Fault water outburst and mud outburst simulation equipment and test method

A technology for simulating equipment and faults, applied in the field of underground engineering and geotechnical engineering test instruments, can solve the problems of loose and broken medium, serious disaster consequences, complex mechanical properties, etc., to achieve protection from damage, improve service life, and good force transmission effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

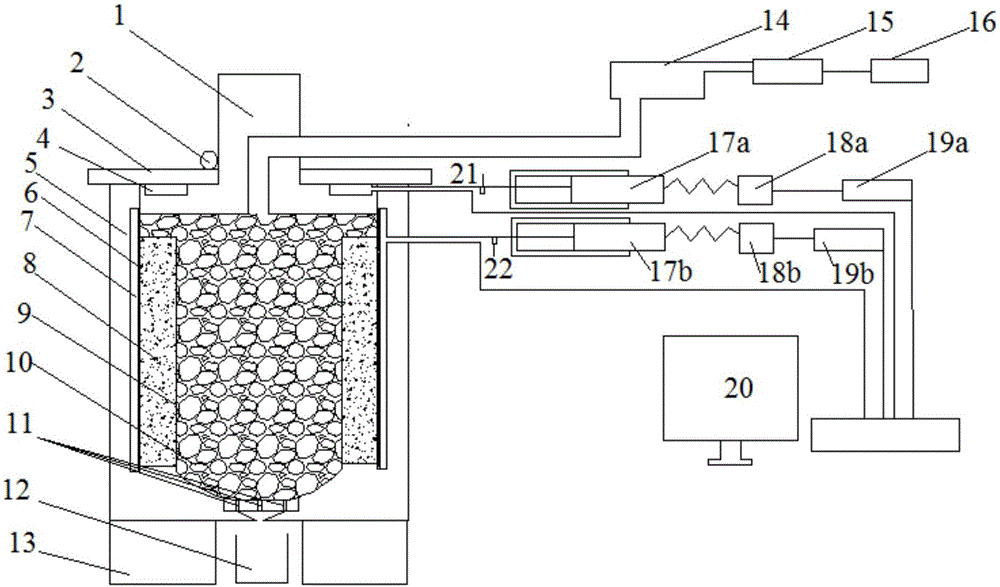

[0058] A simulation equipment for fault water and mud inrush, such as figure 1 Shown. This test instrument includes: composite pressure chamber 9 (composed of elastic rubber sleeve 6, loading cover 1, prefabricated fault mold 8, sample 10, water inrush mud plate 11), axial pressure servo control system (consisting of axial pressure sensor 21. Data acquisition and control system 20, axial compression servo loading system 17a, axial compression servo motor 18a, axial compression loading pump 19a), confining pressure servo control system (consisting of confining pressure stress sensor 22, data collection and control system 20, Confining pressure servo loading system 17b, confining pressure servo motor 18b, confining pressure loading pump 19b), water pressure control system (composed of water storage regulator connector 14, water pressure control system 15, water pressure loading pump 16, data acquisition It is composed of the control system 20), the muddy water collector 12 and ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com