Efficient electric radiant tube heater

A technology of electric radiant tube and heater, which is applied in the direction of ohmic resistance heating components and the shape of heating elements, etc., can solve the problems of reduced thermal efficiency of electric radiant tube heaters, reduce heat transfer, improve thermal efficiency and service life, and save energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

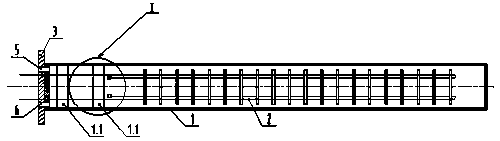

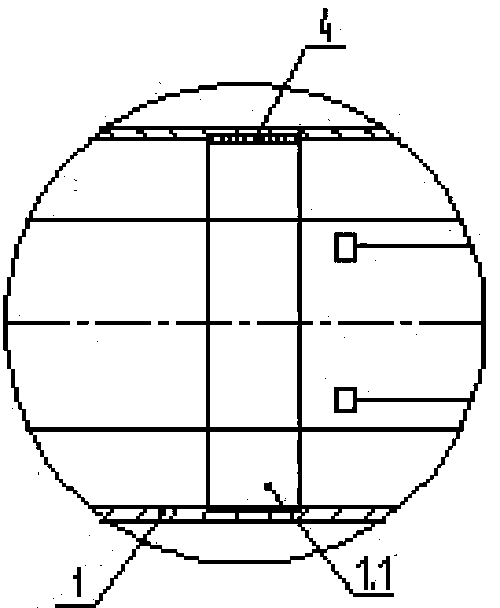

[0017] The high-efficiency electric radiant tube heater shown in the accompanying drawings includes a straight cylindrical radiant tube 1, a heater 2 arranged in the radiant tube 1, and a tube cover 3; the tube cover 3 is closed on the port of the radiant tube 1; There are an upper through hole 5 and a lower through hole 6 communicating with the inner cavity of the radiant tube 1 .

[0018] The radiant tube 1 is provided with two annular partition grooves 1.1 on the inner wall between the end of the heater 2 and the tube cover 3 .

[0019] The partition tank 1.1 is provided with a high-temperature resistant non-metallic material 4, and in this embodiment, the high-temperature resistant non-metallic material 4 is high-temperature resistant ceramic clay.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com