Safety belt coiler pretightening mechanism

A technology of seat belt retractor and pre-tensioning mechanism, which is applied in the direction of vehicle seat belts, belt retractors, transportation and packaging, etc., can solve the problems of complex structure, high manufacturing cost, slow response speed, etc., and achieve simple structure Compact, easy to use, and improved preload efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

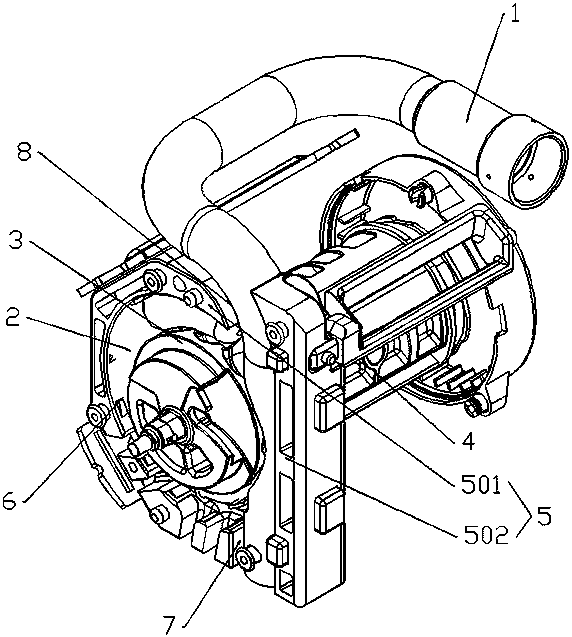

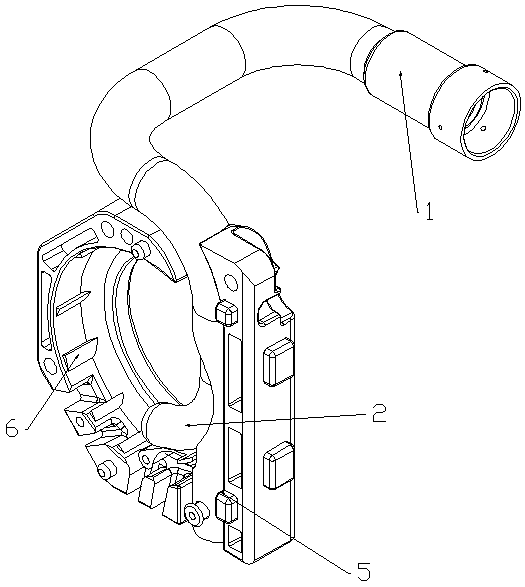

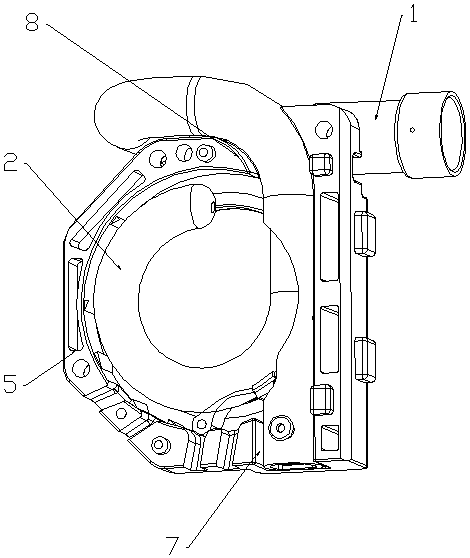

[0030] see Figure 1-Figure 5 As shown, the present invention provides a seat belt retractor pretensioning mechanism, including a special-shaped guide tube 1, a glue stick 2, a cover body 5 and a turbine 3, and the special-shaped guide tube 1 extends to the inside of the cover body 5 and Fixed installation, the special-shaped guide tube 1 is convenient to improve the compactness of the pre-tensioning mechanism, saves space, can be set according to space requirements, and is convenient to use; the turbine 3 is matched with the mandrel 4 and the turbine 3 is arranged on the cover 5 Inside, the mandrel 4 rotates synchronously with the turbine 3; the glue stick 2 extends between the cover 5 and the turbine 3 along the special-shaped guide pipe 1, and the glue stick 2 drives the The turbine 3 and the mandrel 4 pre-tighten the seat belt, the glue stick 2 is squeezed and deformed by the cover 5 and the turbine 3, and the deformed part cooperates with the turbine 3 to drive the turbin...

Embodiment 2

[0041] see Figure 6 As shown, the difference from the first embodiment is that a ratchet is provided on one side of the hemispherical groove, and the glue stick 2 can be clamped by using the ratchet to improve stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com