Shunting drive system and vehicle with shunting drive system

A drive system and vehicle technology, applied in the field of conventional vehicles and shunting drive systems, can solve problems such as huge investment costs, and achieve the effects of saving expenses, avoiding losses, and being easy to assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

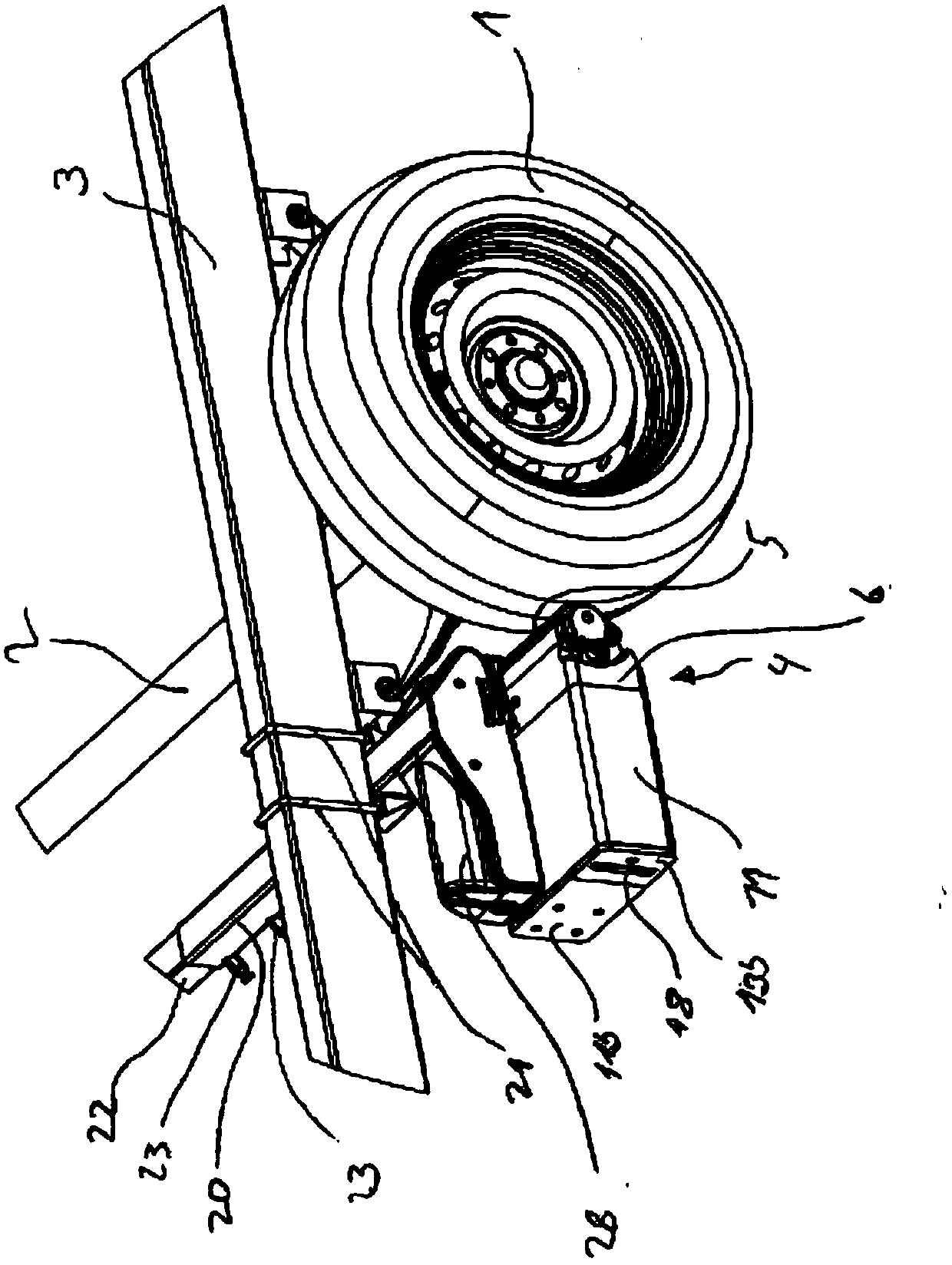

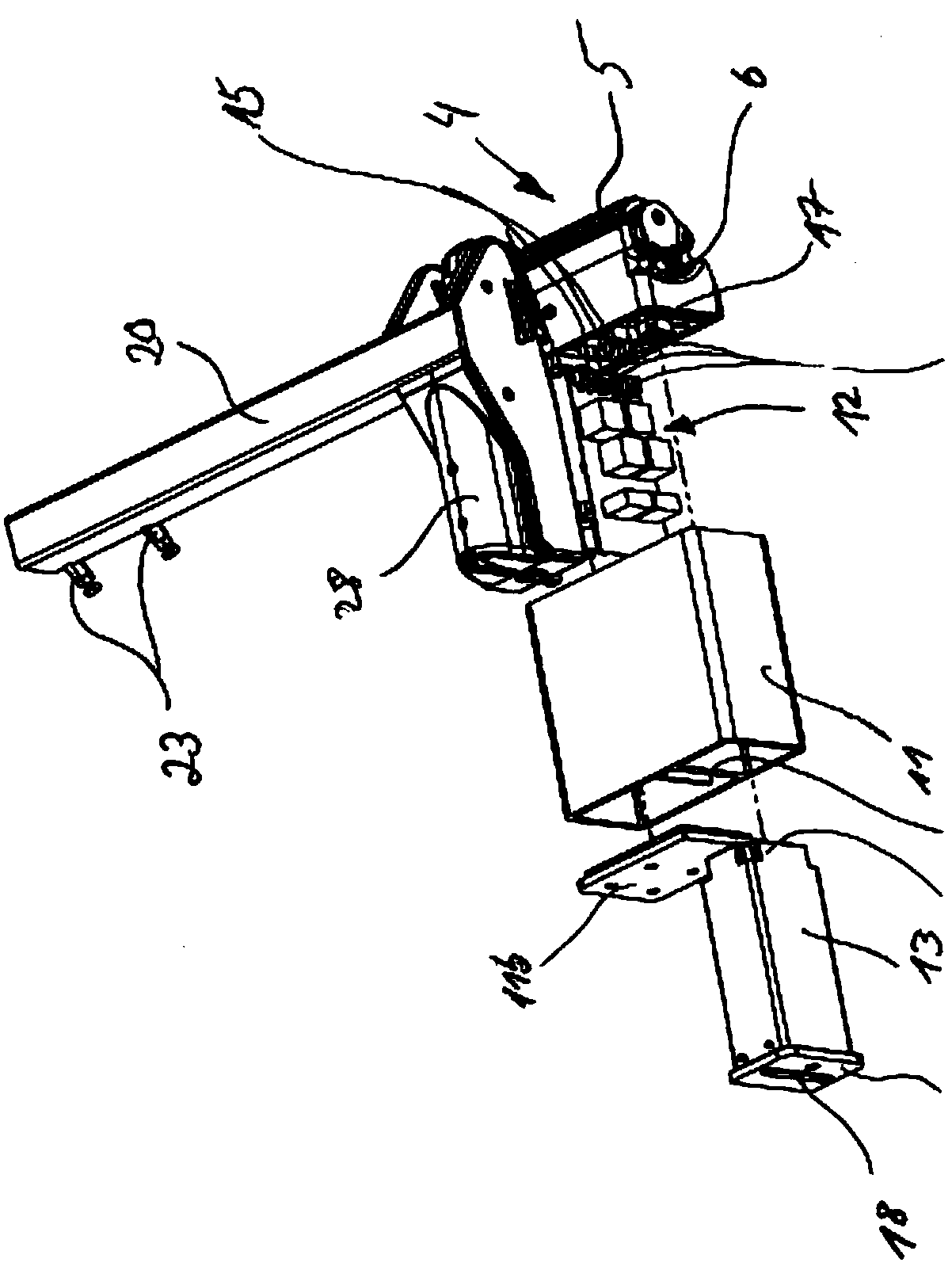

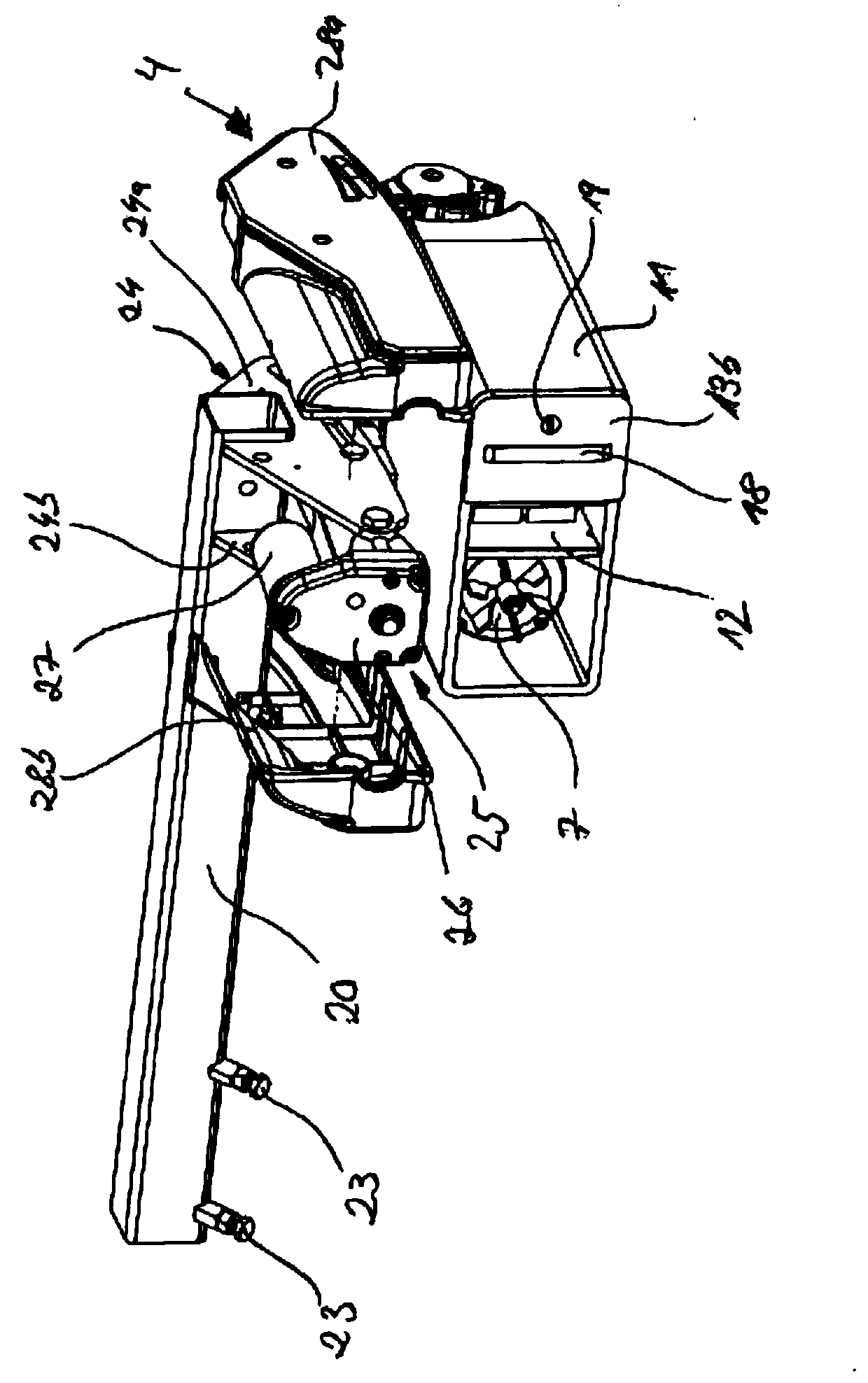

[0054] figure 1 Wheels 1 , axles 2 and side members 3 of the vehicle chassis of the vehicle, which are not further illustrated in the figures, are shown, in this case a boat trailer. The wheel axle 2 and the side members 3 are only partially shown in the figure.

[0055] The trailer does not have its own drive and can be difficult to move by hand, especially maneuvering, if it is not connected to the PKW used as a tractor. A trailer with the shunting drive system according to the invention is therefore designed. This trailer consists of two drive units 4, in figure 1 Only the one of the two drive units provided for the wheel 1 shown here can be seen. The other drive unit 4 of the shunting drive system is similarly provided for the second wheel 1 which is arranged on the wheel axle 2 at the figure 1 on the other end not shown. Via the two drive units 4 , the wheels 1 of the trailer can be rotated and the trailer can also be moved, in particular shunted, without a tractor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com