Clamping tool for hydraulic pipes

A technology for clamping tooling and hydraulic pipes, which is applied in the direction of pipeline supports, pipes/pipe joints/pipes, mechanical equipment, etc. The effect of installation or disassembly, reducing metal fatigue and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

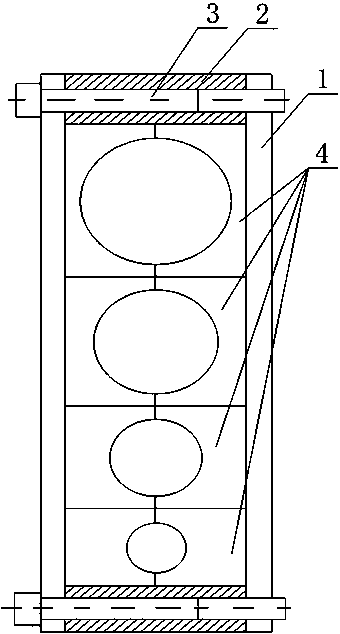

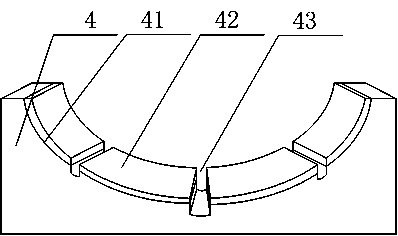

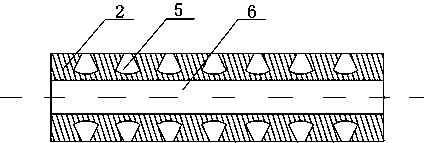

[0021] Such as figure 1 , figure 2 and image 3 As shown, the present embodiment includes two side plates 1 arranged in parallel, and the ends of the two side plates 1 are connected by bolts 3, and multiple A clamping block 4 is provided with a semicircular clamping surface 41 at the end of the clamping block 4, and a plurality of rectangular grooves 43 are formed on the clamping surface 41, and a plurality of rectangular grooves 43 The clamping surface 41 is divided into a plurality of independent circular arc segments, and elastic pads 42 are installed on the circular arc segments, and the two opposing clamping blocks 4 merge to form a closed circular clamp holding ring, and the diameters of a plurality of the circular holding rings are not the same, and also include two fastening plates 2, the middle part of the fastening plate 2 has a threaded hole 6 for the bolt 3 to pass through, in the A plurality of telescopic slots 5 are formed on the outer peripheral wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com