Heat sink module and manufacturing method thereof

A technology of a heat dissipation module and a manufacturing method, which is applied in cooling/ventilation/heating renovation, heat exchange equipment, heat exchanger fixing, etc., and can solve problems such as poor heat dissipation performance and insufficient heat dissipation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The detailed description and technical content of the present invention are described as follows in conjunction with the drawings. However, the drawings are only provided for reference and description, and are not used to limit the present invention.

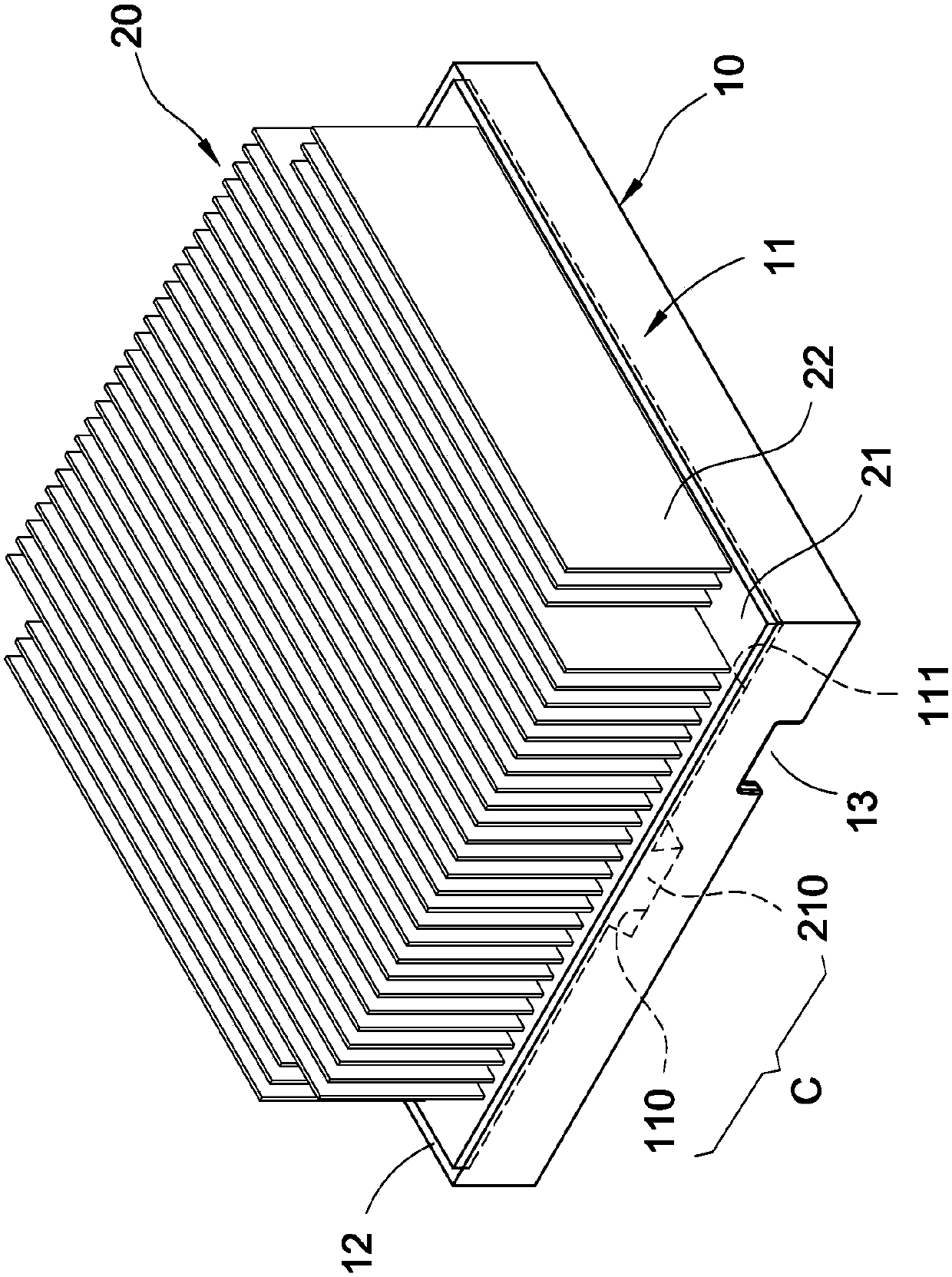

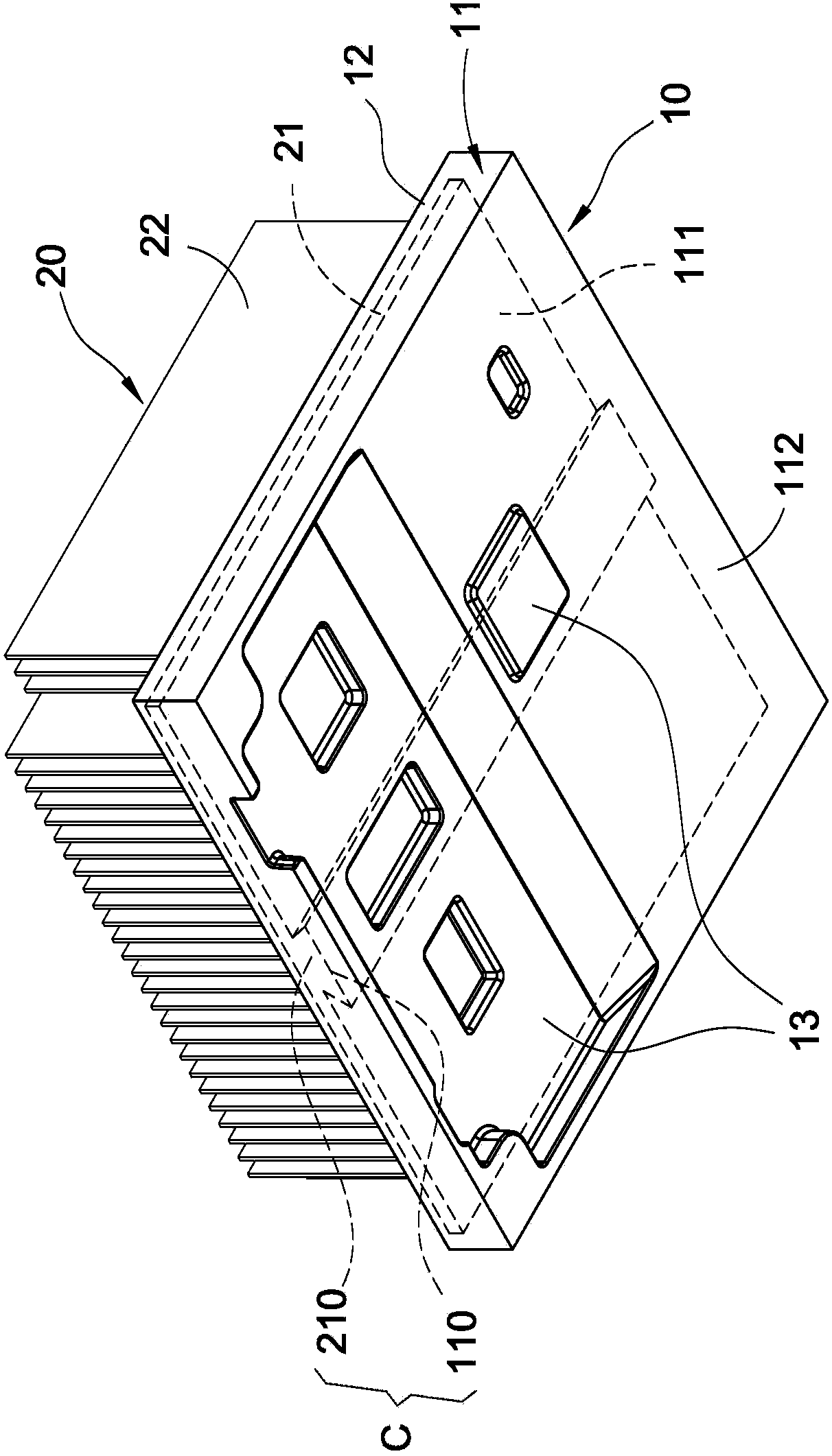

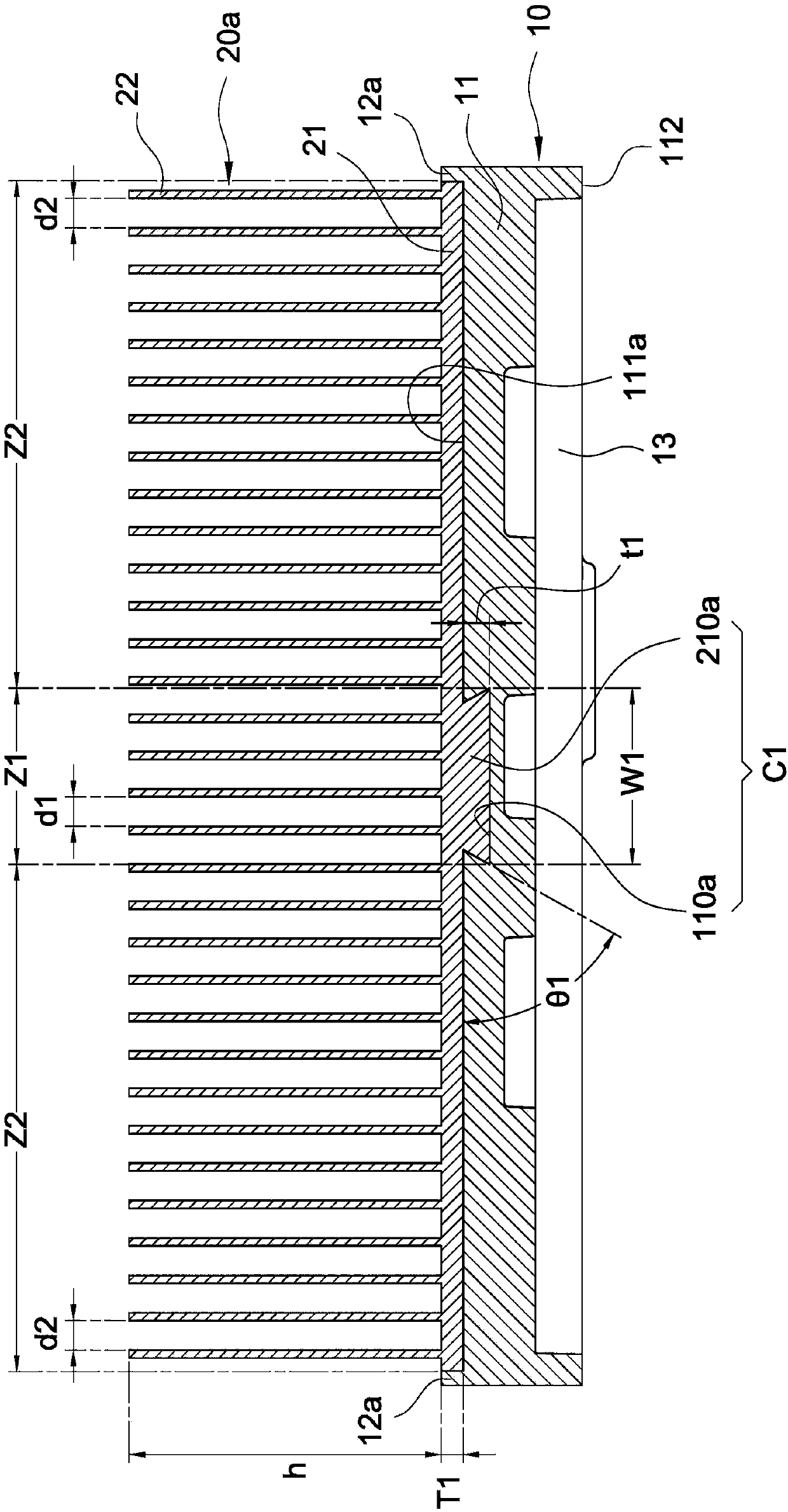

[0048] See Figure 1 to 2 versus Figure 7 As shown, the present invention provides a heat dissipation module and a manufacturing method thereof, and the following will use the manufacturing method to assist in explaining multiple implementation aspects of the formed heat dissipation module. The manufacturing method of the heat dissipation module of the present invention includes the following steps:

[0049] Step S1: A heat dissipation fin set 20 is formed by an aluminum extrusion process, wherein the heat dissipation fin set 20 includes a plate body 21, a plurality of fins 22 extending from one side of the plate body 21 and arranged at intervals, and formed on the plate A joint 210 on the other side of the body 21;

[0050] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com