Storage detection method for food safety stock based on data processing

A detection method and food safety technology, applied in the field of food safety inventory storage detection, can solve the problems affecting the safety and reliability of food storage work, inability to discover food in time, and food deterioration, etc., to achieve easy tracking management, strong operability, The effect of preventing food quality from being affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

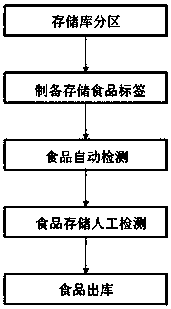

[0018] like figure 1 A kind of food safety stock storage detection method shown comprises the following steps:

[0019] The first step is to partition the storage warehouse. First, divide the storage area according to the type of food stored, and divide it into freezing area, low temperature area, and normal temperature area according to the storage temperature environment, and divide it into animal storage area and vegetable storage area according to the product type. storage area, fermented food storage area, puffed food storage area and non-fermented food storage area, and at least one animal storage area, plant storage area, fermented food storage area, puffed food storage area and non-fermented food storage area, and They are respectively distributed in the freezing area, low temperature area, and normal temperature area, and each storage area is separated by aisles. In the divided storage areas, there are storage terminals and withdrawal terminals, and the storage termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com