A compound soil improver for anti-heavy cropping specially used for facility agriculture

A soil conditioner and anti-heavy cropping technology, which is applied in the field of agricultural planting and soil conditioner, can solve problems such as shortage, weak technical support, and difficulty in implementing support policies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

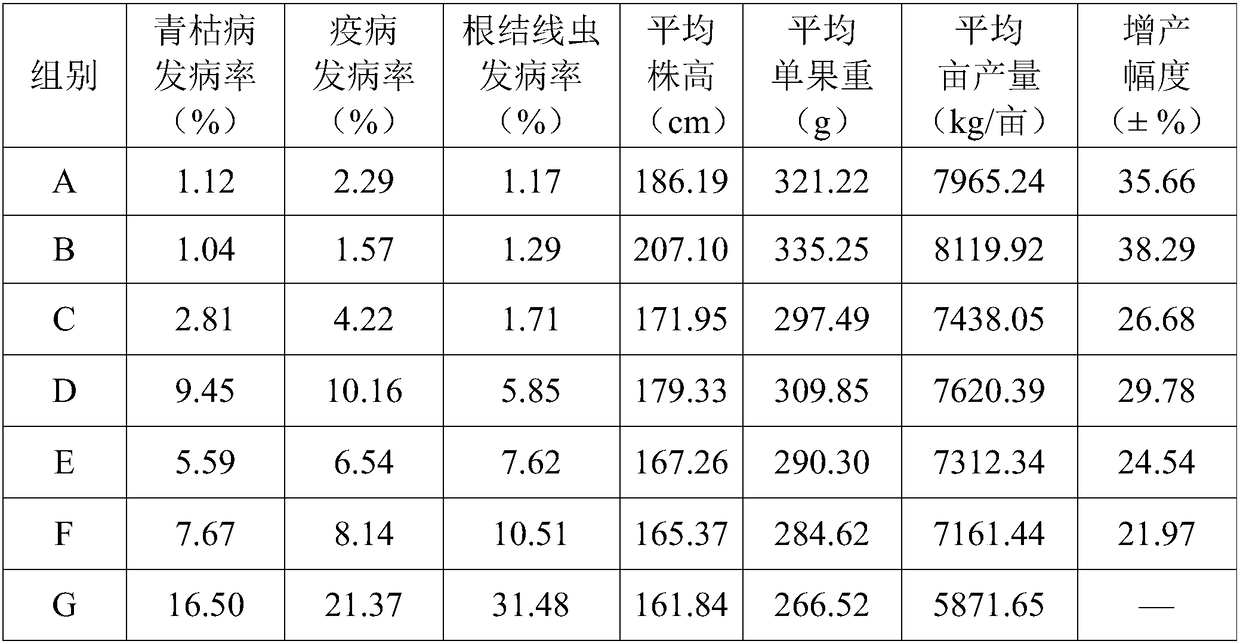

Examples

Embodiment 1

[0066] A compound soil improver for anti-repeated cropping is made from the following raw materials in parts by weight:

[0067] Wheat Straw 1000; Garlic Extract 1.0;

[0068] Herbal extract 0.30; Houttuynia cordata extract 0.60;

[0069] Nano chitosan 1.0; Composite trace elements 0.13;

[0070] The preparation method is as follows:

[0071] (1) Wheat straw decomposing treatment: crush wheat straw into particles with a diameter of 0.1-0.3 cm, add 2.0 times of water to it, and simultaneously add a straw decomposing agent equivalent to 0.2% of the total weight of wheat straw, and the straw is decomposed The agent is prepared by the ratio of starter: brown sugar: water = 1:1:20. It is activated for 12 hours before use, and the above-mentioned wheat straw particles, water and straw decomposing agent are fully mixed to obtain a straw premix, and the straw premix is controlled. The moisture content of the material is 60-65%; the above-mentioned straw premix is stacked up, se...

Embodiment 2

[0079] A compound soil improver for anti-repeated cropping is made from the following raw materials in parts by weight:

[0080] Wheat Straw 900; Garlic Extract 0.95;

[0081] Herbal extract 0.25; Houttuynia cordata extract 0.55;

[0082] Nano chitosan 0.95; Composite trace elements 0.12;

[0083] The preparation method is as follows:

[0084] (1) Wheat straw decomposing treatment: crush wheat straw into particles with a diameter of 0.1-0.3 cm, add 1.8 times of water to it, and simultaneously add a straw decomposing agent equivalent to 0.3% of the total weight of wheat straw, and the straw is decomposed The agent is prepared by the ratio of starter: brown sugar: water = 1:1:20. It is activated for 8 hours before use. The above-mentioned wheat straw granules, water and straw decomposing agent are fully mixed to obtain a straw premix, and the straw premix is controlled. The moisture content of the material is 60-65%; the above-mentioned straw premix is stacked up, sealed ...

Embodiment 3

[0087] A compound soil improver for anti-repeated cropping is made from the following raw materials in parts by weight:

[0088] Wheat Straw 1050; Garlic Extract 1.10;

[0089] Herbal extract 0.35; Houttuynia cordata extract 0.65;

[0090] Nano chitosan 1.05; Composite trace elements 0.14;

[0091] The preparation method is as follows:

[0092] (1) Wheat straw decomposing treatment: crush wheat straw into particles with a diameter of 0.1-0.3 cm, add 2.0 times of water to it, and simultaneously add a straw decomposing agent equivalent to 0.1% of the total weight of wheat straw, and the straw is decomposed The agent is prepared by the ratio of starter: brown sugar: water = 1:1:20. It is activated for 24 hours before use, and the above-mentioned wheat straw granules, water and straw decomposing agent are fully mixed to obtain a straw premix, and the straw premix is controlled. The moisture content of the material is 60-65%; the above-mentioned straw premix is stacked up, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com