Power device for automatic chuck of lathe

An automatic chuck and power device technology, which is applied in the direction of drive devices, chucks, metal processing machinery parts, etc., can solve the problems of weak anti-interference ability and the influence of spindle rotation accuracy, and achieve simple and reliable structure, meet the requirements of process implementation, The effect of ensuring the rotation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

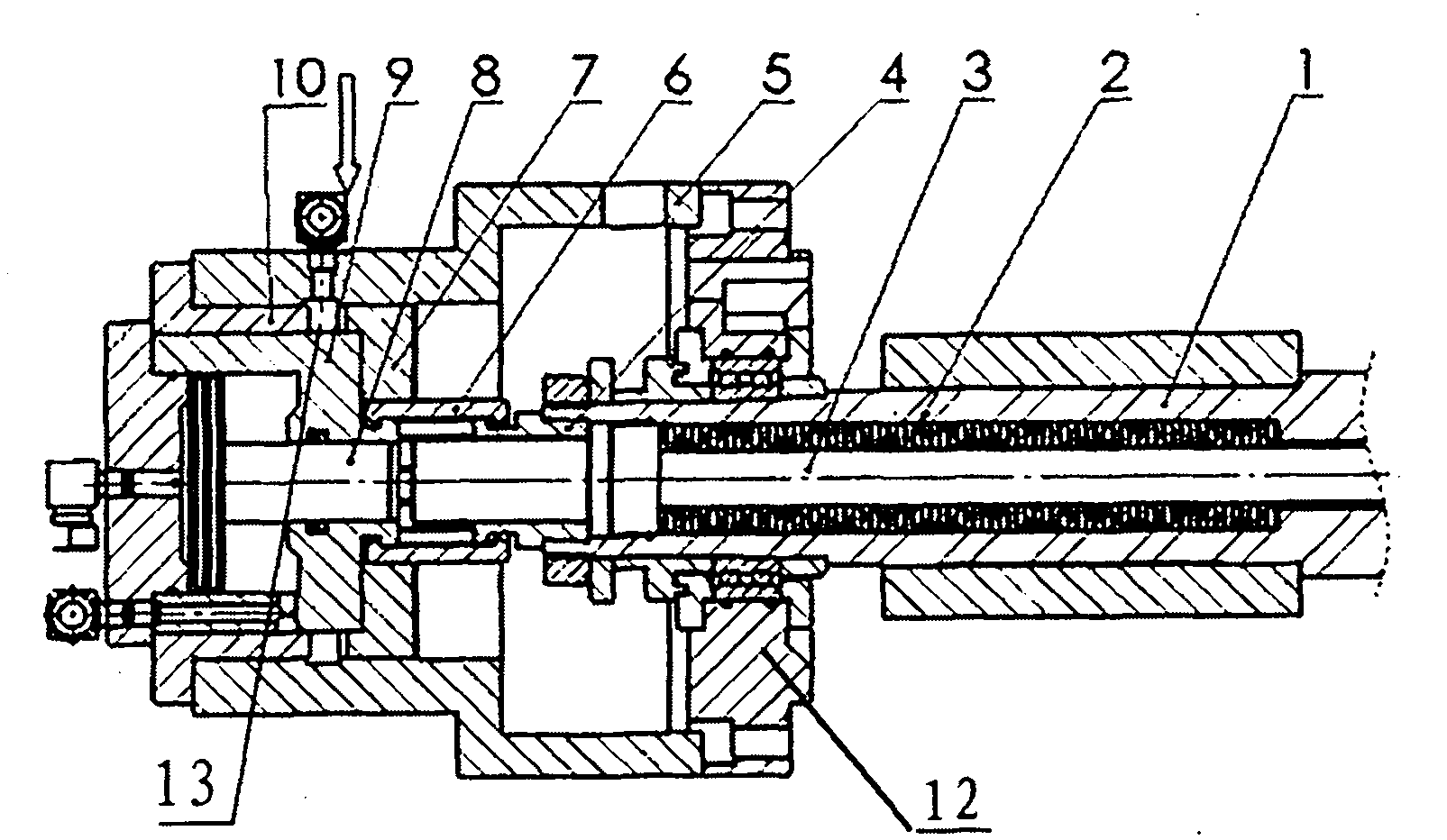

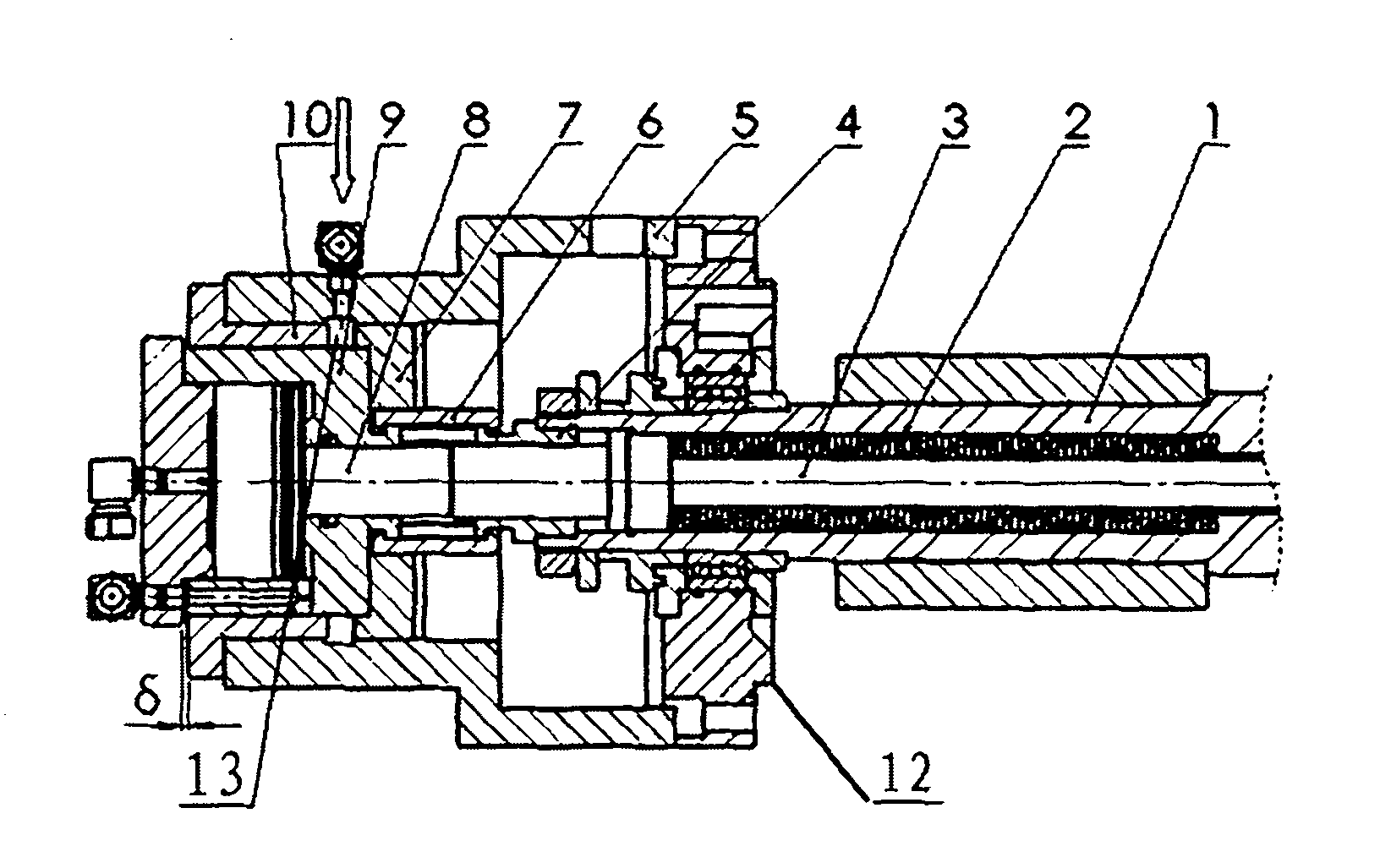

