Mandrel for molding rubber pipes

A technology of rubber hose and mandrel, applied in coating and other directions, can solve the problems of thick wall, increase production cost, and short service life of mandrel, and achieve the effect of reducing use cost, prolonging service life and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

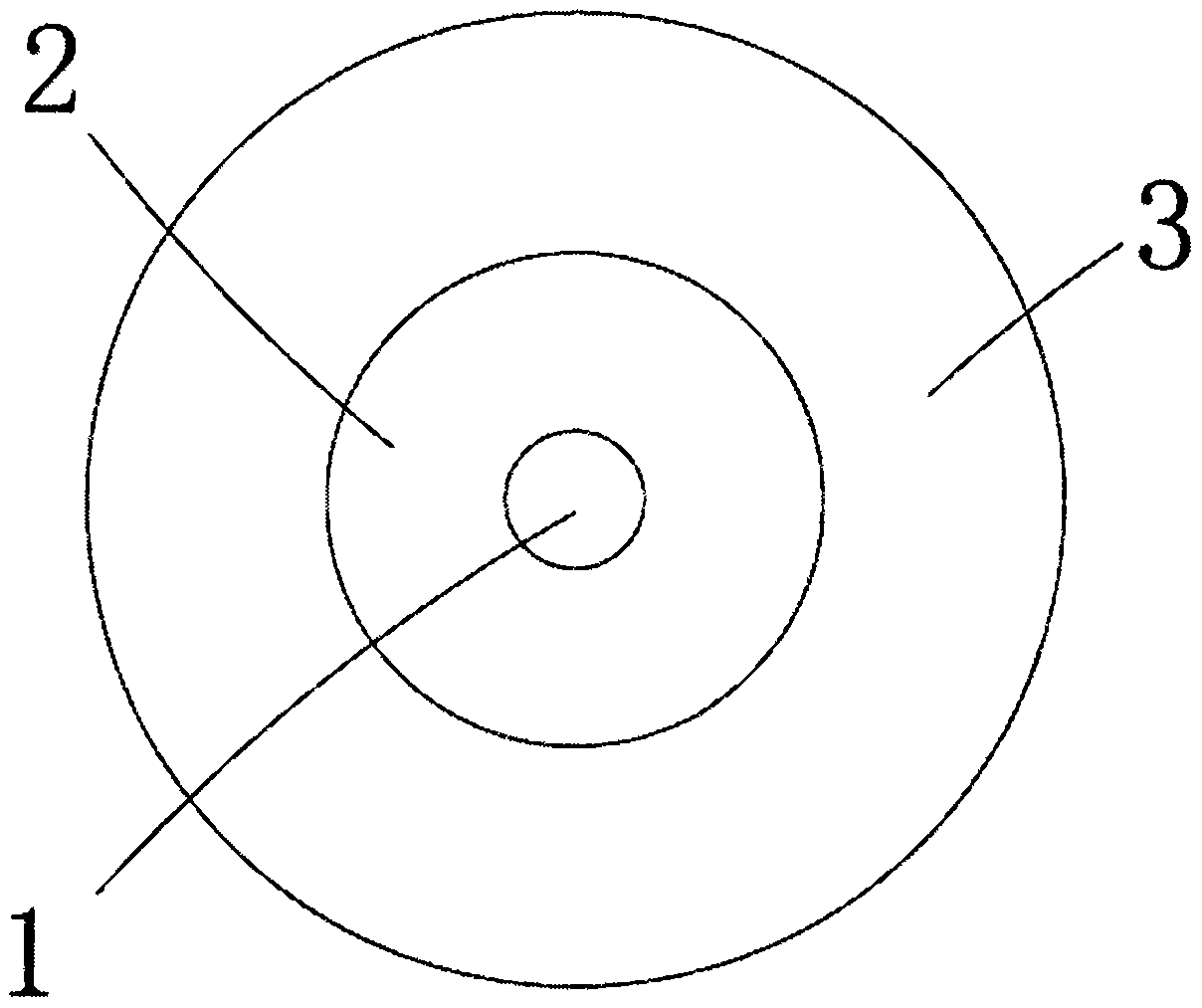

[0019] Such as figure 1 As shown, the mandrel for rubber hose molding includes a central part 1 , a first layer part 2 disposed on the central part 1 and a second layer part 3 disposed on the first layer part 2 . The central part 1 is cylindrical, and the central part 1 is mainly a steel wire rope, and the central part 1 can be bent. The hardness of the central part 1 should not be too small or too large, because when the hardness of the central part 1 When it is small, it tends to cause larger ellipticity in the process of removing the core by high-pressure water, and when the hardness of the central part 1 is relatively high, it is difficult to roll it up because it is not easy to bend. Wound on a reel. The first layer part 2 is formed on the central part 1 by extrusion, and the first layer part 2 is a cylinder whose cross section is a ring, and the first layer part 2 is made of thermoplastic elastomer material , which are mainly styrene thermoplastic elastomers (such as T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com