Equipment for rapidly and precisely cutting glass curtain wall

A glass curtain wall and cutting equipment technology, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problem of scratching people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

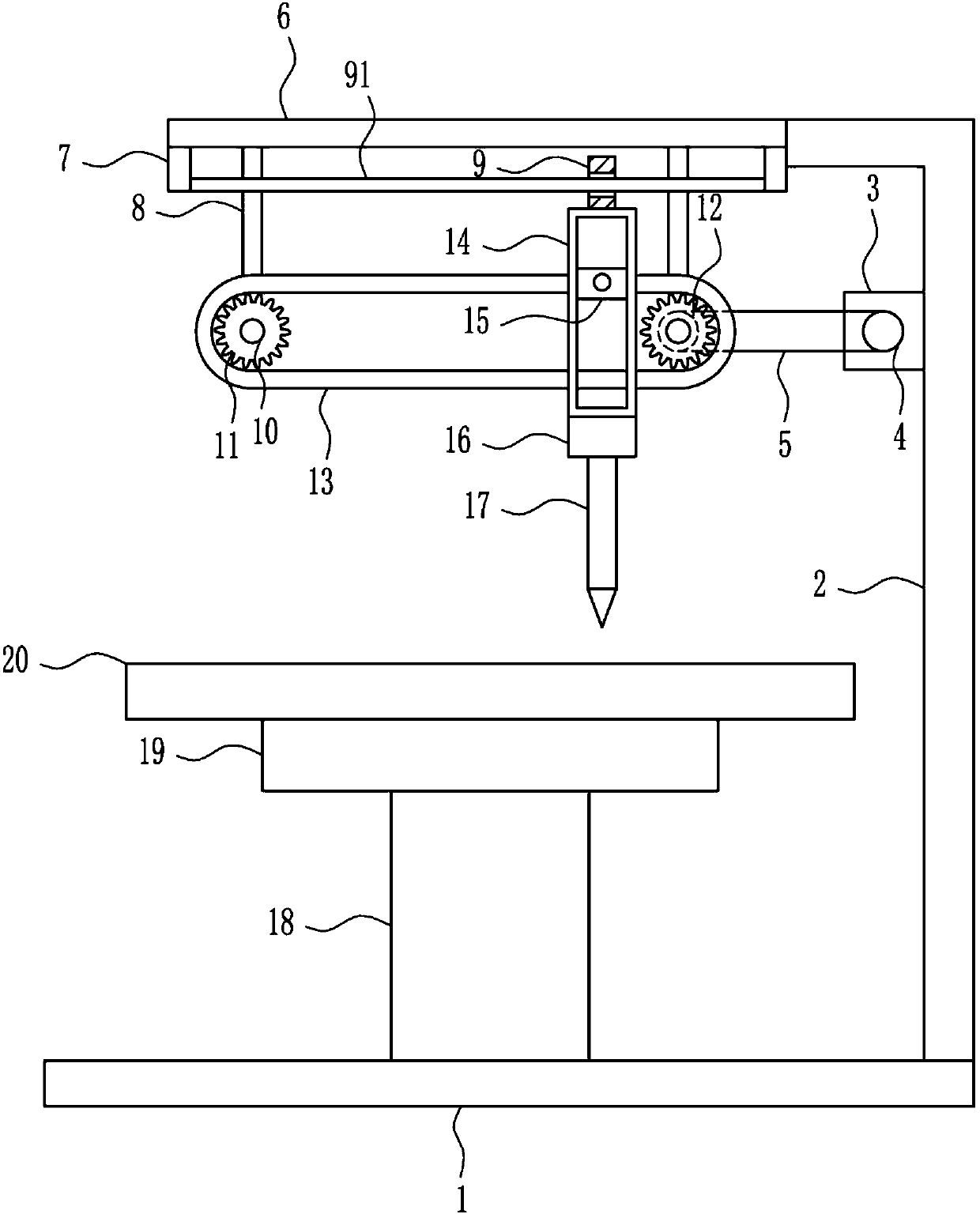

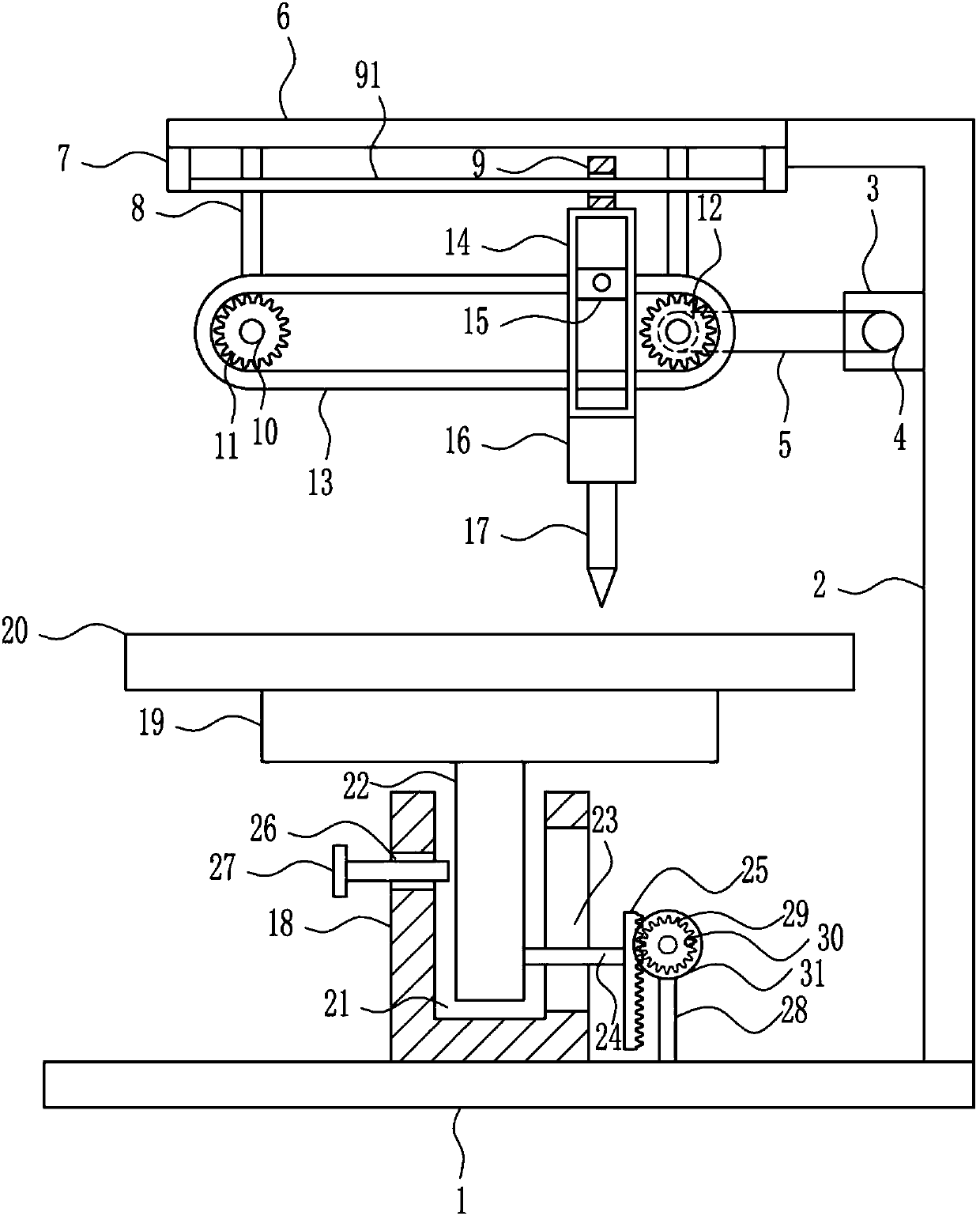

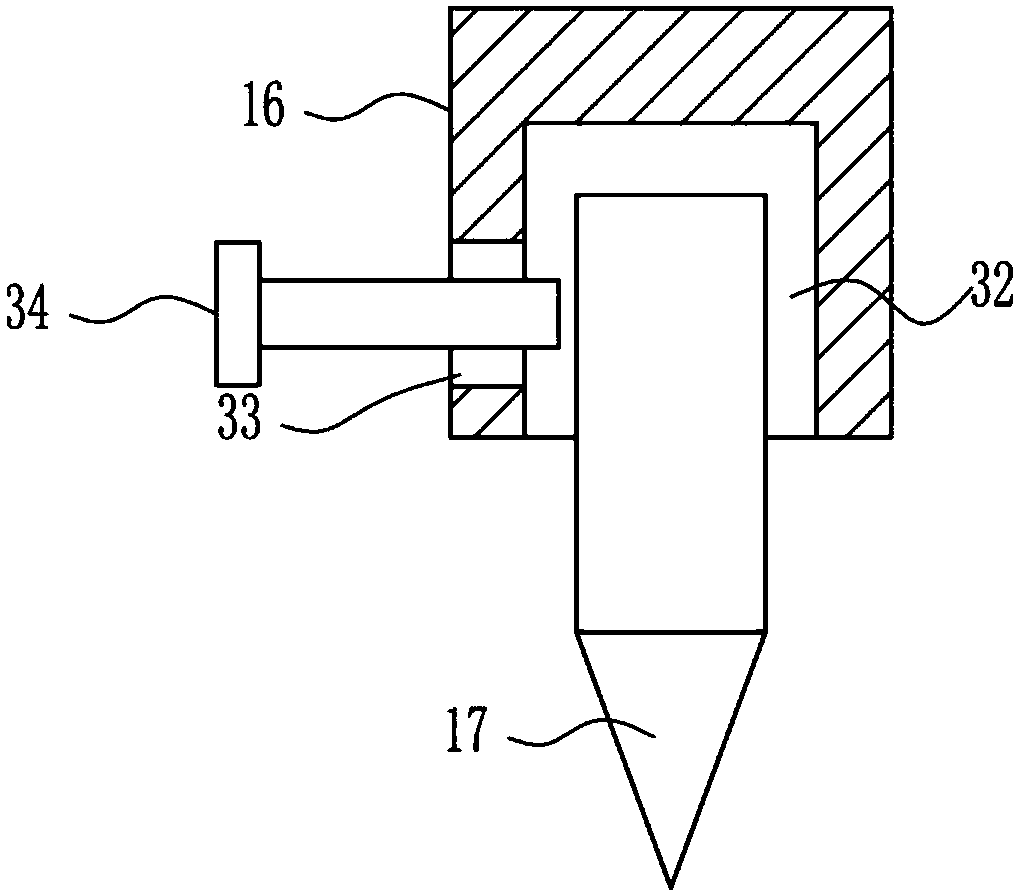

Embodiment 1

[0023] A fast and precise cutting equipment for glass curtain walls, such as Figure 1-3 As shown, it includes a bottom plate 1, a bracket 2, a motor 3, a first pulley 4, a transmission bar 5, a mounting plate 6, a connecting block 7, a first support rod 8, a guide sleeve 9, a guide rod 91, a rotating shaft 10, a first Gear 11, second pulley 12, chain 13, slide rail 14, slide block 15, fixed block 16, diamond knife 17, base 18 and placement platform 19, support 2 is connected on the right side of the upper side of bottom plate 1, and the right wall of support 2 is left A motor 3 is installed on the upper side, the first pulley 4 is connected on the output shaft of the front side of the motor 3, the left end of the upper wall of the support 2 is