Construction method of battery well

A construction method and battery technology, applied in the field of pipelines, can solve the problems affecting the stable and continuous operation of the station, the inability to monitor the state of the valve chamber, and the inability to supply power to related equipment, so as to reduce equipment investment and construction costs, reduce construction procedures and Material, convenient operation and maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

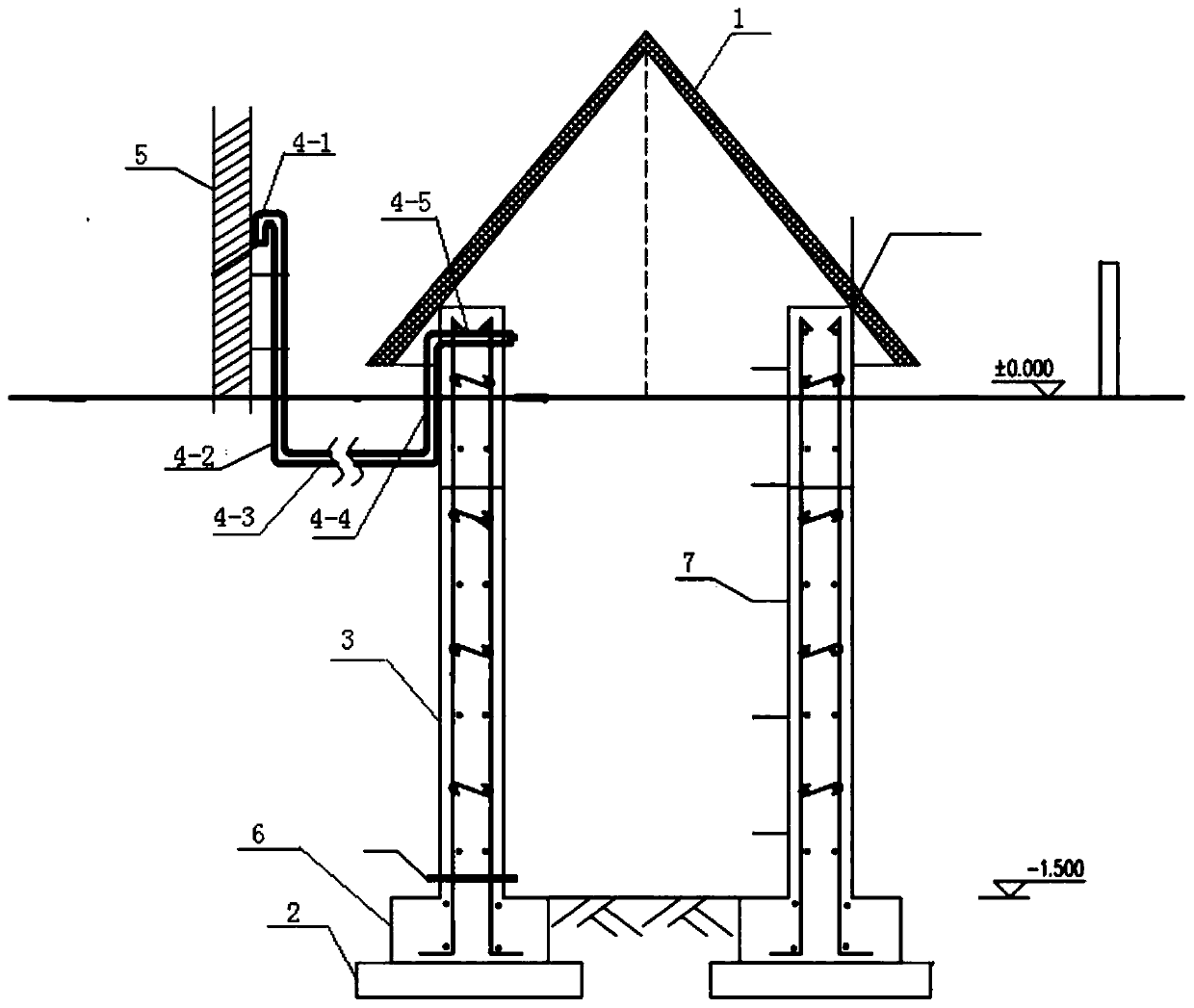

[0035] Embodiment 1, a construction method for a battery well according to the embodiment of the present invention, comprising:

[0036] Step 1, fixing the base 2 in the foundation pit below the ground inside the well body.

[0037] In the above step 1, the base 2 can be placed in the soil layer in the foundation pit, and the part above the base 2 in the foundation pit is backfilled with plain soil layered and compacted, and the plain soil is backfilled on the opposite sides and surroundings of the two bases 2 at the same time . At this time, the layered thickness of plain soil backfill shall not be greater than 300mm, and the compaction coefficient shall not be less than 0.94. Plain soil is natural sedimentary soil that is not doped with other impurities, has a fine and uniform density, and has a certain viscosity. After backfilling with plain soil, the surroundings of the base 2 are made more compact.

[0038] In the above step 1, when there is a backfill soil layer on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com