Clamp for machining planetary frame main body on horizontal machining center

A machining center and planet carrier technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of unstable processing quality, complicated operation process, long adjustment time, etc., and achieve low processing cost and adjustment. The effect of short time and stable processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

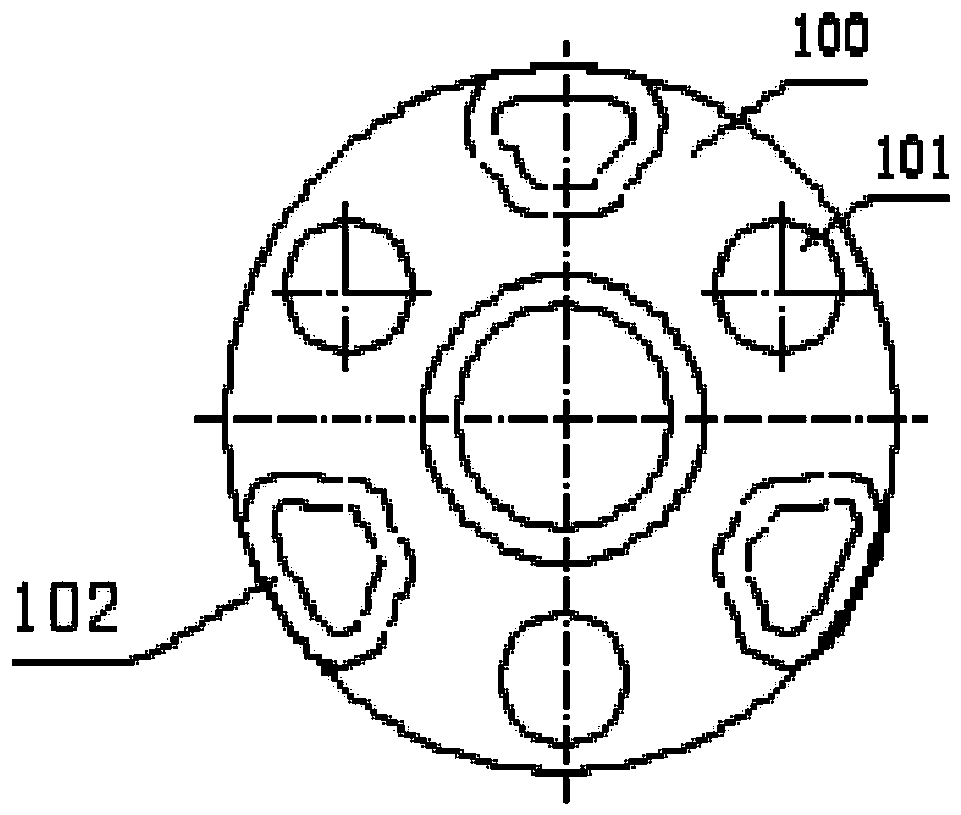

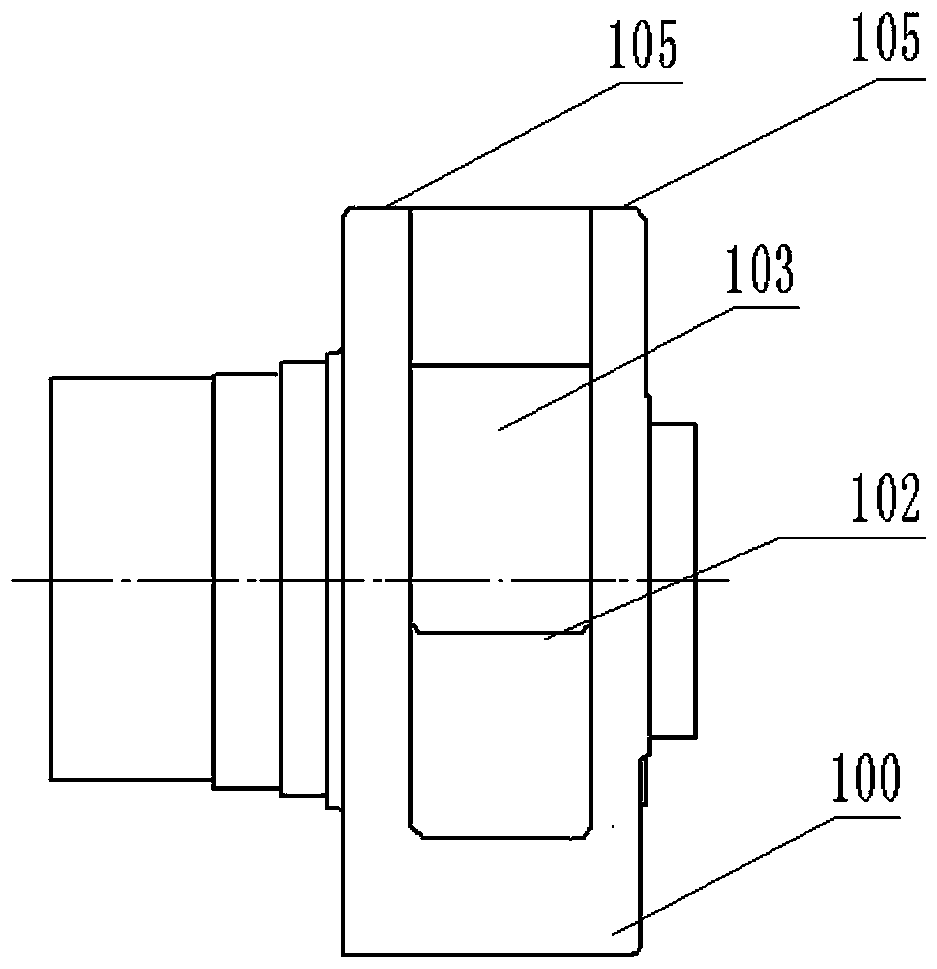

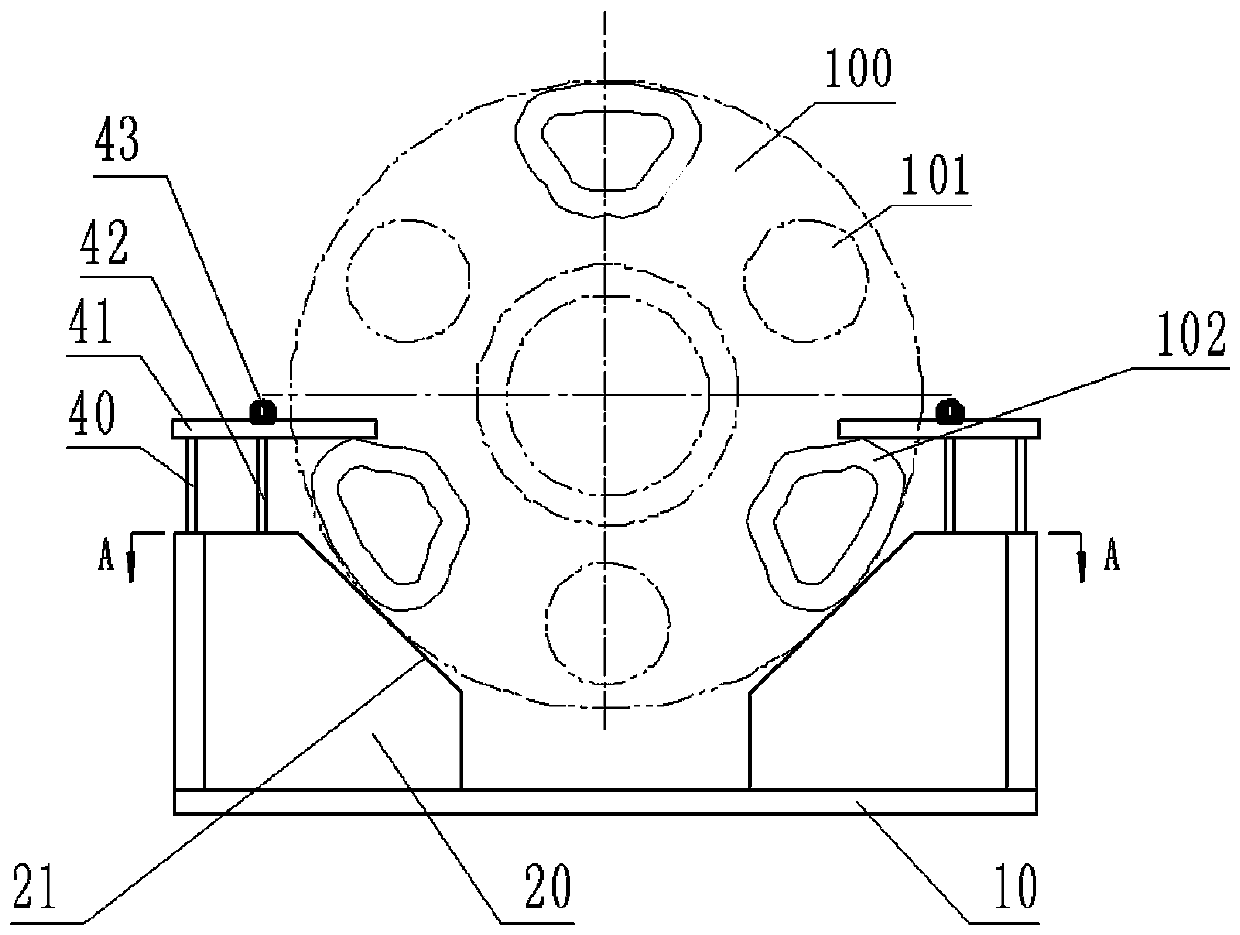

[0023] see Figure 6 to Figure 9 , the fixture of the present invention for processing the main body of the planetary carrier on the horizontal machining center includes a base plate 10, four positioning plates 20 with one angle being an inclined positioning surface 21, four support plates 30 and four each including support rods 40, Clamping parts 40, 41, 42, 43 of pressing plate 41, double-ended stud 42 and nut 43; wherein, the four positioning plates 20 and the four supporting plates 30 are all connected on the base plate 10; the four positioning plates The plates 20 are symmetrically distributed in a rectangular space, and the two positioning plates 20 at the front and rear ends are all inclined to the positioning surface 21 and correspond to the parts other than the reinforcing ribs 102 on the outer side of the planetary carrier main body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com