Camera debugging device and method

A debugging method and camera technology, applied in the field of optical inspection, can solve problems such as complicated debugging process, long cycle, difficult camera adjustment, etc., to achieve the effect of reducing workload, improving accuracy, and avoiding multiple acquisitions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

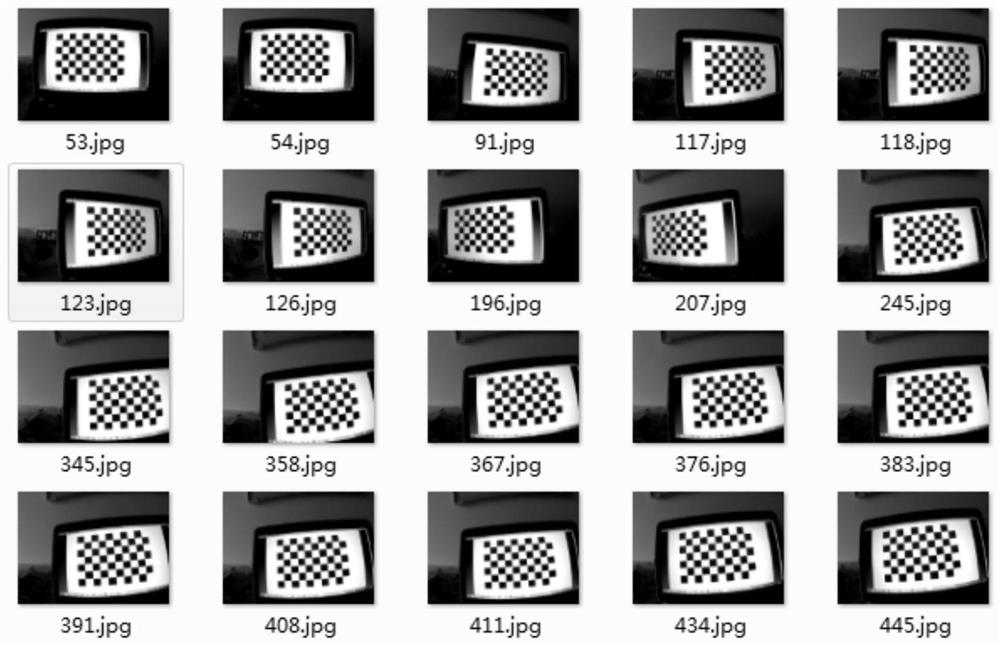

Image

Examples

Embodiment 1

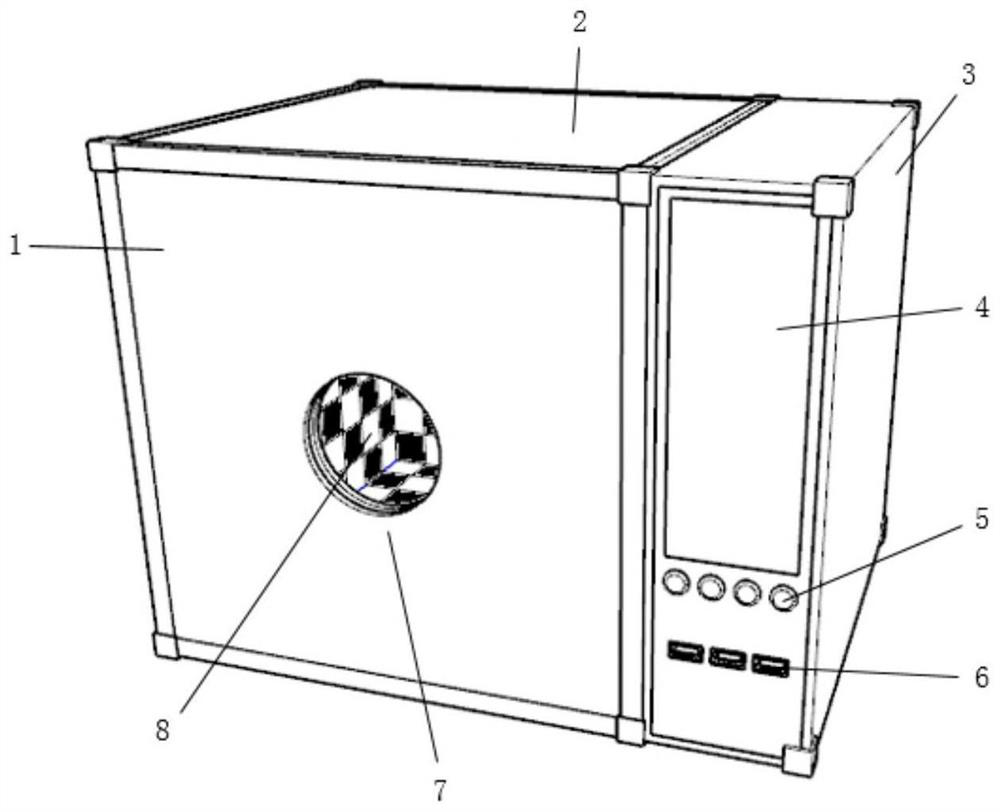

[0055]according toFigure 2-5As shown, Embodiment 1 discloses a camera debugging device for camera testing or correction. Embodiment 1 records an embodiment that only includes a light box in the camera debugging device. It should be noted that the camera in this embodiment It can be a camera in an electronic device such as a mobile phone, or can be applied to a lens in a camera. There is no specific limitation here. The debugging includes but not limited to camera testing such as imaging quality tuning test, parameter testing, and camera correction such as distortion correction.

