Discharging device of stainless steel strips or coils

A technology of stainless steel strip and steel coil, which is applied in the directions of winding strips, thin material processing, transportation and packaging, etc. It can solve the problems of stainless steel processing operations, stainless steel strips and coils cannot be discharged normally and stably, and achieve synchronization Sexual operation, ingenious design, to ensure normal and stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

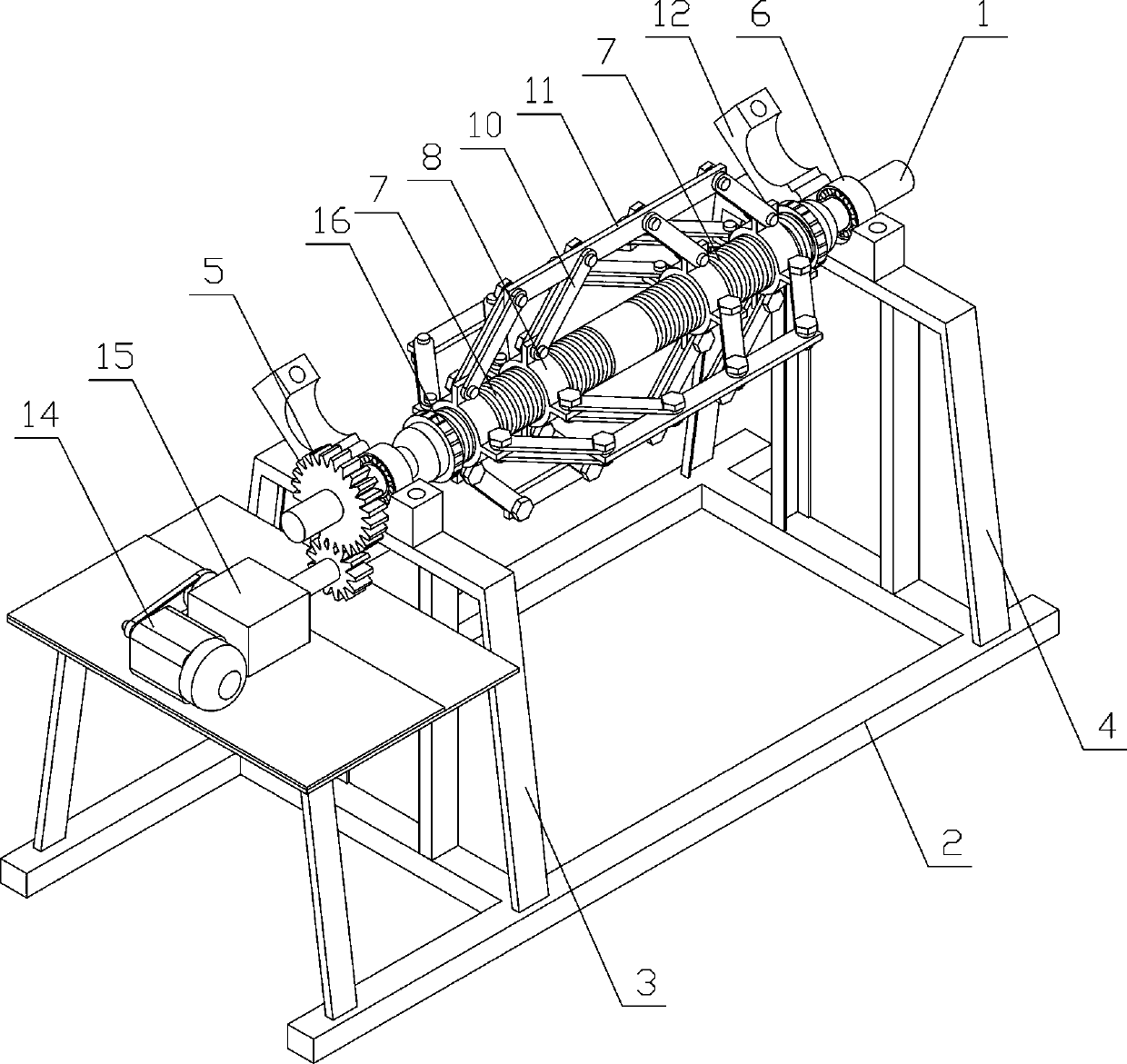

