Adhesive tape fixing mechanism capable of being rapidly split

A fixing mechanism and tape technology, which is applied to the parts of strapping machinery, strapping objects, packaging/bundling objects, etc., can solve problems such as loosening, and achieve the effects of easy disassembly, good fixing function, and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

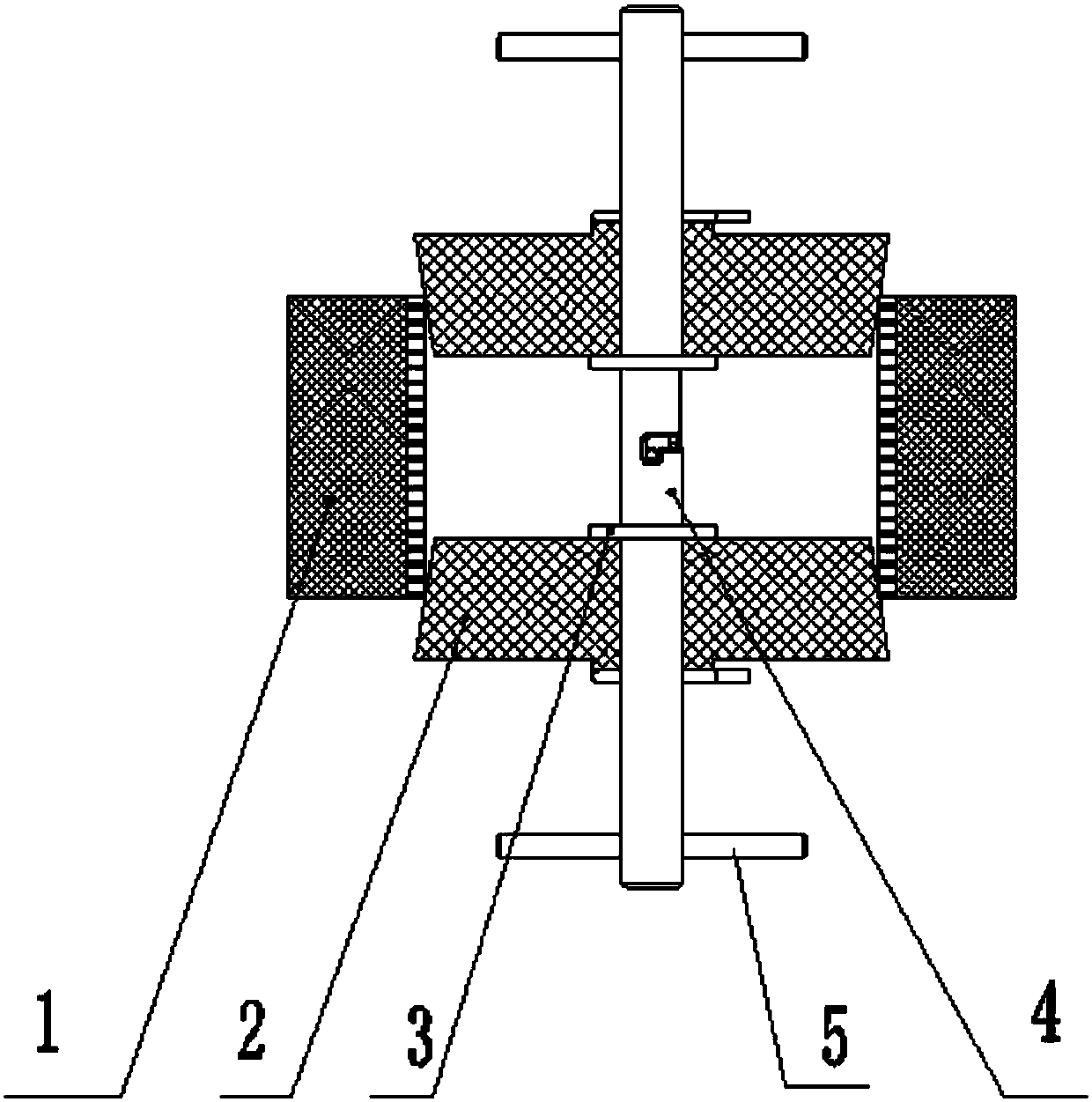

[0024] see figure 1 , a fast detachable adhesive tape fixing mechanism, comprising: a two-stage split shaft 4; it includes a first segment rod and a second segment rod that can be detached / installed from each other; an adhesive tape fixing seat 2; the The adhesive tape fixing seat 2 is in the shape of a round platform, and a pair of adhesive tape fixing seats 2 are sleeved and fixed on the first section of the rod and the second section of the bar respectively, with the small end of the round table facing inward; the adhesive tape 1; the adhesive tape 1 is annular, and the inner diameter of the adhesive tape is Between the outer diameters of the tape holder 2 large end and the small end.

