car brake caliper

A technology of automobile brakes and brake seats, which is applied in the direction of brake types, brake components, brake actuators, etc., and can solve problems such as hydraulic oil leakage and brake block wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

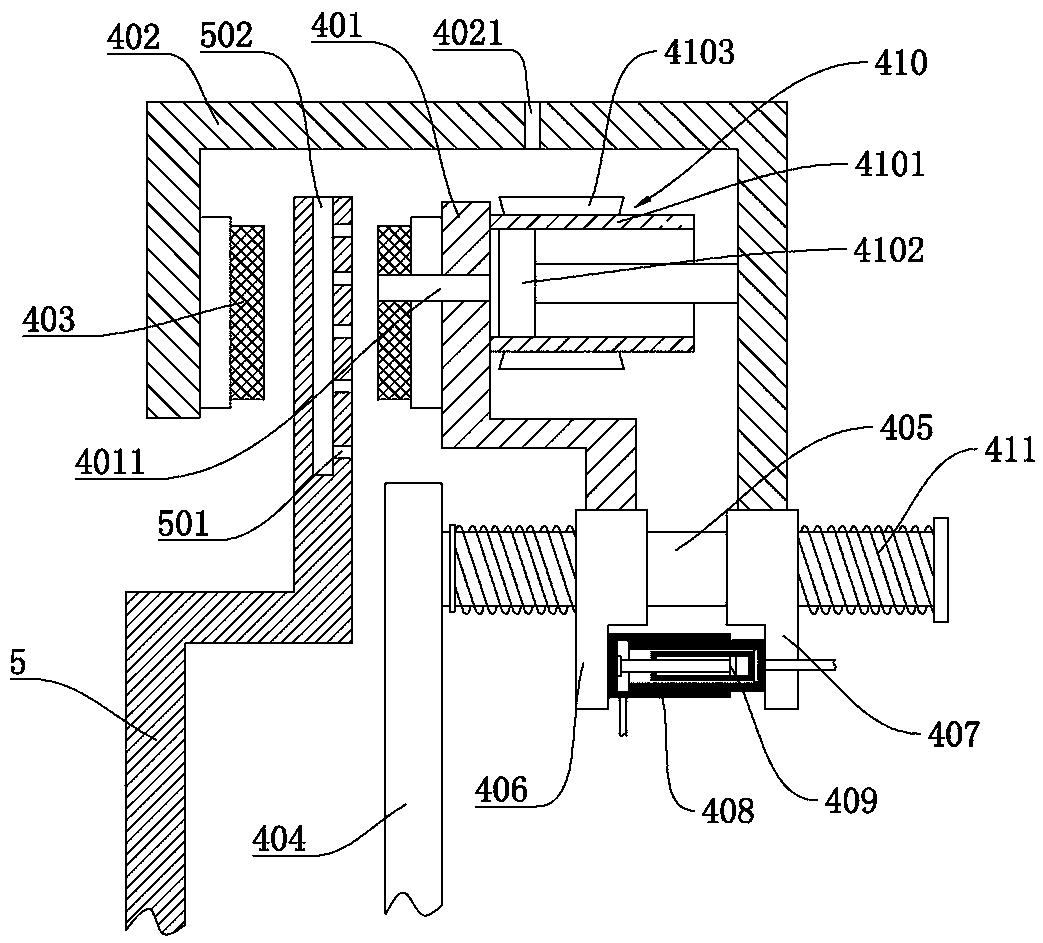

[0017] Example: such as figure 1 with figure 2 As shown, an automobile brake caliper used for braking the brake disc 5 includes a brake bracket 404, a first brake seat 401, a second brake seat 402, a brake block 403 and a hydraulic component 409, The brake bracket 404 is provided with a guide frame 405, the first brake seat 401 and the second brake seat 402 are slidably mounted on the guide frame 405, and the first brake seat 401 is arranged at The inner side of the brake disc 5 is connected to the brake block 403 on the same side, the second brake seat 402 is arranged on the inner side of the first brake seat 401, and the upper end of the second brake seat 402 is from The first brake seat 401 extends to the outside of the brake disc 5 and is connected to the brake blocks 403 located outside the brake disc 5 so that two brake blocks 403 are located on both sides of the brake disc 5.

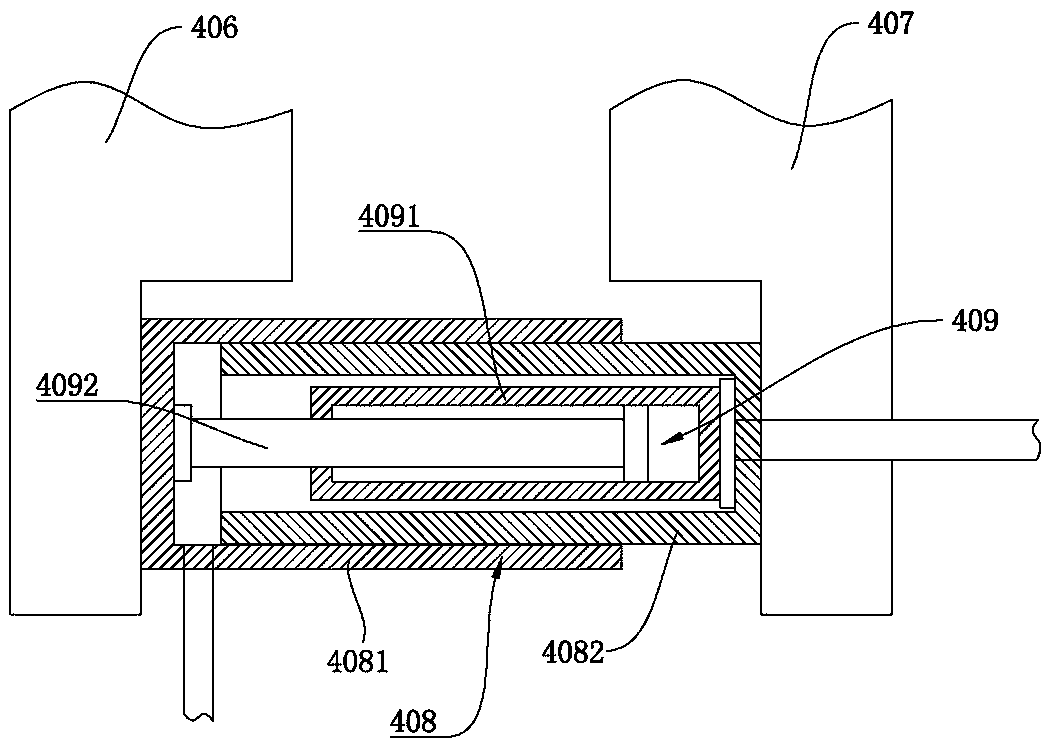

[0018] The hydraulic component 409 is connected between the first brake seat 401 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com