Combined storage bin capable of automatically dropping commodities and automatic vending machine with combined storage bins

A technology for storage bins and vending machines, which is applied to coin-free or similar appliances, counting mechanisms/items, coin-operated equipment for distributing discrete items, etc. Goods and one-time settlement and other issues, to achieve efficient network maintenance and management, improve space utilization, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

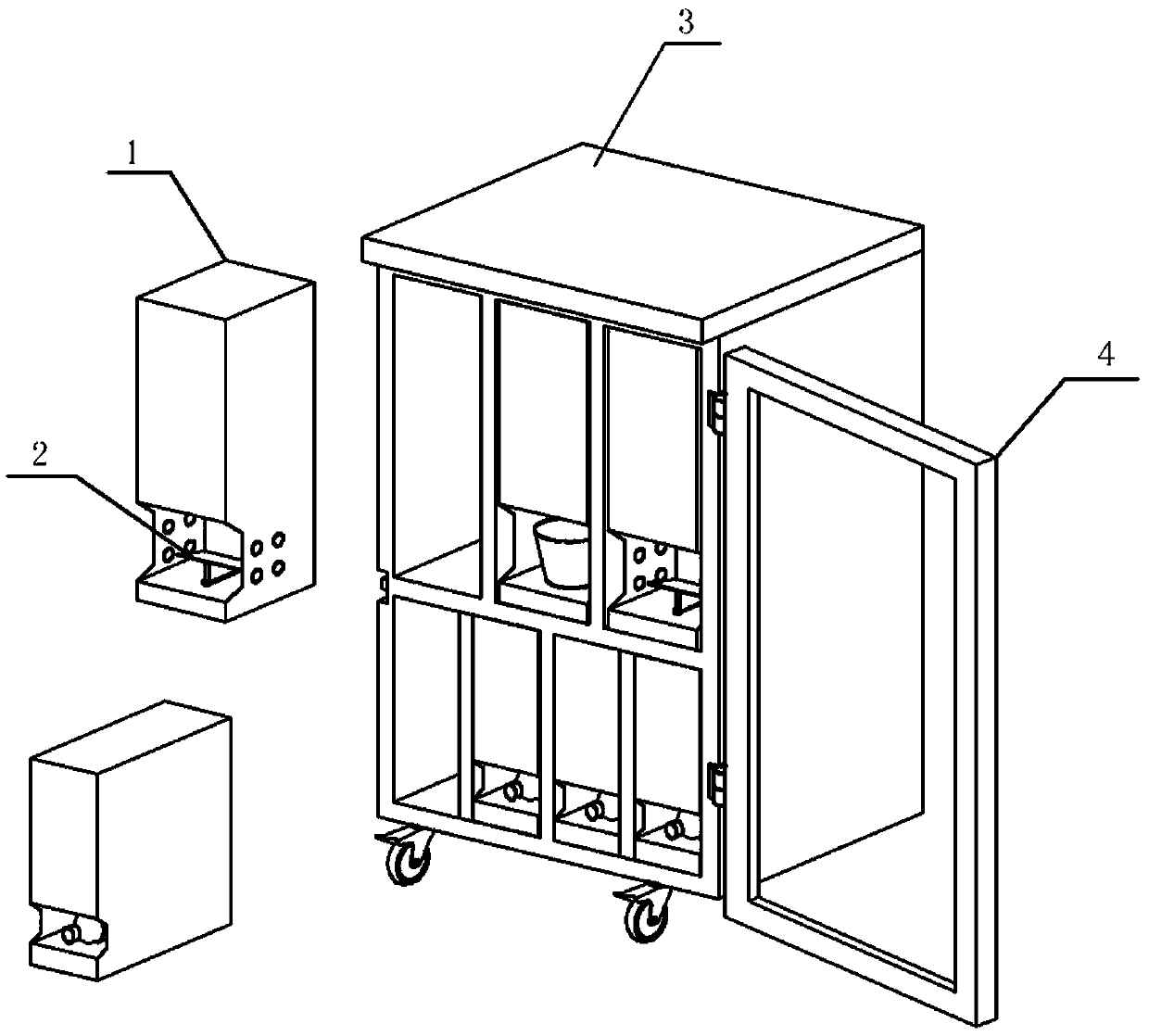

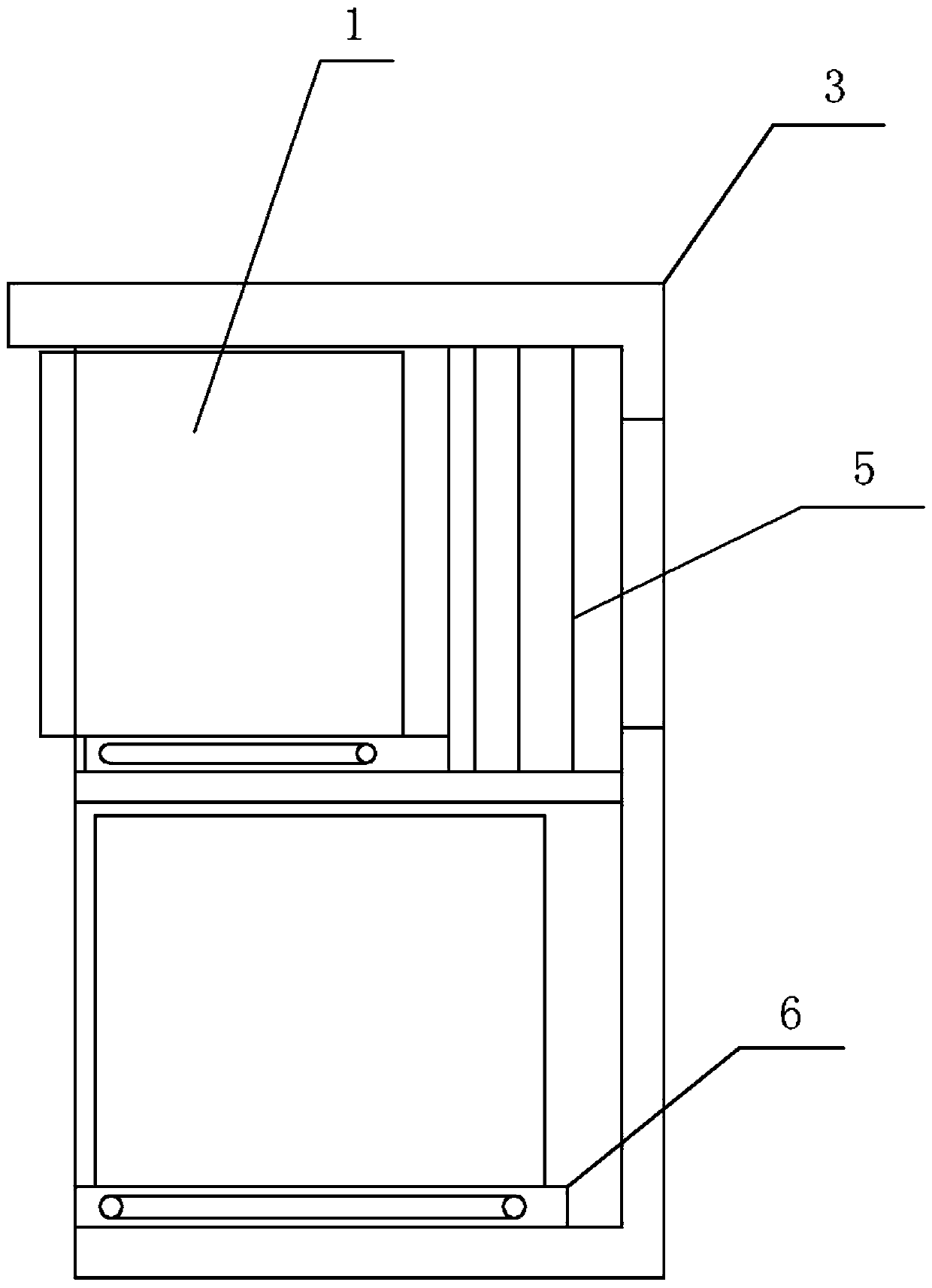

[0034] A combined storage bin for automatic unloading in this embodiment includes a rectangular hollow-structured bin body 1, in which goods are stacked vertically, and an opening C for a single cargo to drop out is provided at the bottom of the bin body 1 , cutting off part of the structure on both sides of the opening C to form a pick-up groove structure, and the pick-up groove is convenient for the user to take out the goods. And count by being arranged on the counter 2 that bottom is provided with in bin body 1 when goods fall out. The bin body 1 is formed by shearing, stamping and welding processes of sheet metal. The specifications of the warehouse body 1 are designed according to the external dimensions of the commodities sold and the quantity to be stacked. Each warehouse 1 stores a single type of goods, and the size of the opening C is equivalent to the specifications of the goods for sale in the warehouse 1 with a slight margin, which is convenient for taking out th...

