Plastic bag cut-off device

A technology for cutting devices and plastic bags, applied in packaging, bag-making operations, transportation and packaging, etc., can solve the problem of large device footprint, avoid manual labor, reduce operating steps, and ensure production efficiency and service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

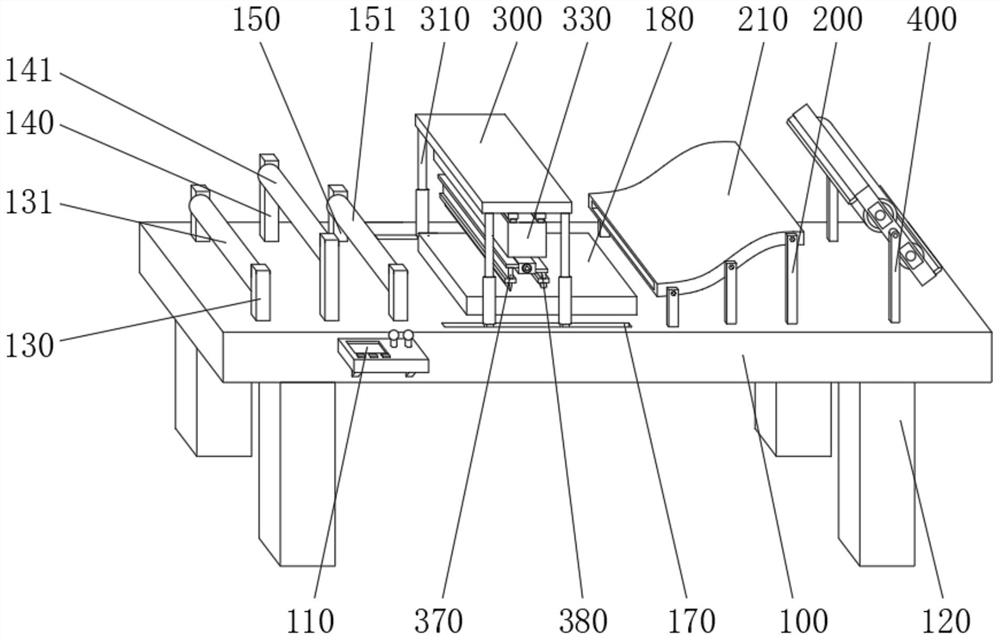

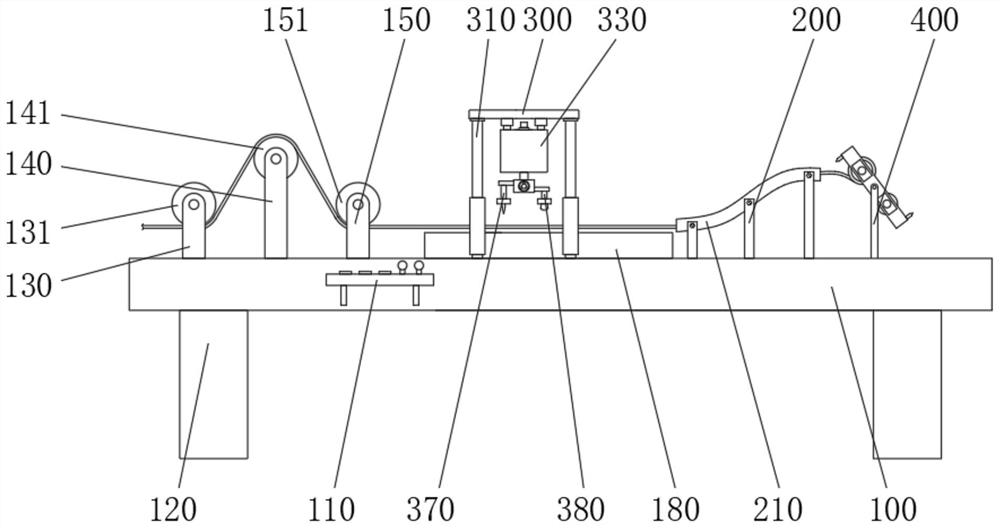

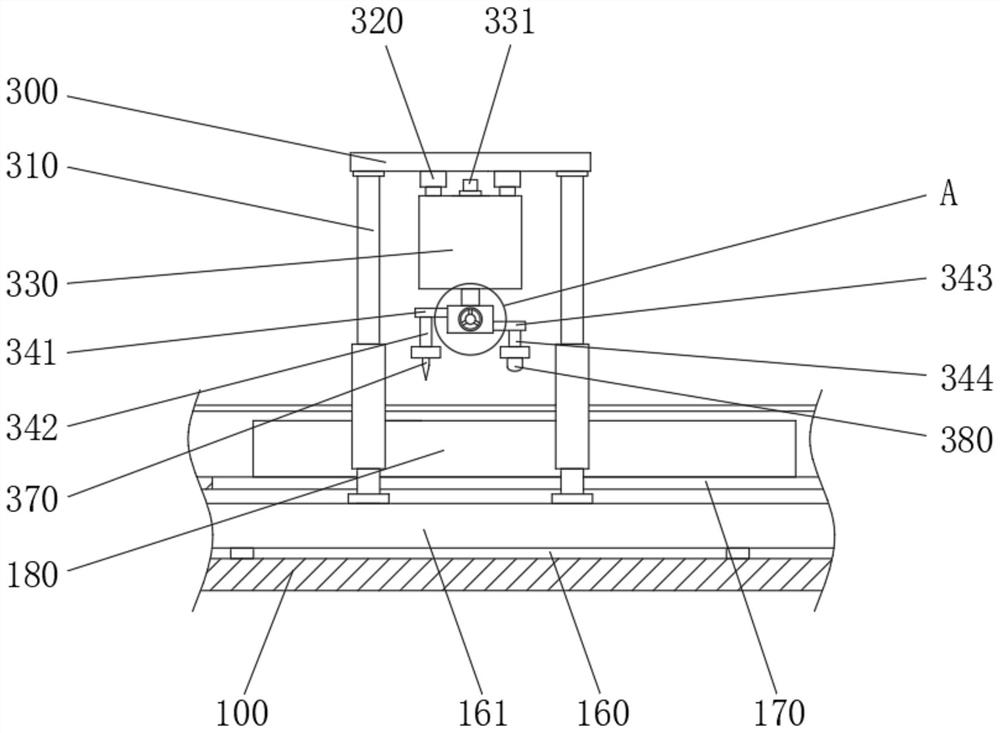

[0030] see Figure 1-2 and Figure 6-7, the present invention provides a technical solution: a plastic bag cutting device, including a base 100, two sets of fixing frames 200, a top plate 300 and two side plates 400, and the two sets of fixing frames 200 are respectively fixedly connected to the top of the base 100 On the front and rear sides, the top plate 300 is located on the left side of the two sets of fixing frames 200, and the two side plates 400 are respectively fixedly connected to the front and rear sides of the top of the base 100, and are located on the right side of the two sets of fixing frames 200, and the front of the base 100. The left side of the side wall is fixedly connected with the console 110 by bolts, the four corners of the bottom of the base 100 are welded with pillars 120, the top left side of the base 100 is fixedly connected with the first bracket 130, and the internal rotation of the first bracket 130 is connected There is a conveying roller 131,...

Embodiment 2

[0033] see Figure 1-3 and Figure 5 , the present invention provides a technical solution: a plastic bag cutting device, including a base 100, two sets of fixing frames 200, a top plate 300 and two side plates 400, and the two sets of fixing frames 200 are respectively fixedly