A liquid metal battery anti-corrosion sealing structure and assembly method thereof

A liquid metal battery, sealing structure technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of large space occupied by preparation costs, affecting battery space utilization, complex structure, etc., to prevent leakage of liquid sealing salt risk, optimize space utilization, and improve the effect of liquid sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The device structure and method are respectively described below:

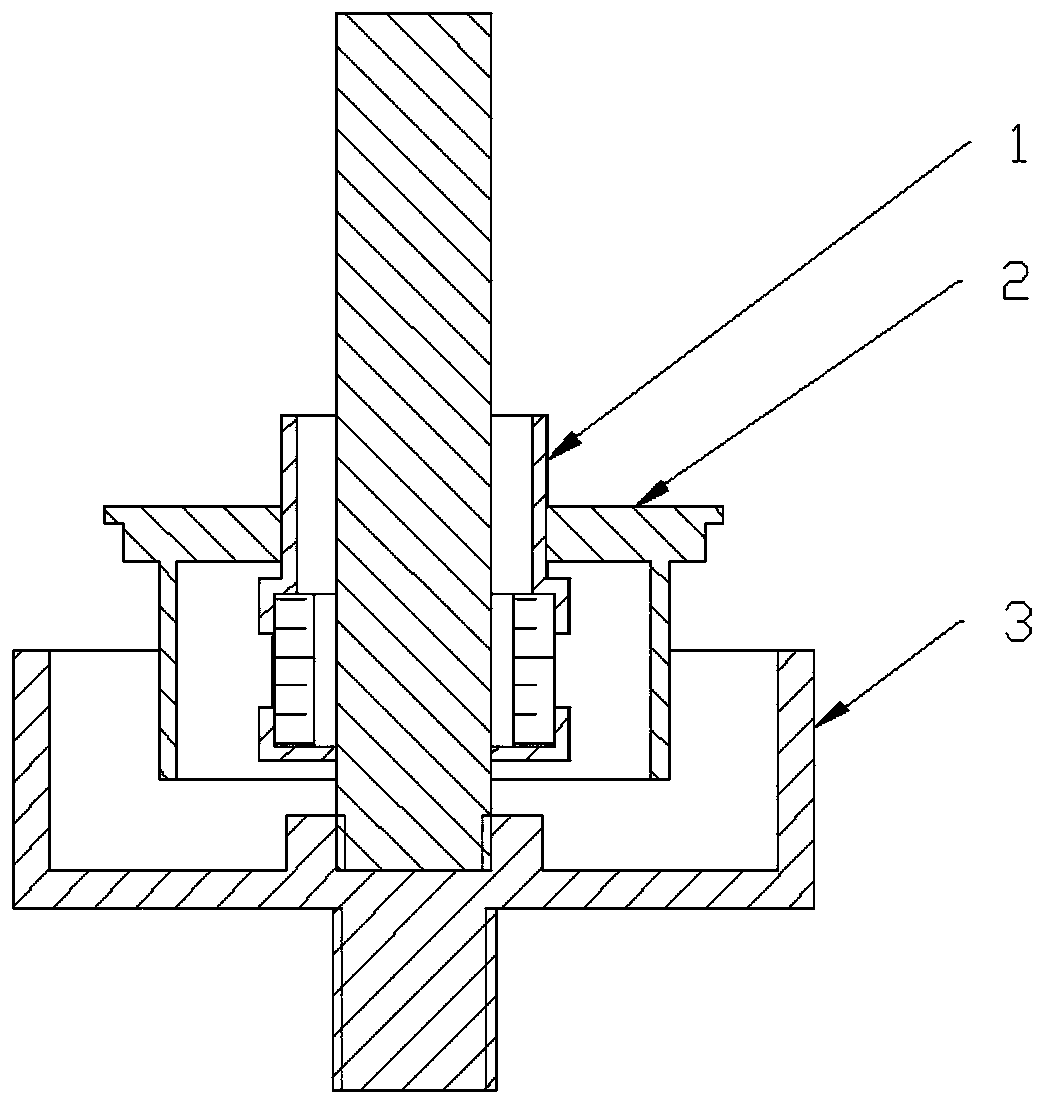

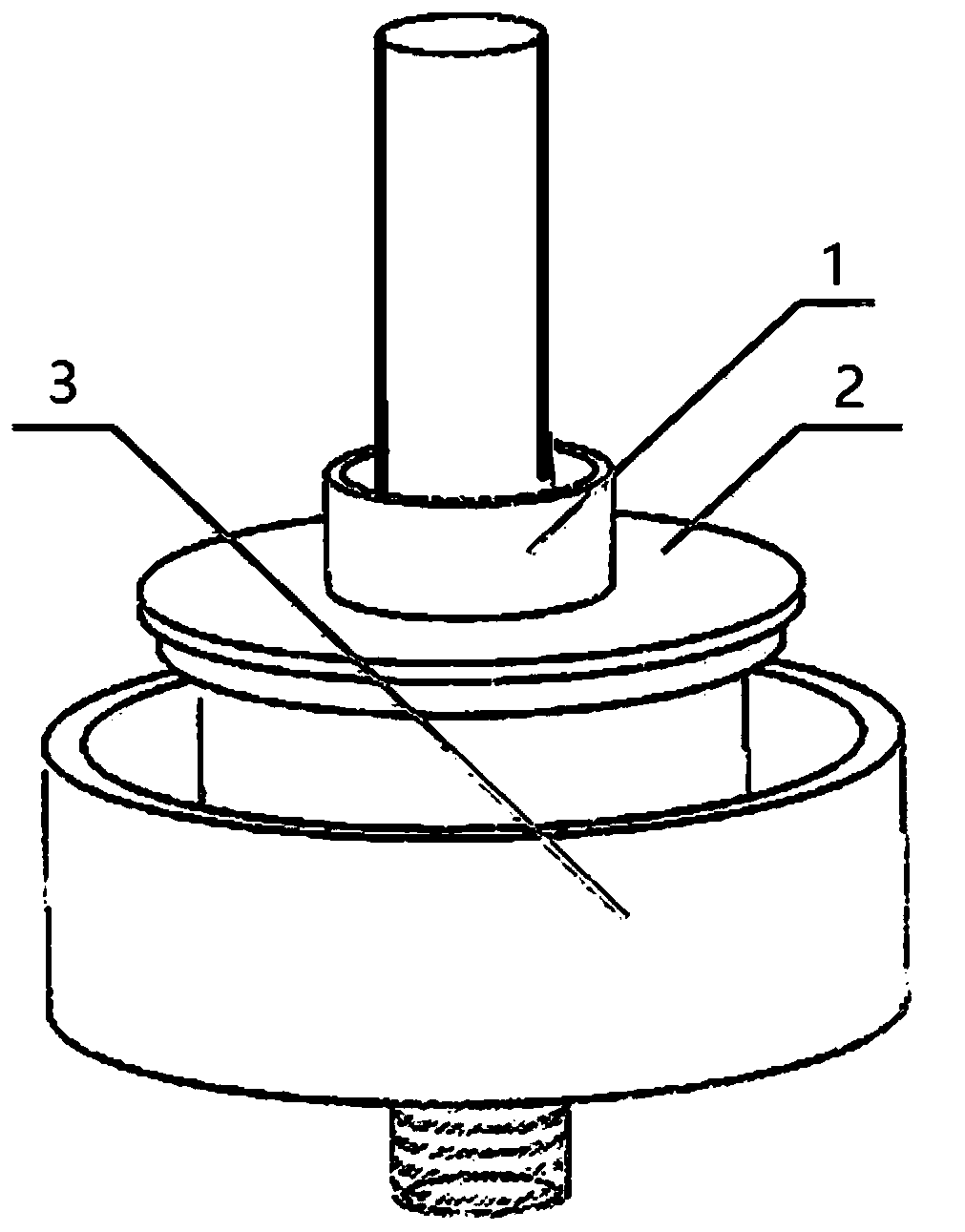

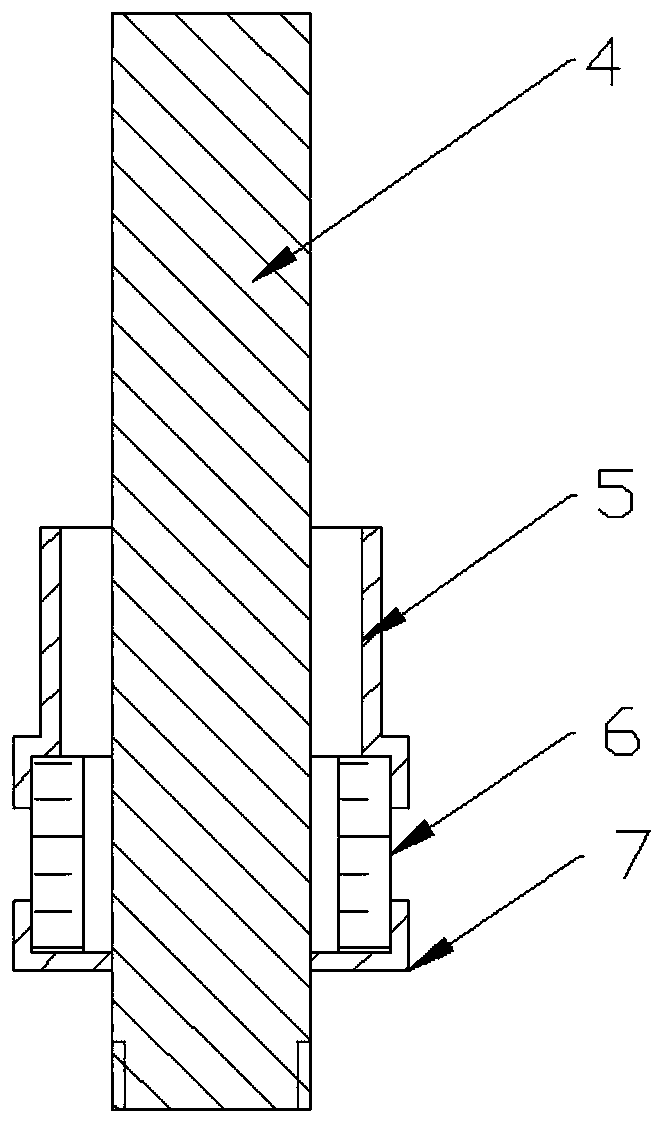

[0035] see Figure 1-3 , a liquid metal battery anti-corrosion sealing structure, including a liquid metal battery sealing electrode 1, a cover plate 2 with a liquid sealing wall and a liquid sealing bowl holder 3; the insulating part 6 in the liquid metal battery sealing electrode 1 is made of ceramic material, The upper transition piece 5 and the lower transition piece 7 are made of Kovar alloy material, and the electrode core 4 is made of stainless steel, copper, Kovar alloy and other metal materials for processing and manufacturing; the cover plate 2 with liquid-sealed wall and the liquid-sealed bowl support 3 are made of stainless steel, etc. Corrosion-resistant materials; liquid metal battery sealing electrode 1, cover plate 2 with liquid-sealed wall, and liquid-sealed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com