Full-automatic die bonder

A crystal-bonding machine, fully automatic technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as low production efficiency, hinder production process, unfavorable industrialized large-scale production, etc., to improve productivity and improve intelligence The effect of streamlining operations and reducing labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

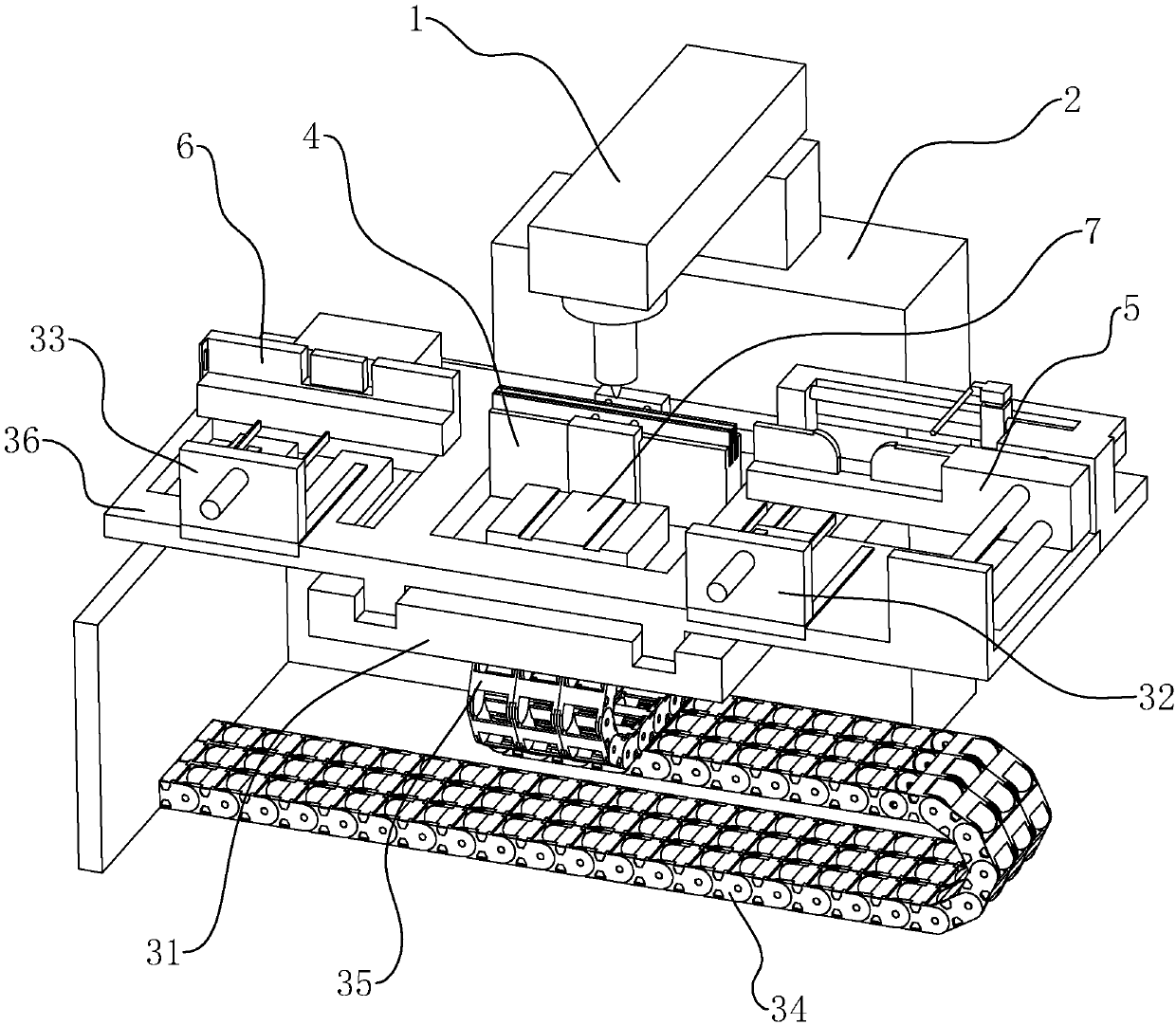

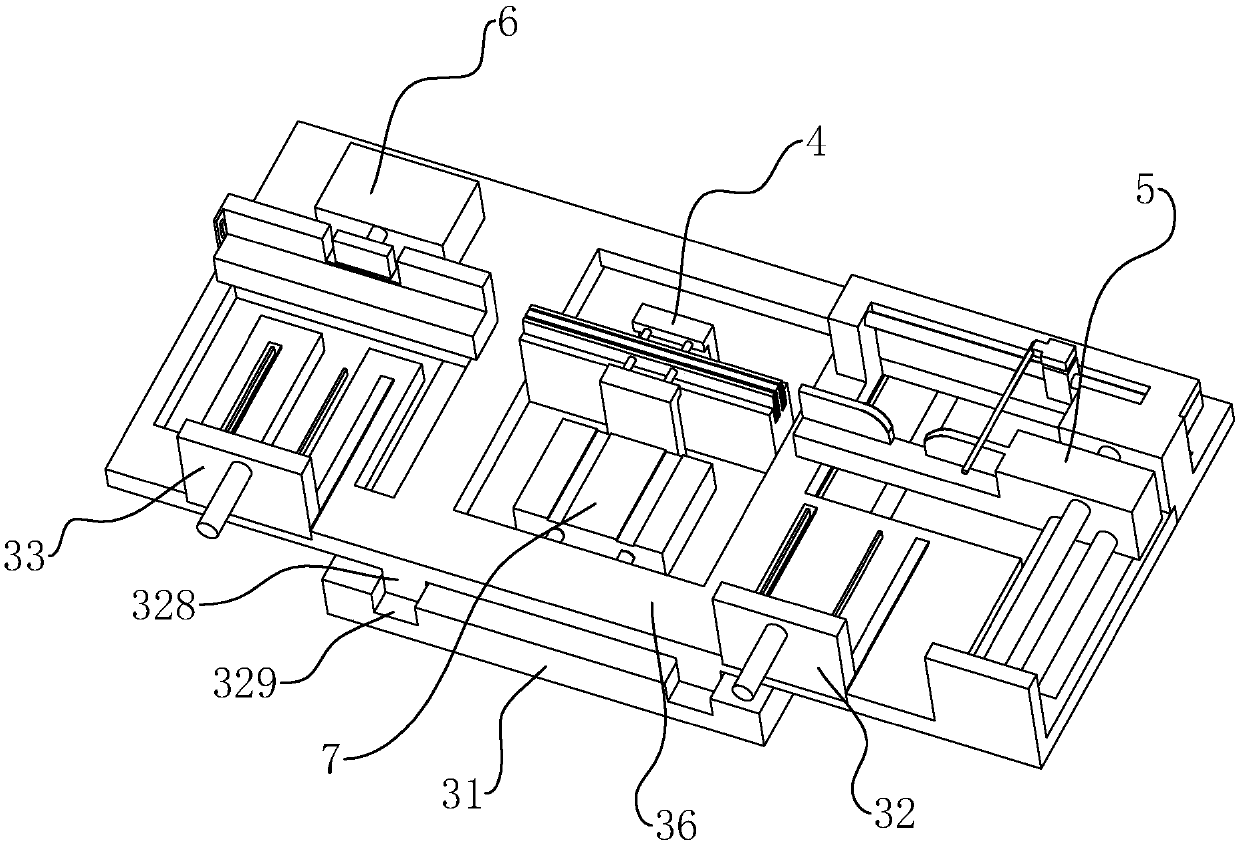

[0035] refer to Figure 1 to Figure 7 Further explain the fully automatic crystal bonder.

