Dustproof ceramic body drying device

A technology of drying device and ceramic body, which is applied in the direction of ceramic product drying, drying, drying machine, etc., which can solve the problems of product cracking, heavy labor, reducing product production efficiency and pass rate, etc., and achieve uniform drying Good effect, avoid excessive drying, good effect of dust prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

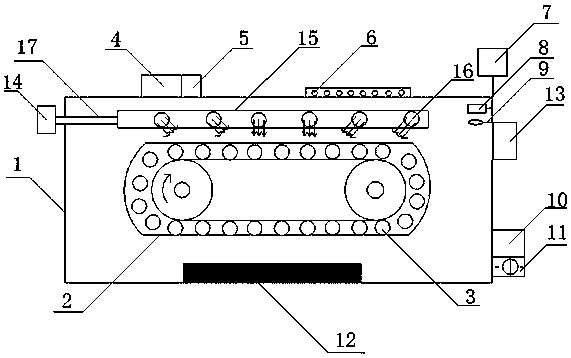

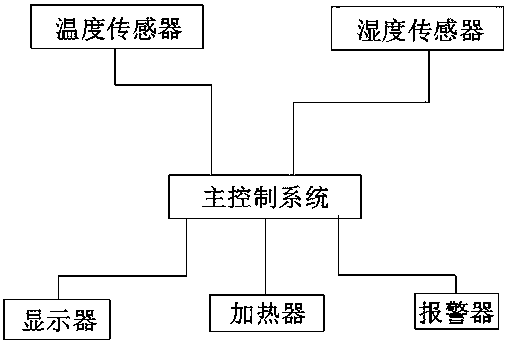

[0026] Such as figure 1 , 2 As shown, a dust-proof ceramic green body drying device includes a drying box 1 and an endless conveyor chain 2, the endless conveyor chain 2 is arranged inside the drying box 1, and the annular conveyor chain 2 is provided with a ceramic cup holder 3, and the oven The top of the drying box 1 is provided with a transmission control box 4, a ventilation hole 6 and an alarm 7, a display 10 is provided on one side of the drying box 1, a time regulator 11 is provided at the bottom of the display 10, and a side of the inner cavity of the drying box 1 is provided. There are temperature sensor 8 and humidity sensor 9, the temperature sensor 8 and the humidity sensor 9 are electrically connected with the main control system 13, the bottom of the inner cavity of the drying box 1 is provided with a heater 12, and the top of the endless conveyor chain 2 is provided with a dust removal device. It includes a warm air preparation machine 14 and a dustproof pipe ...

Embodiment 2

[0030] Such as figure 1 , 2 As shown, a dust-proof ceramic green body drying device includes a drying box 1 and an endless conveyor chain 2, the endless conveyor chain 2 is arranged inside the drying box 1, and the annular conveyor chain 2 is provided with a ceramic cup holder 3, and the oven The top of the drying box 1 is provided with a transmission control box 4, a ventilation hole 6 and an alarm 7, a display 10 is provided on one side of the drying box 1, a time regulator 11 is provided at the bottom of the display 10, and a side of the inner cavity of the drying box 1 is provided. There are temperature sensor 8 and humidity sensor 9, the temperature sensor 8 and the humidity sensor 9 are electrically connected with the main control system 13, the bottom of the inner cavity of the drying box 1 is provided with a heater 12, and the top of the endless conveyor chain 2 is provided with a dust removal device. It includes a warm air preparation machine 14 and a dustproof pipe ...

Embodiment 3

[0036] Such as figure 1 , 2 As shown, a dust-proof ceramic green body drying device includes a drying box 1 and an endless conveyor chain 2, the endless conveyor chain 2 is arranged inside the drying box 1, and the annular conveyor chain 2 is provided with a ceramic cup holder 3, and the oven The top of the drying box 1 is provided with a transmission control box 4, a ventilation hole 6 and an alarm 7, a display 10 is provided on one side of the drying box 1, a time regulator 11 is provided at the bottom of the display 10, and a side of the inner cavity of the drying box 1 is provided. There are temperature sensor 8 and humidity sensor 9, the temperature sensor 8 and the humidity sensor 9 are electrically connected with the main control system 13, the bottom of the inner cavity of the drying box 1 is provided with a heater 12, and the top of the endless conveyor chain 2 is provided with a dust removal device. It includes a warm air preparation machine 14 and a dust-proof pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com