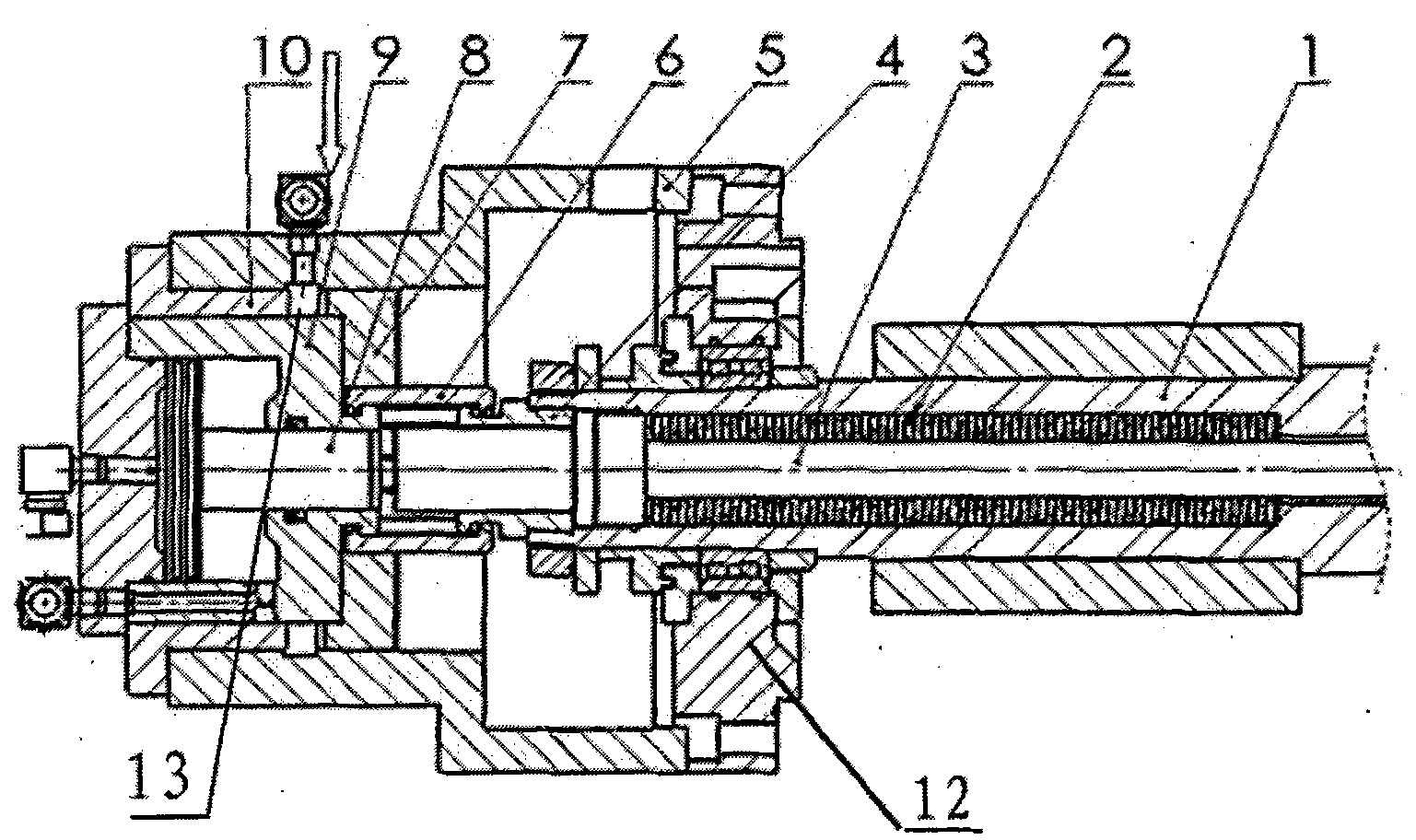

[0024] refer to figure 1 and figure 2 , a kind of power unit that is used for lathe automatic chuck of the present invention comprises headstock 12; Hollow main shaft 1, and it is installed in the headstock 12, and its front end is in order to connect machine tool chuck; Belleville spring 2, it is installed in In the hollow main shaft 1; the chuck ejector rod 3 is fixed in the hollow main shaft 1 by the butterfly spring 2. When it is pushed forward, the chuck of the machine tool can be opened to unload the workpiece. When it is retracted, the chuck of the machine tool can be closed. It is used to clamp the workpiece; the reverse buckle ring 4 is fixed on the rear end of the hollow spindle 1; the claw 6 is buckled at the end of the reverse buckle ring 4 and can float with a certain gap relative to the reverse buckle ring 4. When the claw 6 It can be engaged with each other and fastened when it moves in the opposite direction with the reverse buckle ring 4; the front end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com