Stamping mould

A stamping die and template technology, which is applied in the field of molds, can solve the problems of extending the distance between the operator's body and the press, affecting the quality and efficiency of operation, and increasing the burden on the collection basket, so as to ensure the comfort of operation, facilitate transportation and storage, The effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

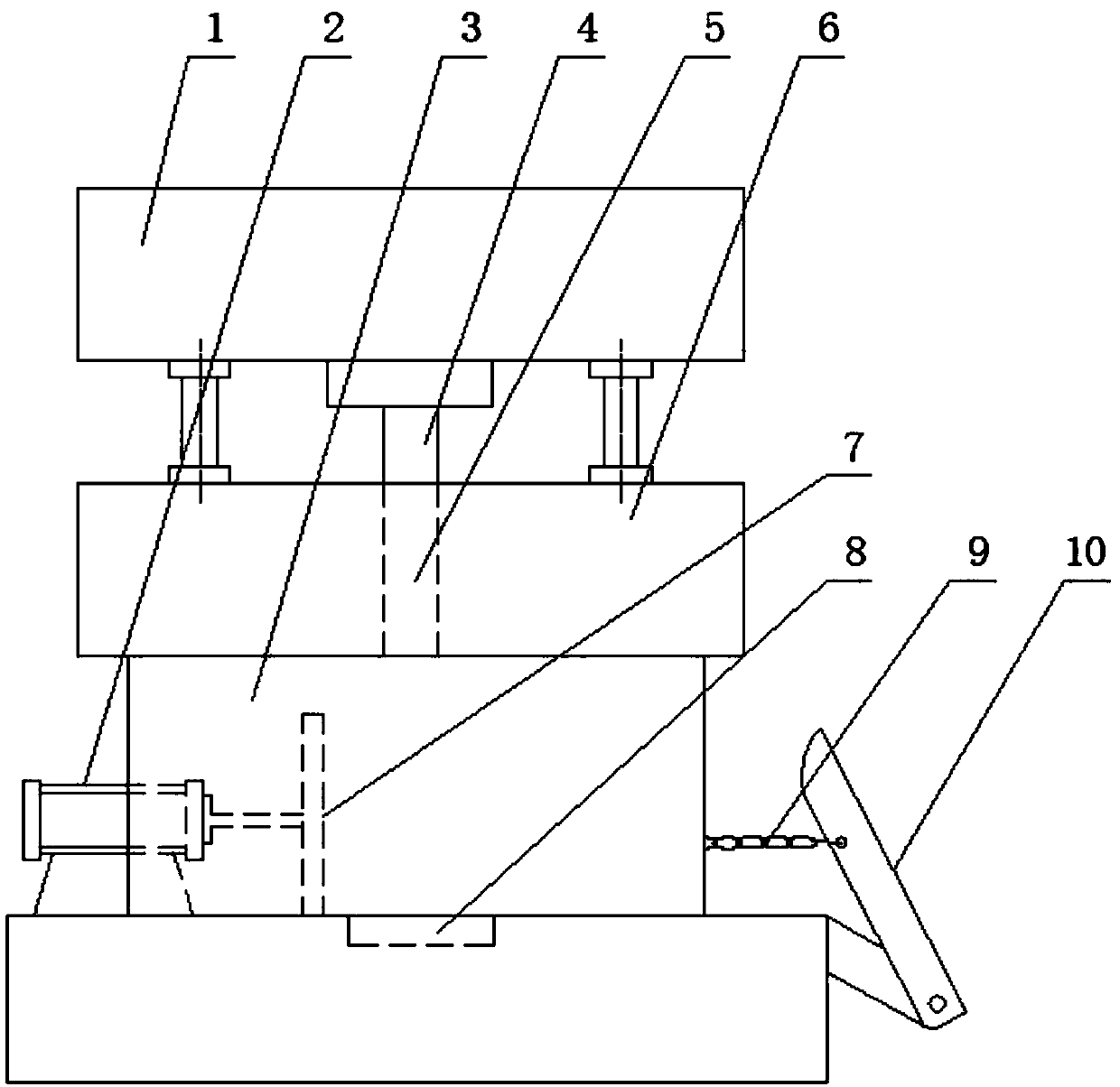

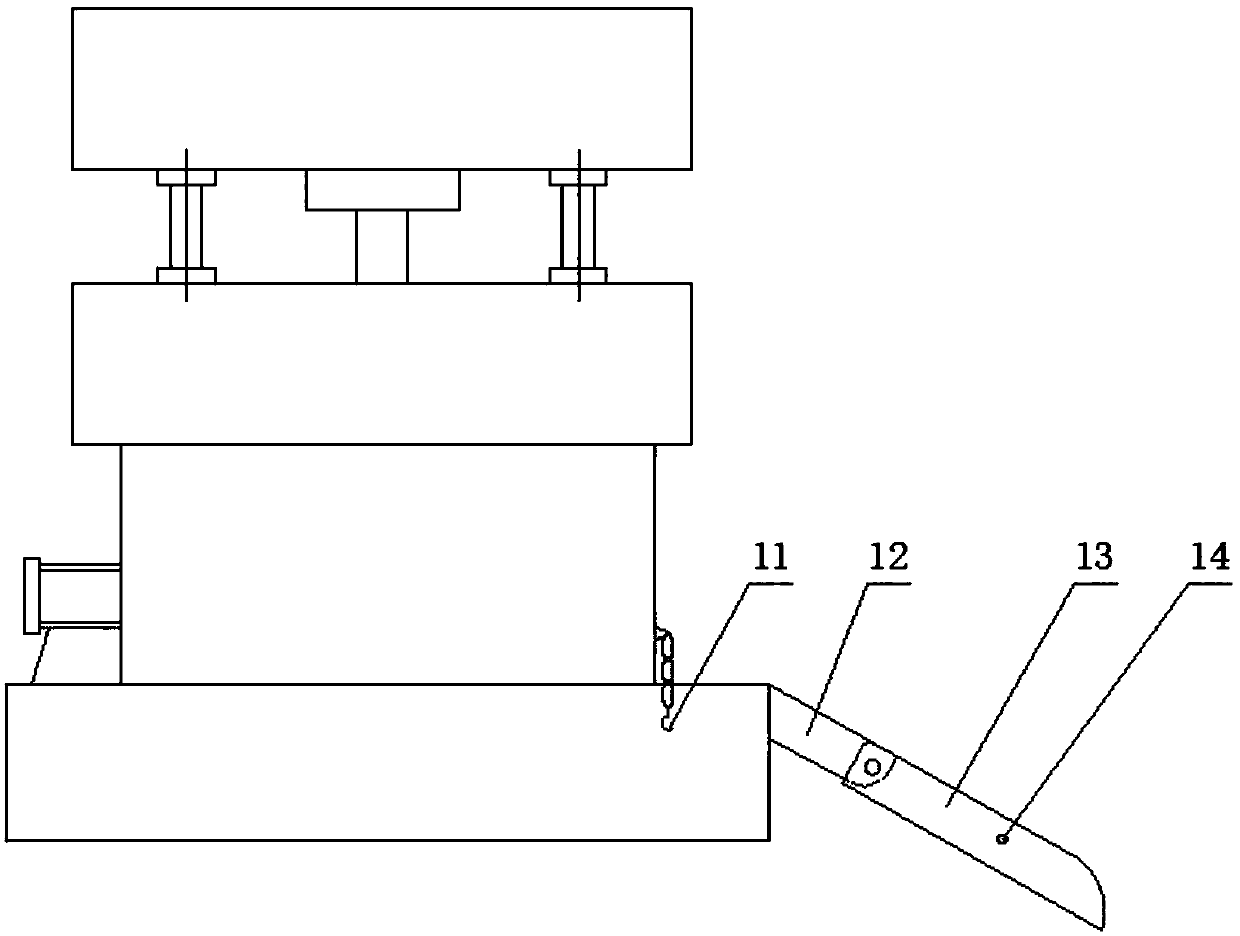

[0021] A stamping die, comprising an upper formwork 1, a lower formwork 6, a punch 4 and a base 3, the upper formwork and the lower formwork are relatively arranged up and down, a punch is arranged on the upper formwork, and the corresponding position of the punch is on the lower formwork There is a material leakage hole 5, and a base connected with the material leakage hole is arranged under the lower formwork. Its innovation is that it also includes a waste material exporting mechanism. The interior of the waste material is equipped with a waste material export mechanism, which is composed of a cylinder 2, a controller, a weight sensor 8 and a push plate 7. A cylinder is installed at one end of the length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com