Architectural engineering construction on-site protective shed

A construction site and construction engineering technology, applied in the direction of buildings, small buildings, building types, etc., can solve the problems of limited gravity bearing capacity of protective sheds, project losses, and easy breakdown of overhead protection, etc., to achieve sensitive sliding response and structural The damage reduction and the effect of reducing the interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

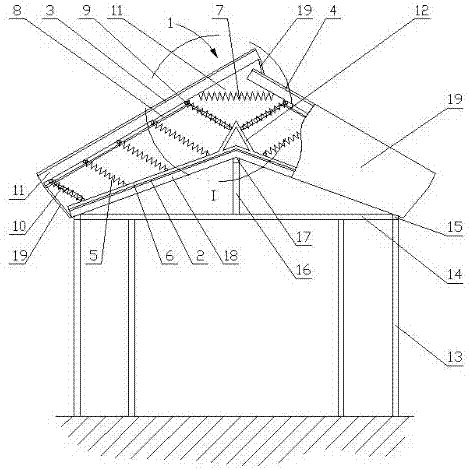

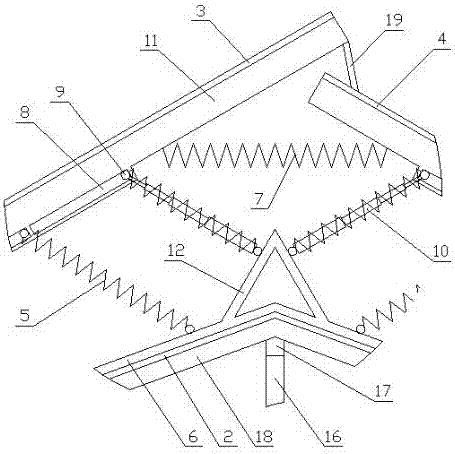

[0019] Such as figure 1 As shown, the present embodiment is a construction site protective shed, including a steel structure support, the steel structure support is provided with an inlet and outlet, the top of the steel structure support is provided with a top protection structure, and the top protection structure includes a structure fixedly connected to the steel structure support. The two-slope top-type fixed protection layer 2, the upper side of the fixed protection layer 2 is provided with an unloading structure 1; the unloading structure 1 includes a movable plate 3 and a movable plate 2 respectively corresponding to the two slopes of the fixed protective layer 2 , the slope of movable plate one 3 and movable plate two 4 is greater than the slope of fixed protection layer 2, and the upper end of movable plate one 3 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com