connected to the top of the base 100 On the front and rear sides, the top plate 300 is located on the left side of the two sets of fixing frames 200, and the two side plates 400 are respectively fixedly connected to the front and rear sides of the top of the base 100, and are located on the right side of the two sets of fixing frames 200, and the front of the base 100. The left side of the side wall is fixedly connected with the console 110 by bolts, the four corners of the bottom of the base 100 are welded with pillars 120, the top left side of the base 100 is fixedly connected with the first bracket 130, and the internal rotation of the first bracket 130 is connected There is a conveying roller 131, ...

Embodiment 3

[0036] see Figure 1-4 , the present invention provides a technical solution: a plastic bag cutting device, including a base 100, two sets of fixing frames 200, a top plate 300 and two side plates 400, and the two sets of fixing frames 200 are respectively fixedly connected to the top of the base 100 On the front and rear sides, the top plate 300 is located on the left side of the two sets of fixing frames 200, and the two side plates 400 are respectively fixedly connected to the front and rear sides of the top of the base 100, and are located on the right side of the two sets of fixing frames 200, and the front of the base 100. The left side of the side wall is fixedly connected with the console 110 by bolts, the four corners of the bottom of the base 100 are welded with pillars 120, the top left side of the base 100 is fixedly connected with the first bracket 130, and the internal rotation of the first bracket 130 is connected There is a conveying roller 131, the top of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com