Numerical-control vertical automatic loader

An automatic feeding, numerical control vertical technology, applied in the numerical control field, can solve the problems of difficult to effectively ensure the charging accuracy, affect the quality of parts processing, low degree of automation, etc., and achieve simple structure, low manufacturing cost and low noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with implementation examples and accompanying drawings, but the protection scope of the present invention should not be limited by this.

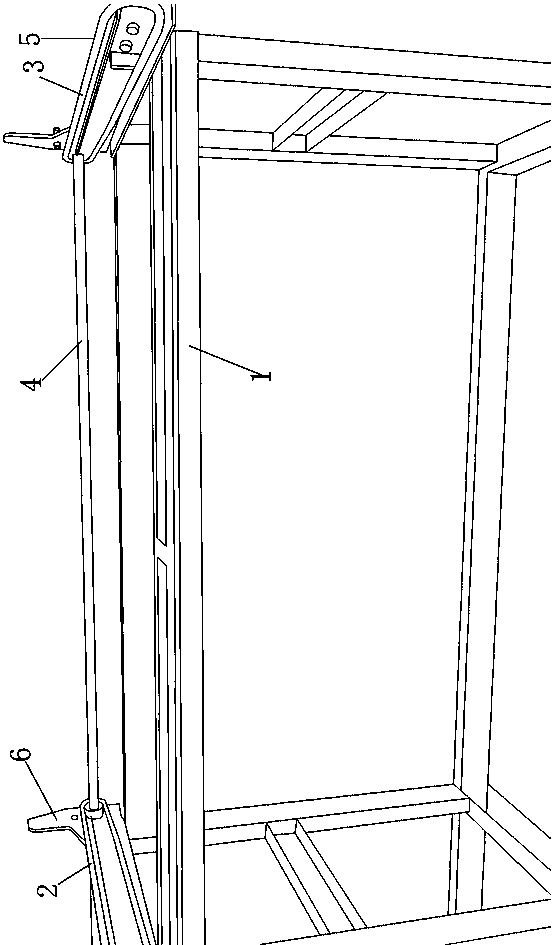

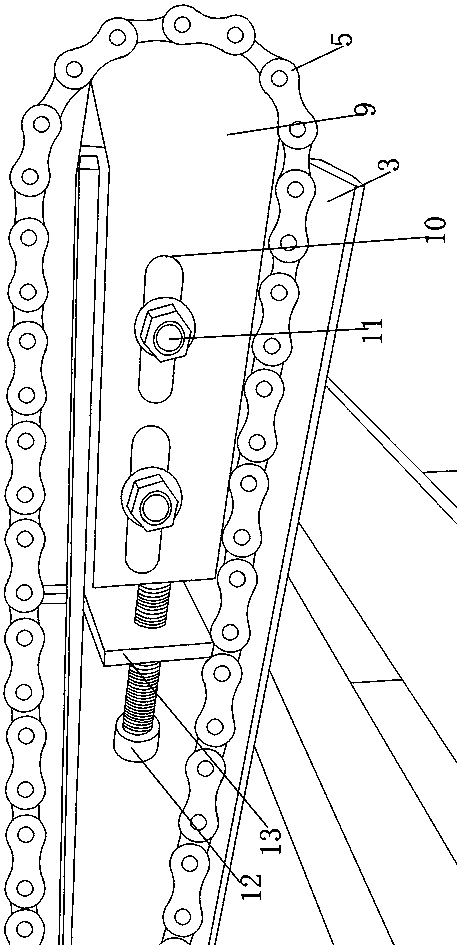

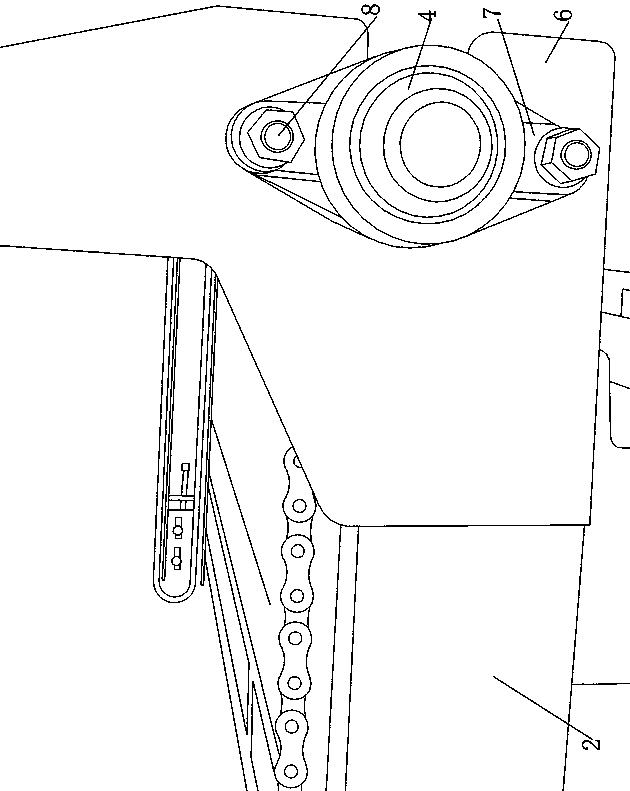

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present embodiment is a numerical control vertical automatic feeding machine, which includes a frame 1, an adjustment device, a left fixed plate 2, a right fixed plate 3, a chain 5, a rotating shaft 4 and a shaft mounting plate 6, and the left The fixed plate 2 and the right fixed plate 3 are respectively arranged on the left and right sides of the frame 1, the adjusting device is installed on the same side of the left fixed plate 2 and the right fixed plate 3, and the rotating shaft 4 is installed between the left fixed plate 2 and the right fixed plate 3 On the other side of the space, the two chains 5 are installed on the left fixed plate 2 and the right fixed plate 3 respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com