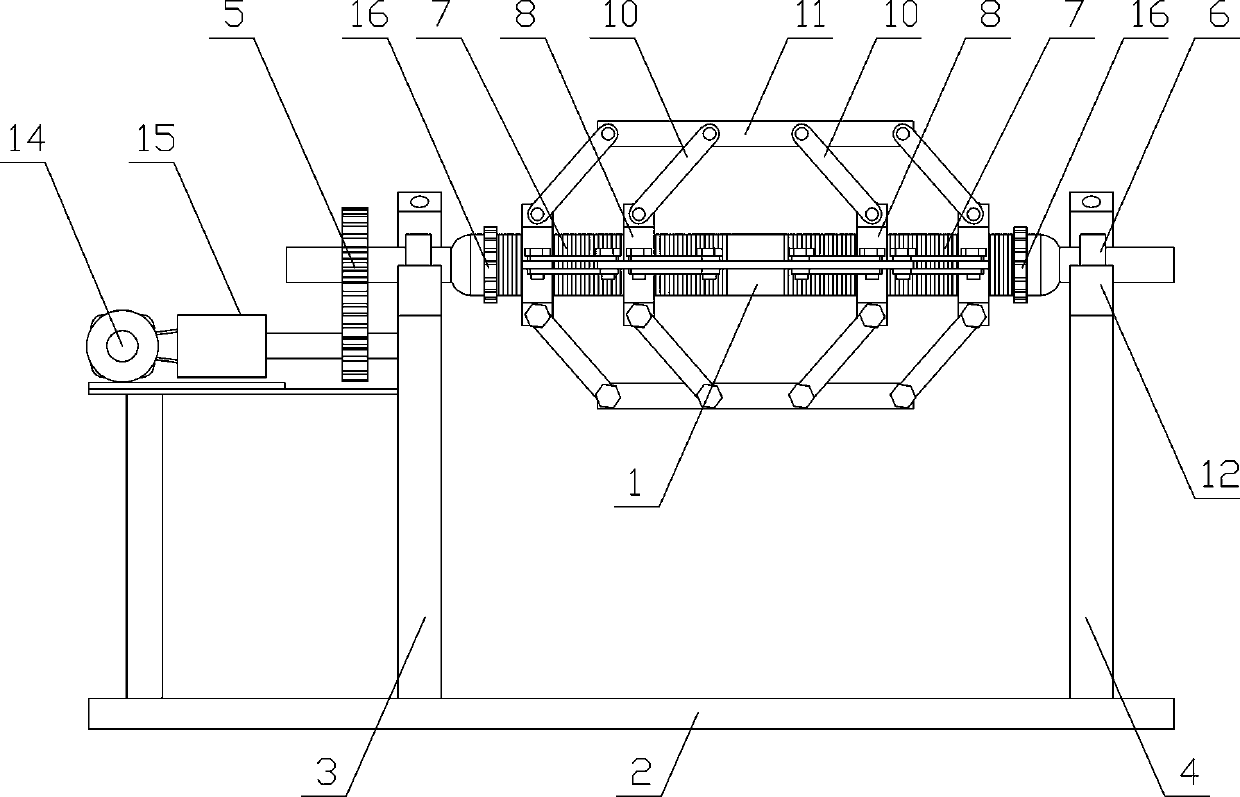

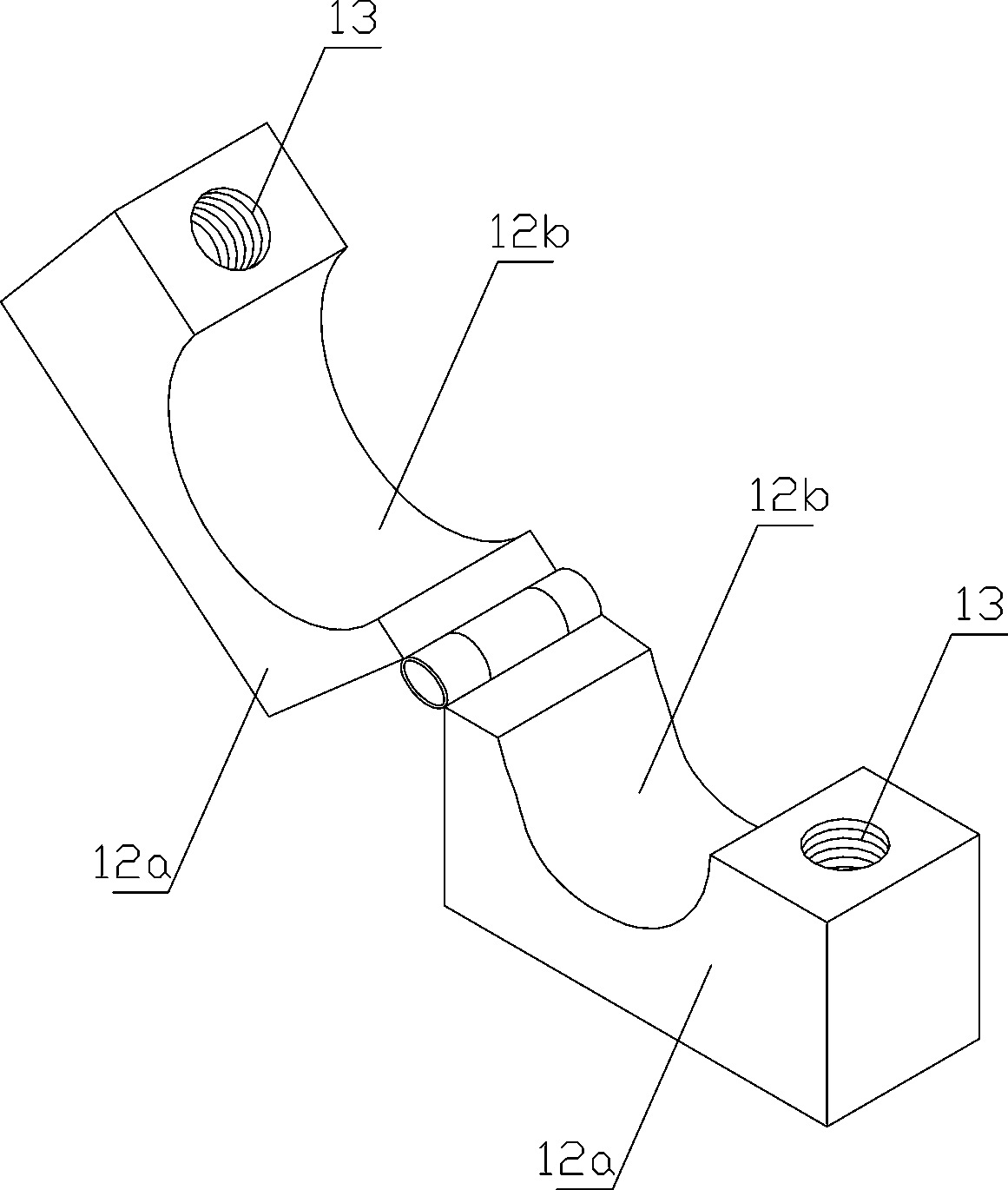

[0016] see Figure 1-2 , the present invention comprises frame and rotating shaft 1, and frame is made up of base 2 and left and right supporting frame 3,4, and one end of rotating shaft 1 is connected driving mechanism by gear transmission mechanism 5; Especially: in left and right supporting frame 3 , 4 are provided with fastening devices 12 correspondingly arranged on the left and right sides, which are used to lock the bearings 6 arranged at the left and right ends of the rotating shaft 1 respectively; Several adapter rings 8 are set on the section thread structure 7, and several connectors 9 are evenly distributed on the adapter ring 8, and the connectors 9 on the adapter rings 8 on the left and right sides of the rotating shaft 1 correspond to each other one by one, and Each group of left and right one-to-one corresponding connectors 9 are respectively hinged to the same support rod 11 through the adapter rod 10, that is, one end of each transfer rod 10 is hinged to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com