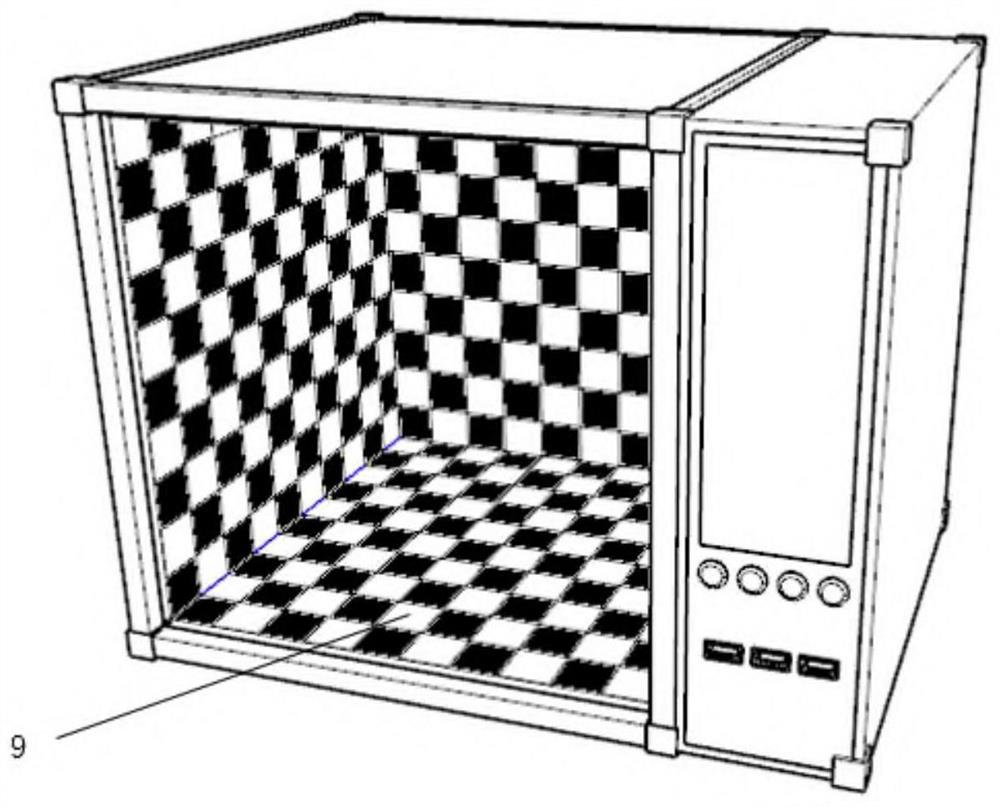

[0056]The light box includes a front cover plate 1 and a preset image display part 2. The front cover plate 1 and the preset image display part 2 are assembled together to enclose the inner space of the light box. The inner side of the preset image display part 2 is provided with a calibration pattern, Preferably, the calibration pattern occupies all the inner area of the preset image display component, so t...

Embodiment 2

[0066]SeeFigure 2-5, Embodiment 2 discloses a computing device 3 for camera debugging. The computing device 3 is a special computer designed for camera debugging. The computing device includes a circuit board, a processor, a register, a disk, a power supply, an interface, and Data bus, etc. Specifically, the computing device 3 includes a box with a display screen 4, a knob / button 5, and a data interface 6, and a processor, a register, a data bus, and other devices used for calculation and communication are arranged in the box.

[0067]Among them, the processor can be used to test or correct the camera to be debugged, and determine the test or correction result.

[0068]The display screen 4 is used to monitor the test or correction process of the camera to be debugged, and display the images collected by the camera to be debugged and the image test or correction result. The display screen 4 is preferably a touch screen to facilitate control of the test or correction process.

[0069]The multi...

Embodiment 3

[0074]See alsoFigure 2-5, Embodiment 3 discloses a camera debugging device that fixes the computing device and the light box together. The device is composed of the light box of Embodiment 1 and the computing device of Embodiment 2, wherein the light box and the computing device can be Screws or screws or glue are fixedly connected together and used in conjunction with the test analysis or correction of the camera.

[0075]When in use, the specific cooperation mode of the light box and the computing device and the realized debugging function may not be specifically limited.

[0076]Embodiment 3 of the present invention combines a light box and a computing device, can combine the calibration pattern collection process with the analysis processing process, and supports real-time adjustment of the entire test or correction process through the display screen and knob keys. It greatly reduces the workload of data transmission and transfer during collection to analysis, and greatly improves the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com