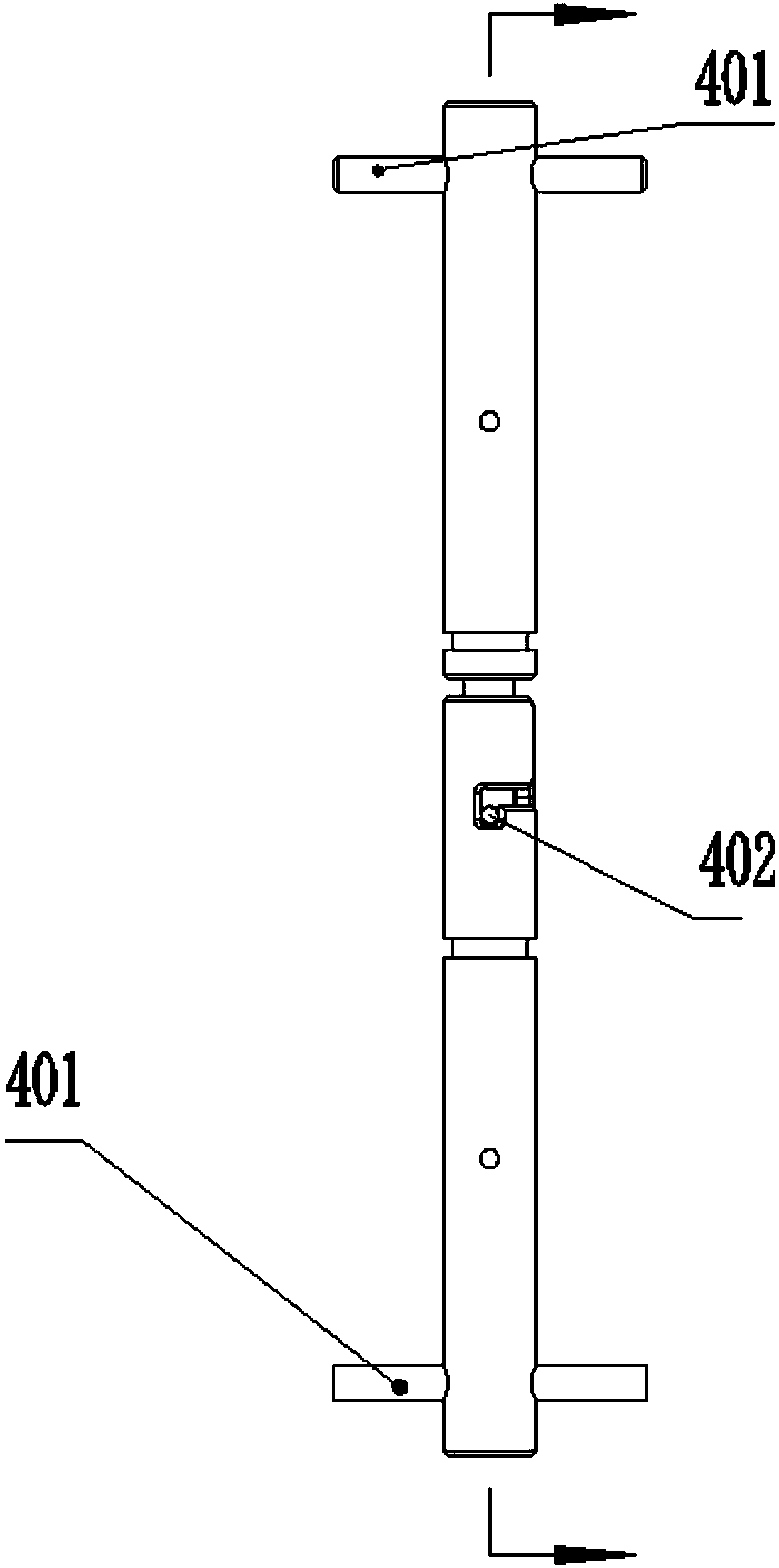

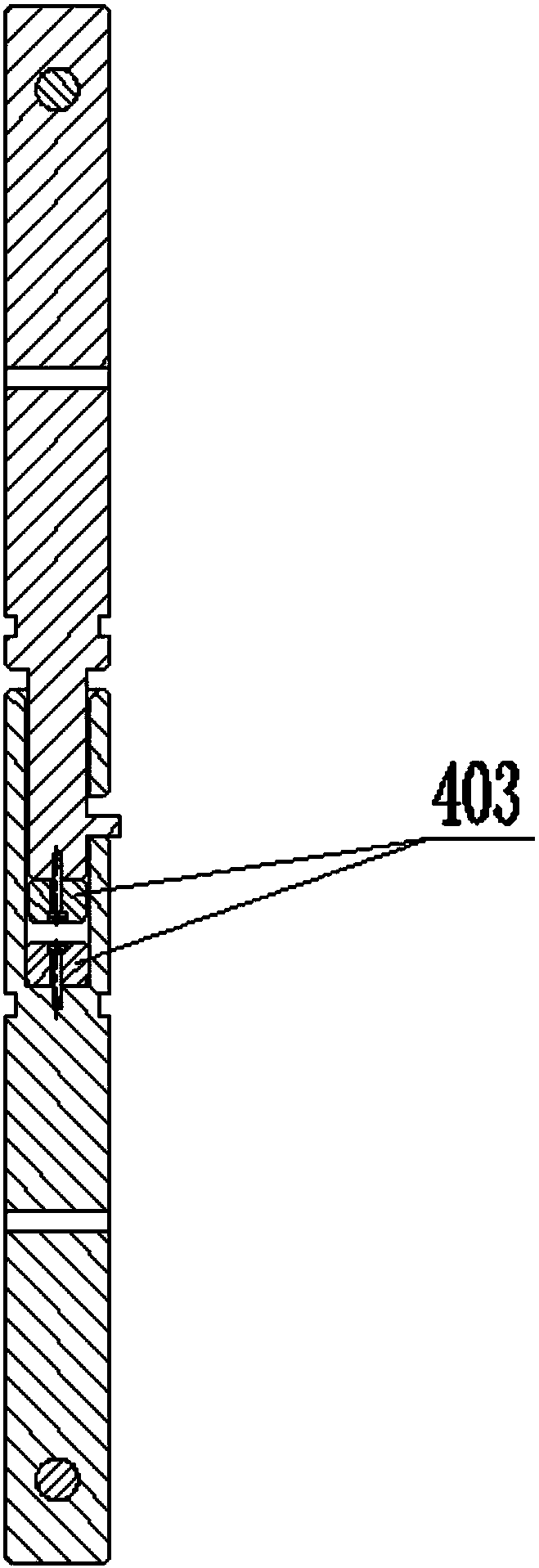

[0025] In this example, see Figure 1-2 , each segment of the bar is provided with a first pin hole, and the first pin hole 5 is installed on the first pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com