connected with a mounting plate 6, and the left and right sides of the rear side of the mounting plate 6 are connected with a first support rod 8, two The first support bar 8 is connected with a rotating shaft 10 in the rotation type be...

Embodiment 2

[0025] A fast and precise cutting equipment for glass curtain walls, such as Figure 1-3As shown, it includes a bottom plate 1, a bracket 2, a motor 3, a first pulley 4, a transmission bar 5, a mounting plate 6, a connecting block 7, a first support rod 8, a guide sleeve 9, a guide rod 91, a rotating shaft 10, a first Gear 11, second pulley 12, chain 13, slide rail 14, slide block 15, fixed block 16, diamond knife 17, base 18 and placement platform 19, support 2 is connected on the right side of the upper side of bottom plate 1, and the right wall of support 2 is left A motor 3 is installed on the upper side, the first pulley 4 is connected on the output shaft of the front side of the motor 3, the left end of the upper wall of the support 2 is connected with a mounting plate 6, and the left and right sides of the rear side of the mounting plate 6 are connected with a first support rod 8, two The first support bar 8 is connected with a rotating shaft 10 in the rotation type bel...

Embodiment 3

[0028] A fast and precise cutting equipment for glass curtain walls, such as Figure 1-3 As shown, it includes a bottom plate 1, a bracket 2, a motor 3, a first pulley 4, a transmission bar 5, a mounting plate 6, a connecting block 7, a first support rod 8, a guide sleeve 9, a guide rod 91, a rotating shaft 10, a first Gear 11, second pulley 12, chain 13, slide rail 14, slide block 15, fixed block 16, diamond knife 17, base 18 and placement platform 19, support 2 is connected on the right side of the upper side of bottom plate 1, and the right wall of support 2 is left A motor 3 is installed on the upper side, the first pulley 4 is connected on the output shaft of the front side of the motor 3, the left end of the upper wall of the support 2 is connected with a mounting plate 6, and the left and right sides of the rear side of the mounting plate 6 are connected with a first support rod 8, two The first support bar 8 is connected with a rotating shaft 10 in the rotation type be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com