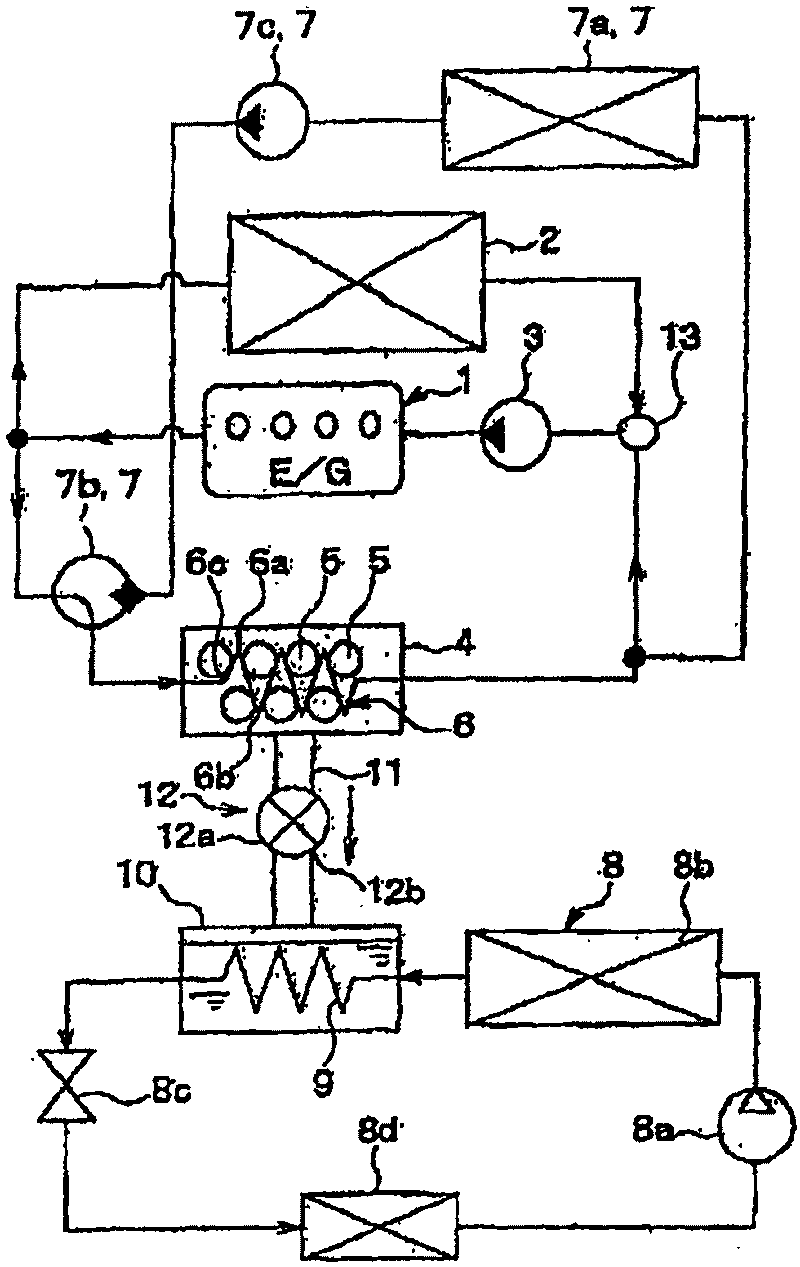

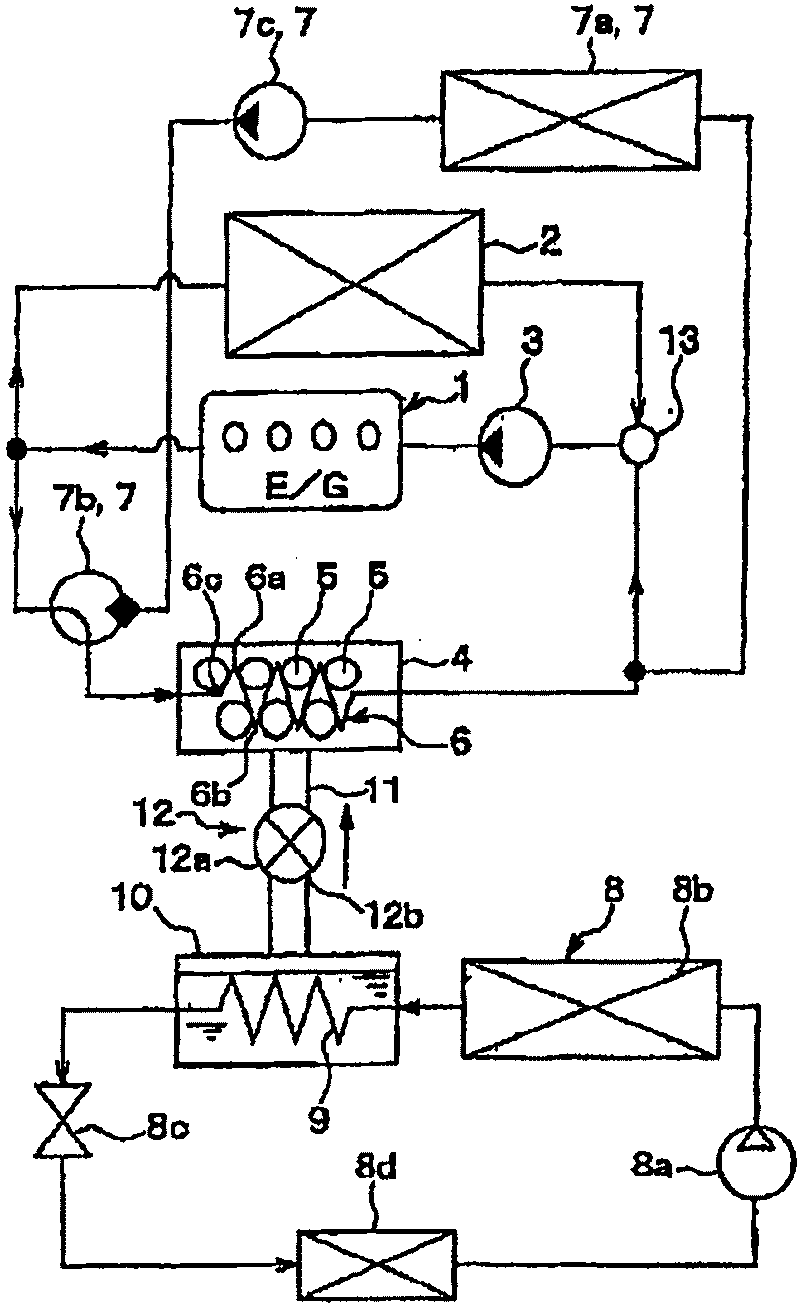

Image

Examples

Embodiment 1

[0310] Example 1 illustrates the production of FAPO-2 by using morpholine and triethylamine as templates.

[0311] To a mixture of 28.05 g of water and 11.53 g of 85% phosphoric acid, 6.8 g of pseudo-boehmite (containing 25% water, produced by Condea) was gradually added and stirred. This is Liquid A. In addition to liquid A, 2.78 g of ferrous sulfate heptahydrate, 5.05 g of morpholine, 4.35 g of triethylamine and 29 g of water were mixed to prepare a liquid. It was gradually added to Liquid A and stirred for further 3 hours to prepare a starting reaction mass having the following composition.

[0312] 0.2FeSO 4 :Al 2 o 3 :P 2 o 5 : 1.16 morpholine: 0.86 triethylamine: 70H 2 o

[0313] This starting reaction material was fed into a 200-cc stainless steel autoclave having a Teflon (registered trade name) inner cylinder, and reacted at 160° C. for 4 days while remaining still. After thus reacting, it was cooled, its supernatant liquid was removed by decantation, and the...

Embodiment 2

[0347] Zeolite was produced under the same conditions as in Example 1, however, the synthesized template-containing zeolite was calcined in nitrogen. Table 7 shows the XRD data of the zeolites thus obtained.

[0348] Table 7

[0349] 2θ

[0350] 2θ

[0351] Figure 9 is the water vapor-air isotherm of the zeolite measured at 55°C by using an adsorption isothermal calorimeter (Bellsorb 18, Nippon Bell). Specifically, the samples were analyzed under the following conditions: the adsorption temperature in the thermostat was 60°C; the adsorption temperature was 55°C; the initial pressure was 3.0 Torr, the pressure setting was 0; the saturated vapor pressure was 118.11 mmHg, and the equilibration time is 500 seconds.

Embodiment 3

[0353] The sample calcined in Example 2 was recalcined under the same conditions as in Example 1 in air. Table 7 shows the XRD data of the zeolites thus obtained. It can be seen that the recalcined zeolite is almost the same as the zeolite in Example 1.

[0354] Table 8

[0355] 2θ

[0356] 2θ

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption temperature | aaaaa | aaaaa |

| adsorption temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com