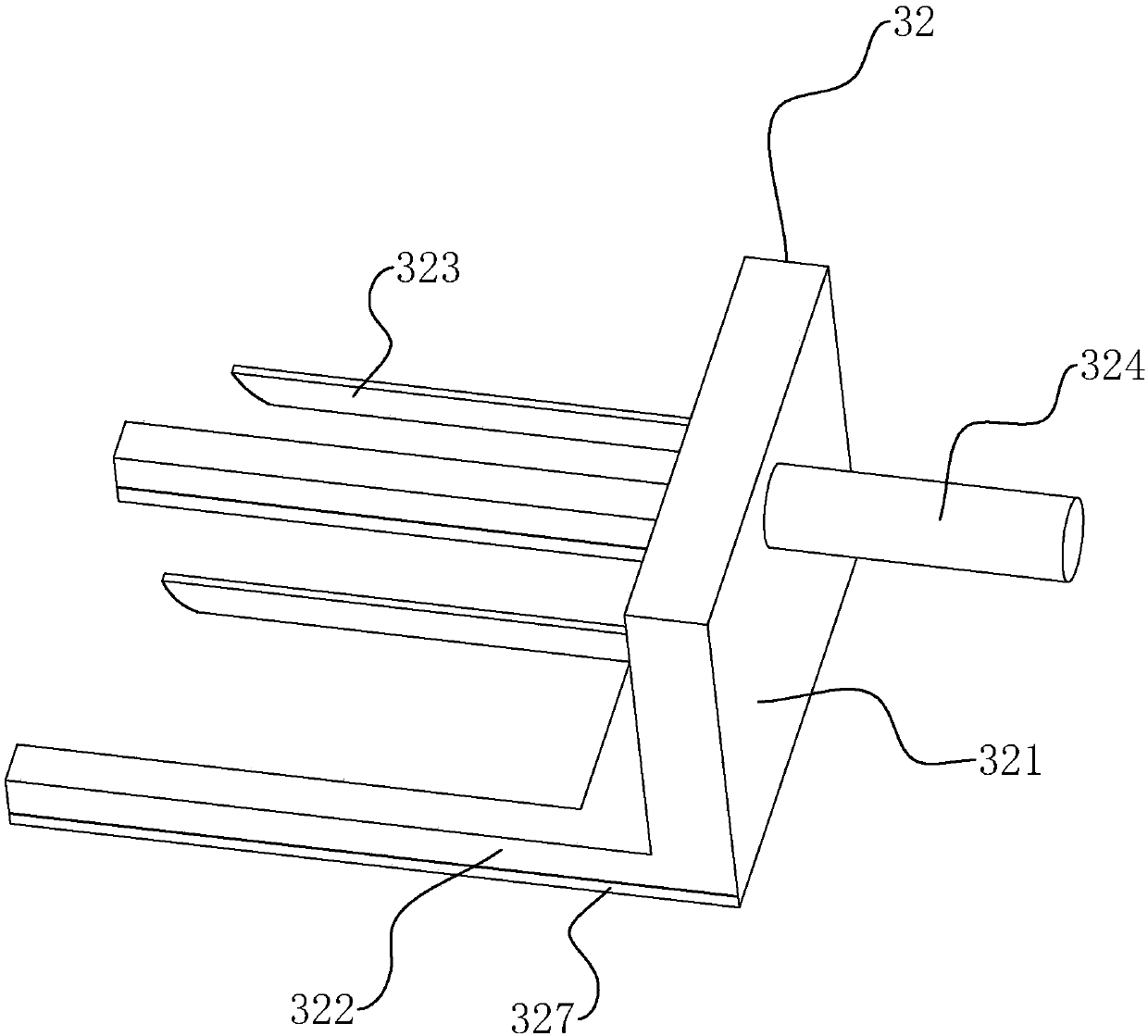

[0036] A fully automatic crystal bonder, such as figure 1 As shown, it includes three modules: an automatic feeding push and clamping device, a dispensing module 1 and an automatic receiving device; specifically includes a frame 2, a mounting frame 31 arranged on the frame 2, and a mounting frame 31 arranged on the mounting frame 31. The loading rack 32 for typesetting LED legs and the receiving rack 33 for receiving materials are arranged between the mounting frame 31 and the frame 2 for driving the mounting frame 31 to reciprocate horizontally on the frame 2 The moving transverse driving mechanism 34, the placing frame 36 arranged on the mounting frame 31, the longitudinal driving mechanism 35 arranged between the horizontal driving mechanism 34 and the mounting frame 31 for driving the placing frame 36 to reciprocate longitudinally on the mounting frame 31, The clamping mechanism 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com