A needle seat device for quilt function shock absorption and noise reduction

A functional and noise reduction technology, applied in sewing machine needle seat, sewing machine components, sewing equipment, etc., can solve the problems of poor vibration damping effect of needle seat, hidden safety hazards, high noise, etc., and achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

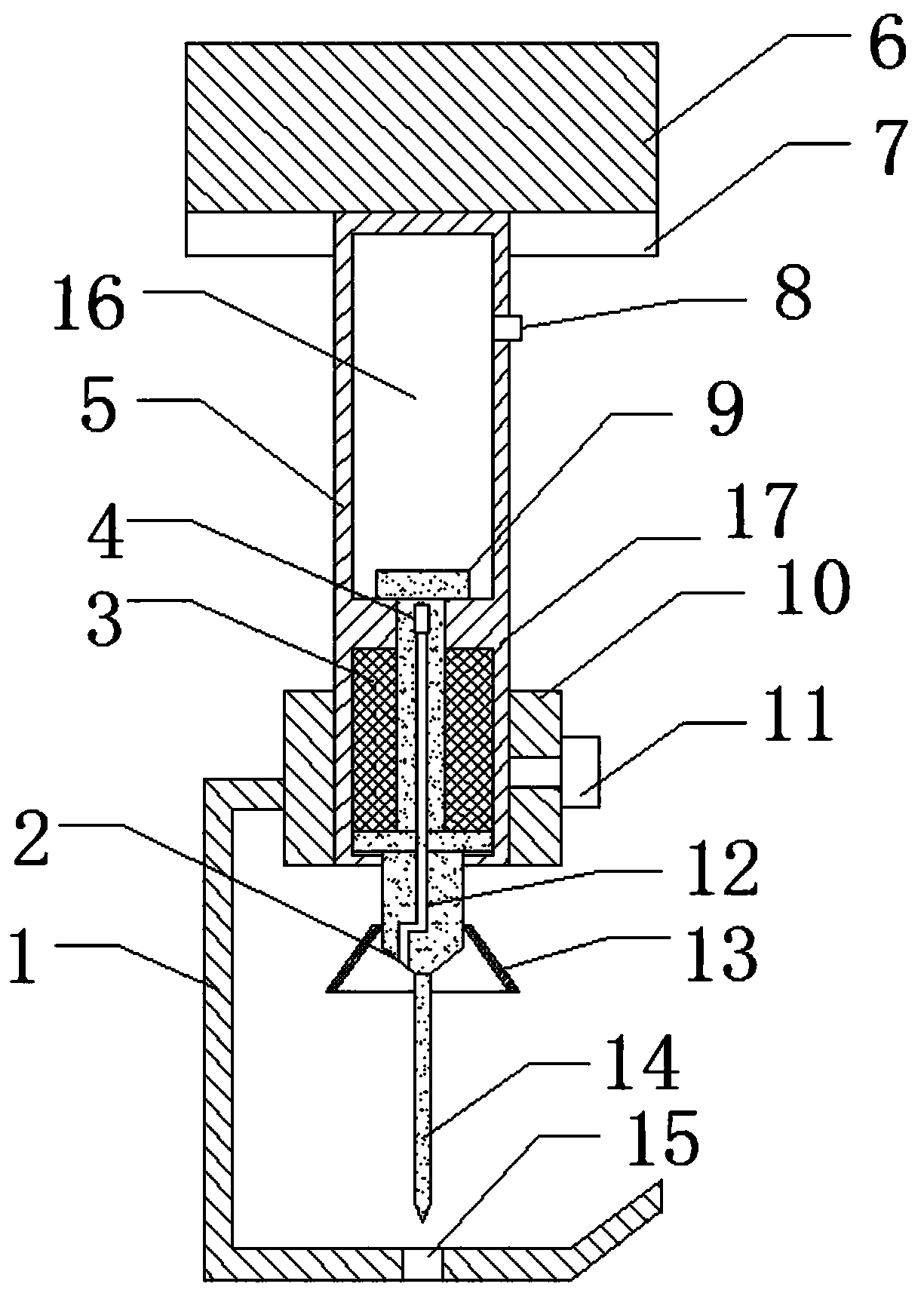

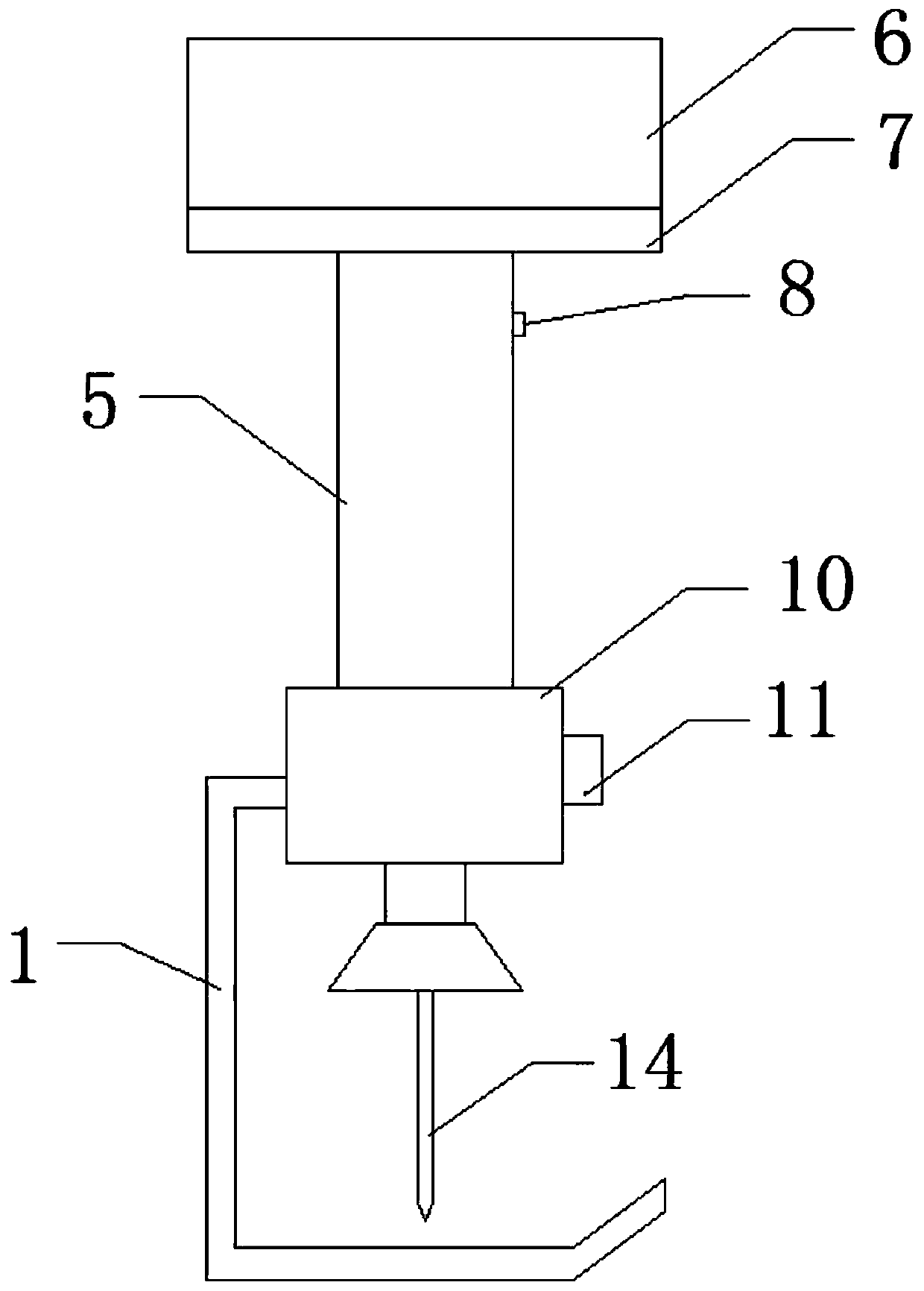

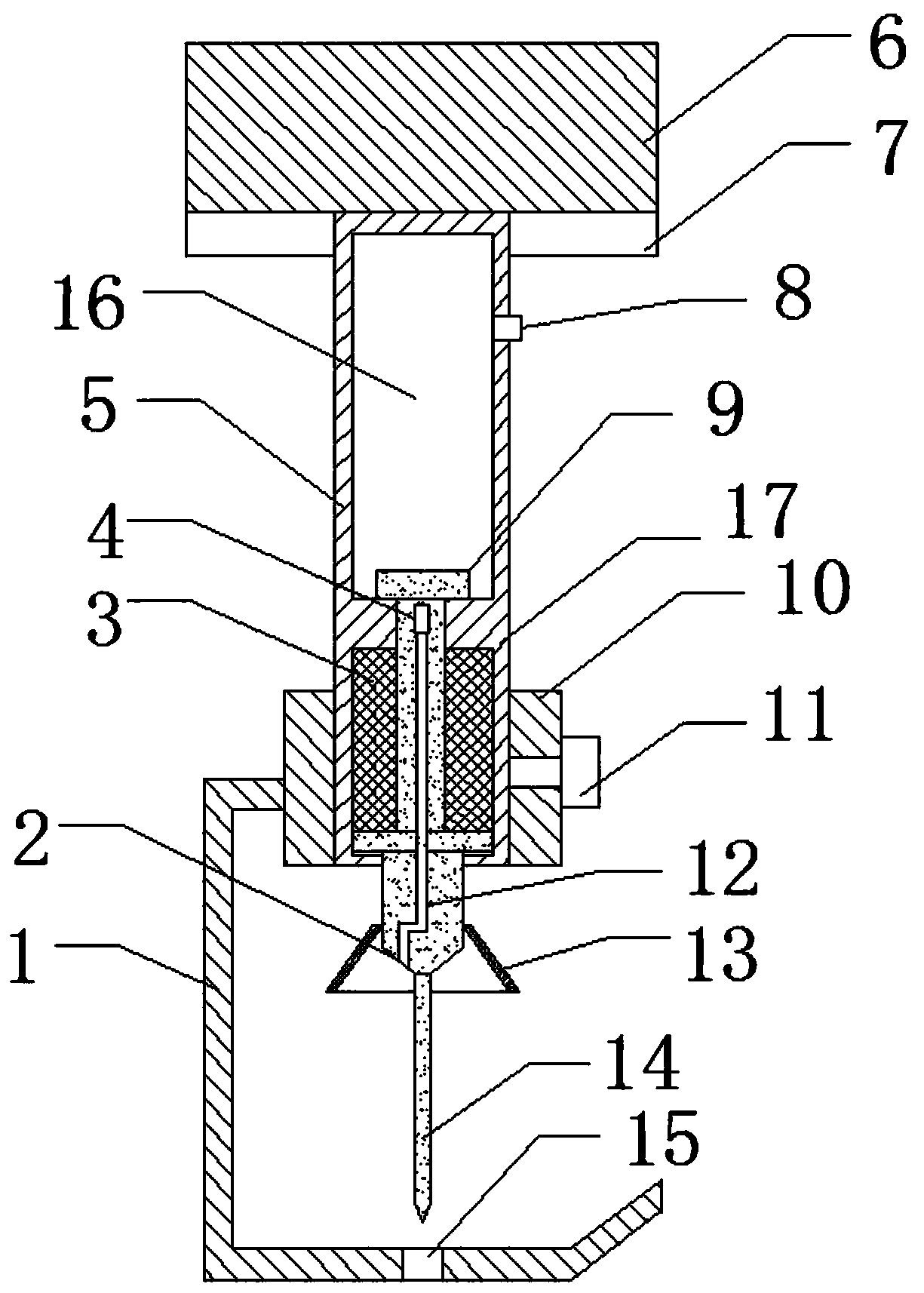

[0027] A needle base device for sewing quilts with function of shock absorption and noise reduction in this embodiment includes a needle bar base 6, a needle cylinder 5 and a connecting rod 9, and the lower surface of the needle bar base 6 is provided with a needle cylinder 5 and an annular ultraviolet germicidal lamp 7. A liquid storage chamber 16 is provided inside the syringe 5, a limit ring 17 is provided under the liquid storage chamber 16, and a rubber body 3 is provided on the lower surface of the limit ring 17, and the rubber body 3 is sleeved on the side wall of the middle part of the connecting rod 9; The side wall of the middle part of the rod 9 is provided with a liquid inlet 4, the inside of the connecting rod 9 is provided with a liquid passage 12 communicated with the liquid inlet 4, the bottom surface of the connecting rod 9 is provided with a liquid outlet 2 connected with the liquid passage 12, and the bottom of the connecting rod 9 is fixed. There is a metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com