Whole-process manufacturing supervision closed-loop management system and method based on triple early warning

A management system and whole-process technology, applied in the field of closed-loop management system for whole-process manufacturing supervision based on triple early warning, can solve problems such as the inability to realize the whole-process manufacturing supervision of large-scale equipment, achieve easy interrelation and call, improve judgment and analysis basis , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

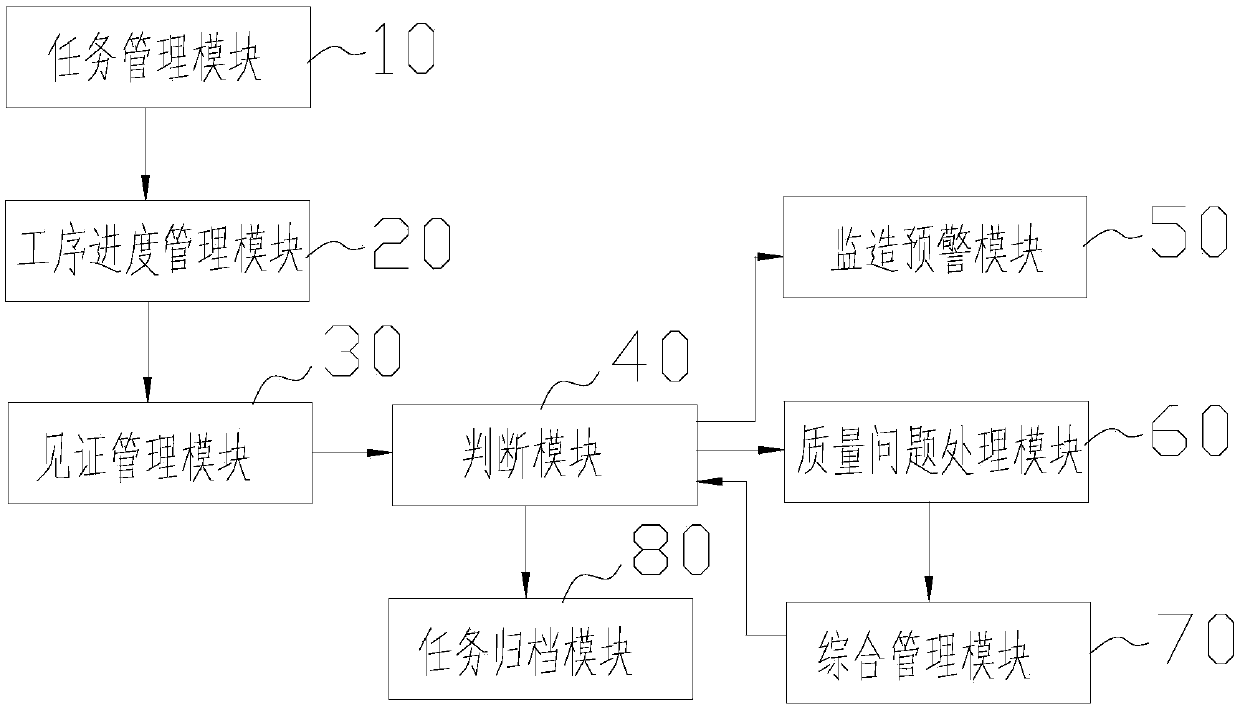

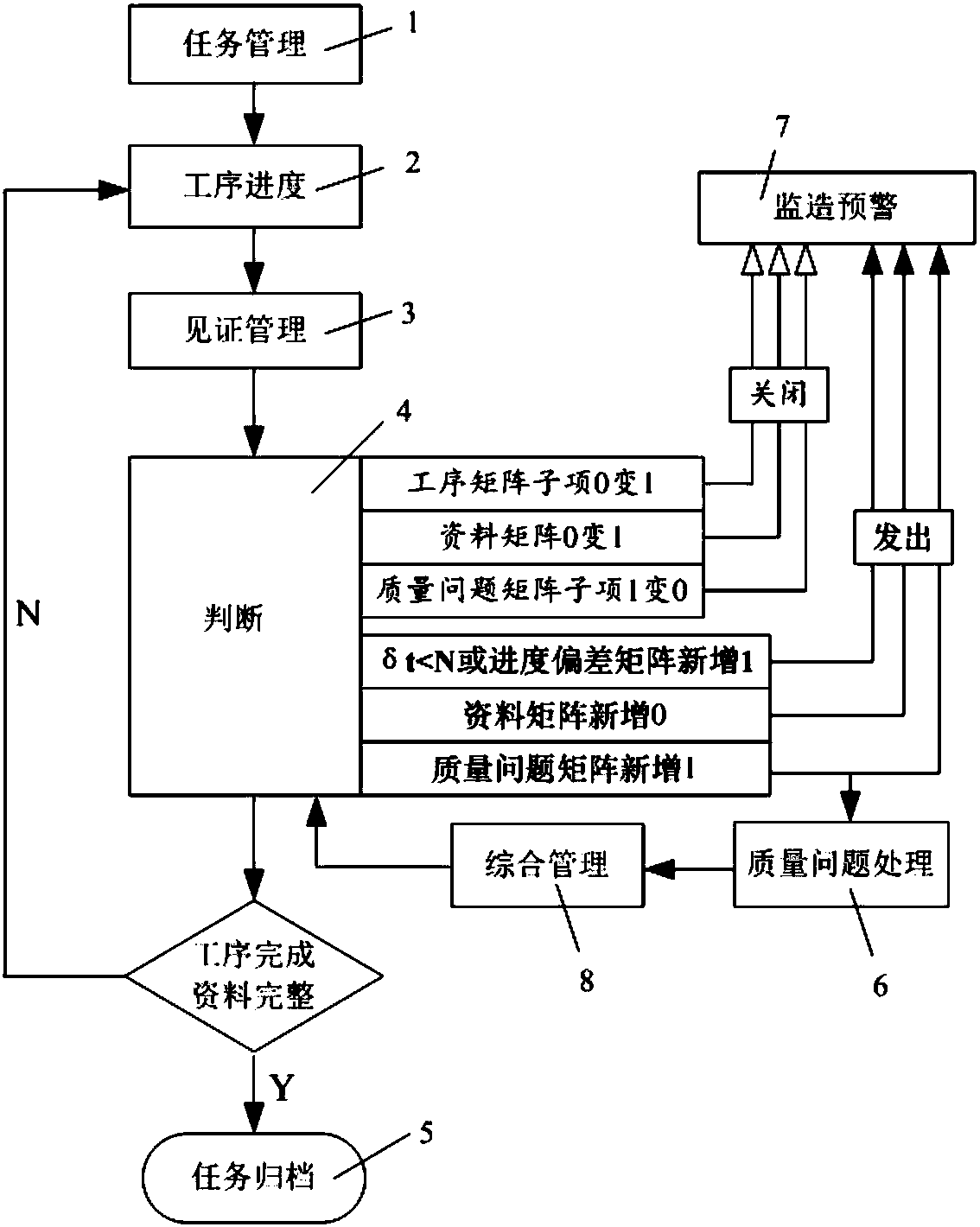

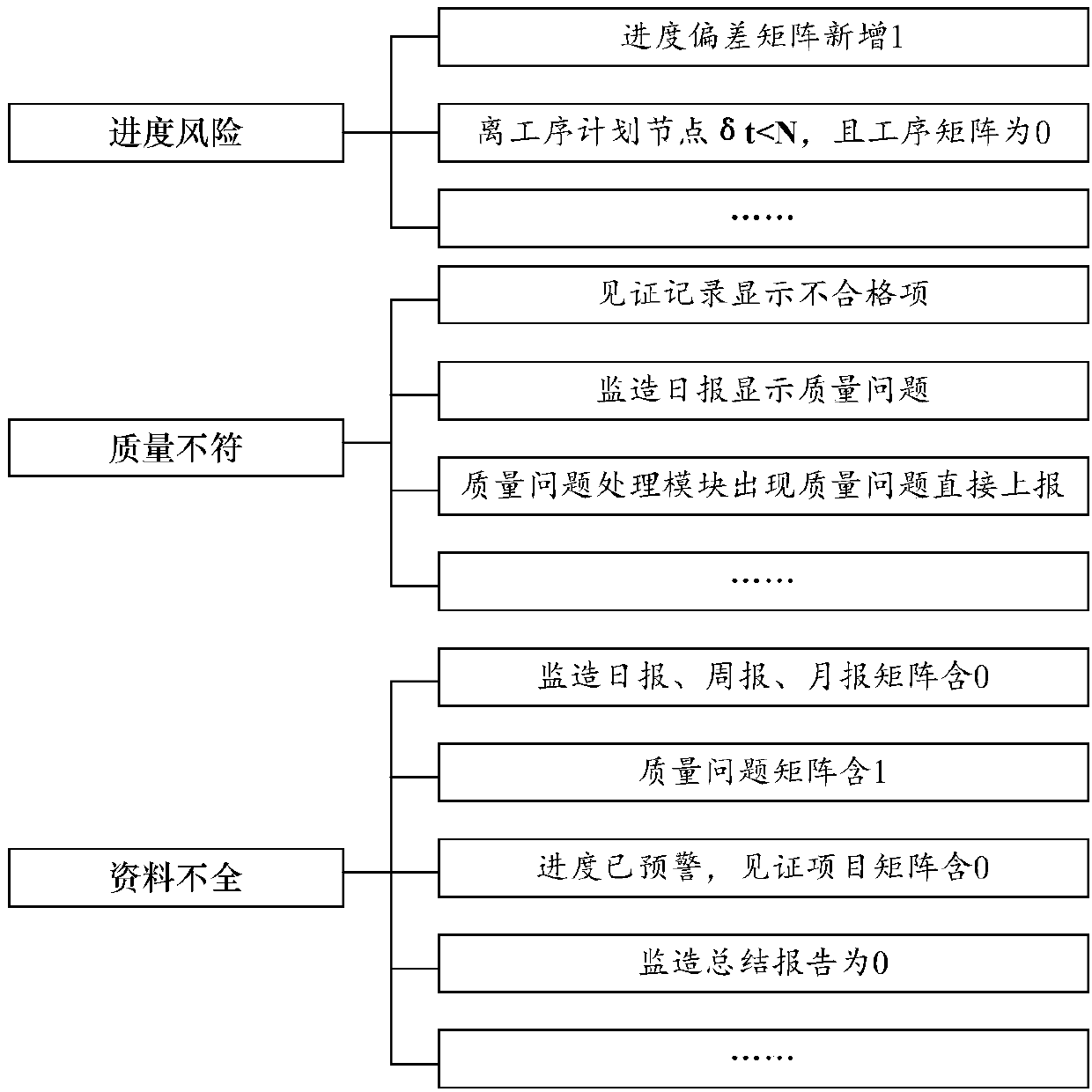

[0042] In the present invention, the task management module 10 takes a single piece of equipment as a task unit and includes basic information about equipment manufacturing. Equipment manufacturing is divided into several major processes. Information, actual completion information, if the witness projects in each process are all completed and the quality problems are all closed-loop, then the task process is completed, and the supervisors fill in the witness projects and daily reports in the witness management module 30. Record and judge production progress, quality problems, and task completion based on documents and historical case bases, etc. The manufacturing supervision and early warning module 50 provides early warnings and alarms for production progress deviations and quality problems, and the own...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com