Embodiment 2

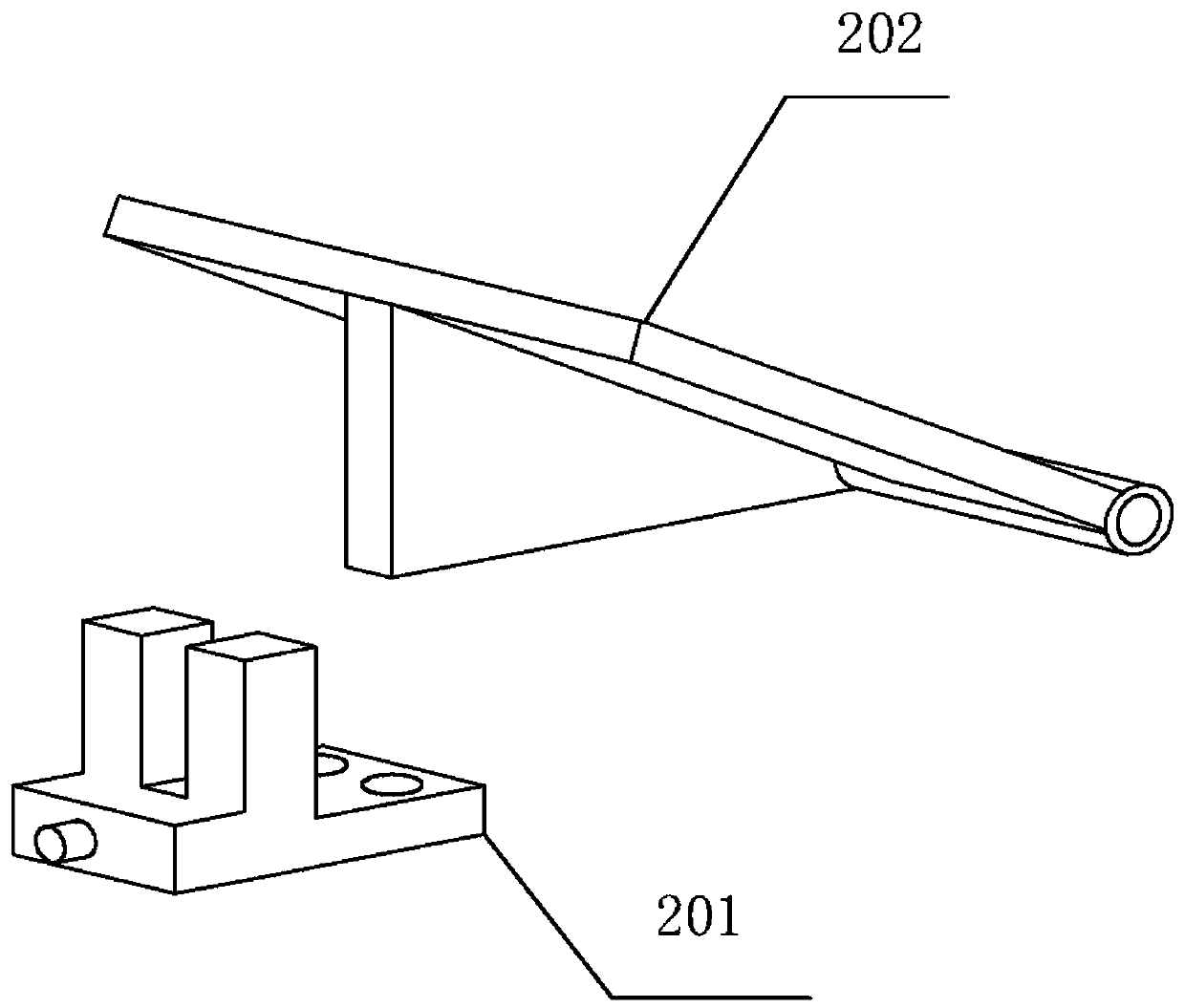

[0037] This embodiment is further defined on the basis of the above embodiments, as image 3 As shown, the counter 2 includes a photoelectric sensor 201 arranged at the bottom of the bin body 1 and a pressure plate 202 with elastic restoring force. The optical path is blocked in the groove of the sensor 201 to realize counting. Here, the counter 2 is optimized and defined, wherein the pressure plate 202 is a structure used to contact the goods and move downward under pressure. The elastic recovery force means that the pressure plate 202 has elastic potential energy, and the elasticity is provided by springs or elastic materials. Restoring force, so that the pressing plate 202 can quickly rebound upwards and activate the photoelectric sensor 201 without being pressed. The photoelectric sensor 201 is a sensor using a photoelectric element as a detection element. It first converts the measured change into a change of an optical signal, and then further converts the optical signa...

Embodiment 3

[0039] This embodiment is further defined on the basis of the above embodiments, one side of the pressing plate 202 is hinged to the inner wall of the bin body 1 so that the pressing plate 202 can rotate around its hinged side, and a torsion spring is provided at the hinge to provide elasticity. Restoration force; the raised portion on the pressing plate 202 is a blocking strip perpendicular to the pressing plate 202 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap