Pure copper conductor casting sand mold for transformer

A technology for transformers and castings, applied in the directions of casting molds, casting mold components, casting molding equipment, etc., can solve the problems that conventional sand molds cannot achieve sequential solidification, sand core gas cannot be eliminated, and sand cores are difficult to fix, and reduce slag inclusion defects. , Good internal exhaust, the effect of ensuring the quality of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

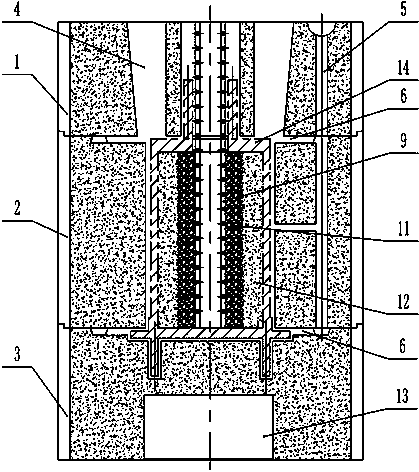

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

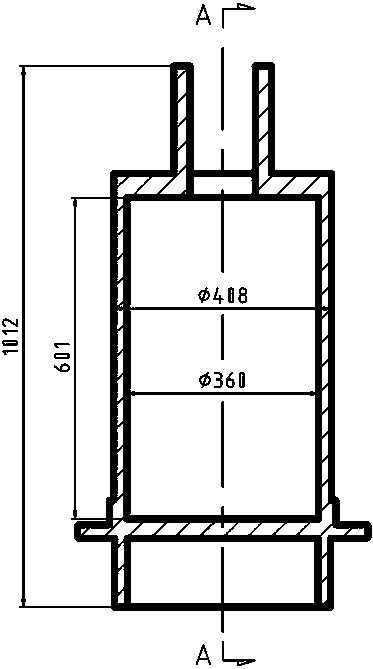

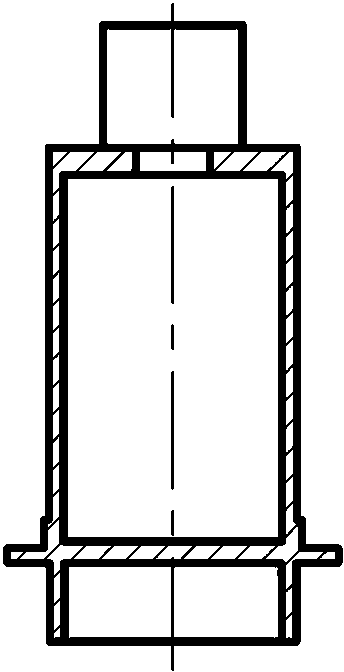

[0019] like Figure 3 to Figure 6 , is a structural schematic diagram of an embodiment of a pure copper conductor casting sand mold for a transformer in the present invention. According to the casting structure, the sand box is divided into an upper box 1, a middle box 2 and a lower box 3, and the top of the casting 14 is placed upwards and placed on the upper The box 1 is provided with a riser 4, a main runner 5 is arranged on the side parallel to the casting, and an annular secondary runner 6 is respectively arranged on the two parting surfaces.

[0020] The inside of the core is a T-shaped double-layer steel plate frame structure. Several through holes 8 and two positioning holes 15 are drilled on the steel plate 7. The core 9 is erected on the upper box 1 through two positioning rods 10 and suspended in the middle of the cavity. . Coke 11 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com